Overview

Transforming the economics of mature gas fieldsOur subsea gas-compression systems are designed and developed with industry partners to significantly improve the economics of mature gas fields. We have extensive experience in designing subsea compression systems for both dry-gas and wet-gas applications, with power from topside or subsea power-distribution systems.

Robust power solutionsOur compression systems combine the best technologies from the Baker Hughes Store, including condition monitoring, electrical actuators, acoustic leak detection, and control systems—all supported by robust power solutions for both short and long step-out distances.

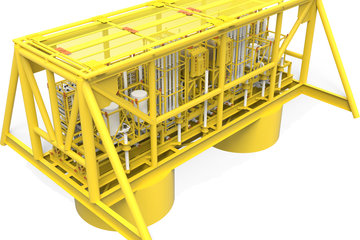

Eliminating costly facilitiesAs gas is produced, reservoir pressure decreases and may become insufficient to maintain the flow. Traditionally, production has been optimized by either reducing arrival pressure onshore or compressing the gas on a platform. Now, we can place compression systems on the seafloor, eliminating the need for costly topside facilities and reducing your overall health, safety and environment concerns.

Ultra-efficient compressionBaker Hughes is able to provide a fully-integrated subsea compression system, complete with subsea power distribution. Using our Blue-C™ centrifugal compressors, our subsea compression systems are placed as close to the wellhead as possible to maximize compression efficiency.

Configuration versatilityWhile all subsea compression systems require a reliable high-voltage power supply, the choice of power supply topology depends on the step-out distance and the number and power requirements of the loads. The step-out distance also determines where you place the variable speed drives (VSDs) that control the subsea compressors (topside, on a floating structure, or subsea), and we can accommodate any of these design configurations.

World-leading technologyWe have considerable in-house expertise in the design of high-voltage subsea power systems. We worked with the Ormen Lange license to qualify the world’s first subsea power-distribution system with subsea VSDs, subsea switchgear, and subsea uninterruptable power supplies. This was done in an integrated system string test together with the Blue-C compressor, using an MGV1 electrical motor, at Shell’s Nyhamna gas-processing facility in Norway in 2015.

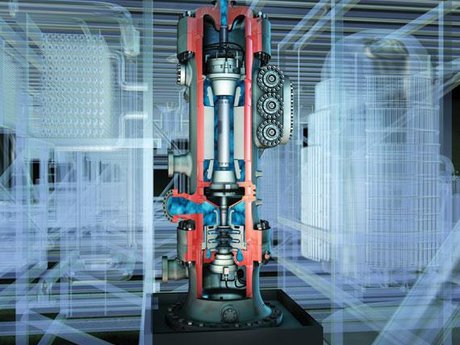

Blue-C compressorOur Blue-C compressor is a high-speed, centrifugal compressor designed for subsea applications. It is at the heart of both our subsea dry-gas and wet-gas compression systems. It comes with a choice of an MGV0, MGV1 or MGV2 high-speed induction motor, which means the compressor can operate at a broad range of power levels, from 4 MW to 20 MW, to best meet your reservoir conditions. As the world’s first centrifugal compressor qualified to handle up to 5% liquid volume fraction (LVF), the Blue-C compressor can support true wet-gas performance for both subsea and topside compression. Compression systems based on the compressor can be tailored to cover almost any operating conditions, providing you with the optimal combination of differential pressure (delta P) and flow.

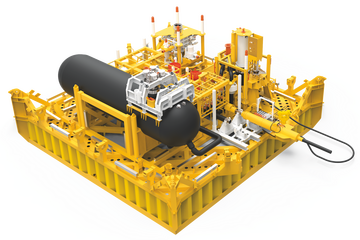

Dry-gas systemsOur dry-gas systems can use active coolers to help reduce size and weight. Dry-gas systems tend to be larger, heavier, and more costly than wet-gas systems. This is because their inherent design requires additional equipment, including a scrubber or separation unit where the liquid phase is separated from the gas. The dry gas is then channeled to the compressor, while the liquid is boosted with a pump. The gas and liquid are then transported through separate or combined pipelines to a floating facility or back to shore. Our extensive experience in designing systems with active rather than passive coolers means an overall reduction in system size and weight.

Wet-gas systemsOur wet-gas systems can handle up to 5% LVF for both subsea and topside applications. Our wet-gas compression systems use a simpler compression system than other industry solutions, eliminating the need for the scrubber, condensate pump and pump control system. The result is a reduction in size and weight of up to 40%, and potential for a 30% reduction in your total CAPEX compared with a conventional dry-gas system. The fundamental requirement of a wet-gas system is that the compressor must be capable of handling gas with up to 5% LVF. Unique to Baker Hughes, we have wet-tolerant impellers that help do this, with special materials and coatings, and modifications to the impeller geometry and compressor flowpath. These innovative impellers have been qualified at Equinor’s K-Lab facility in Norway for use in the Blue-C compressor.

Features and benefits:

|