Highlights

Highlights

Benefits

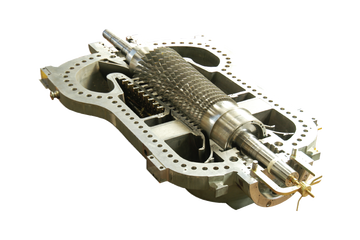

- Double-flow, high-reliability design features high volume flow and high speed with no increase in turbo casing size, matching typical driver speeds

- Continually updated single-stage technology ensures optimal performance in any pressure ratio, including medium or low-pressure applications

- The serviceable, horizontally split design provides access to the rotating element in any train configuration, enhancing industrial asset management

Features

- Customized configuration available: in-line, back-to-back, intermediate cooling, additional side stream

- Flanges up to 86 inches can withstand up to 20 NEMA; 72-inch diameter impellers built with full milling and robot welding

- Complete accordance with API requirements with no gasket in the middle section

Applications

- Petrochemicals, fertilizers, refinery

- LNG

- Air separation

Overview

Overview

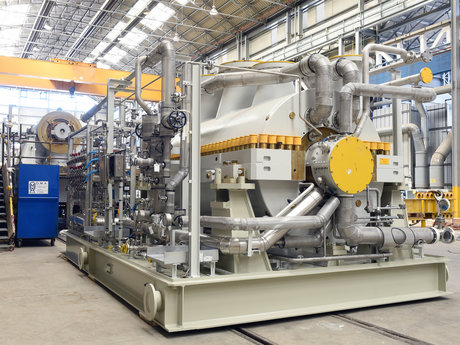

Our high-efficiency horizontally split MCL compressor has a long history of excellence, primarily in the LNG turbomachinery and automation market. Thanks to its configuration in full API compliance, it can easily manage the highest flow rate–ensuring high availability and reliability with any driver and easy asset management and maintenance, reducing operation downtime and maximizing uptime.

Specification

Discharge pressure

Up to 60 bar

Inlet flow range

Up to 600,000 m3/h

Max number of phases

Up to 3 phases

Speed

Up to 20,000 rpm

Configuration

In line, back-to-back, double flow

CO2 compression capabilities

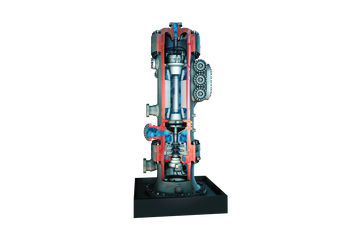

Baker Hughes has an extensive portfolio evolved from proven products and more than 50 years of experience in CO2 compression. Our equipment is operating in more than 90 plants, and we have new developments to maximize performance for carbon-capture applications. The typical train arrangement includes a steam turbine or electric motor driving a high-speed barrel compressor through an increasing gearbox or a pump for CO2 compression applications. We can also provide a plug-and-pay solution fully integrated with a multistage pump.

Besides our traditional product portfolio, we have equipment operating at the world's largest CO2 compression station, which can reinject more than 3 million tons per year of CO2 from an Australian LNG plant. In recent years, our Power Density approach has reduced footprint and weight while enhancing efficiency and increasing rotation speed. With new materials and coatings for improved resistance to corrosion and stress corrosion cracking, we can manage any sour or acid gas mixture.

Integrated electrically driven package

Our proven compressor technology can be easily integrated to most electric motors in the market. Not only does the electric motor minimize emissions and comply with new regulations, but it's also an efficient choice that's simple to operate, with longer maintenance intervals and significantly lower total cost of ownership. Our in-house services include full system test validation with unique performance testing capabilities for large motor drives up to 100 MW.

We recently developed a fully electric LNG plant with nine 75-MW electric motors guaranteeing the costumer approximately 14 MTPA with a record availability of 99.8%. Focusing on optimized plant availability, we developed, validated, and patented an advanced torsional vibration control system (TVCS) that can avoid machine trip, minimize commissioning and start-up time, and give real-time insight on torsional phenomena. We can provide integrated monitoring and diagnostic architecture to enable around-the-clock, real-time monitoring, advisory and troubleshooting support through our iCenters. We also offer consolidated expertise on grid stability and load-flow analysis for expansion of power systems, and to help optimize existing systems.

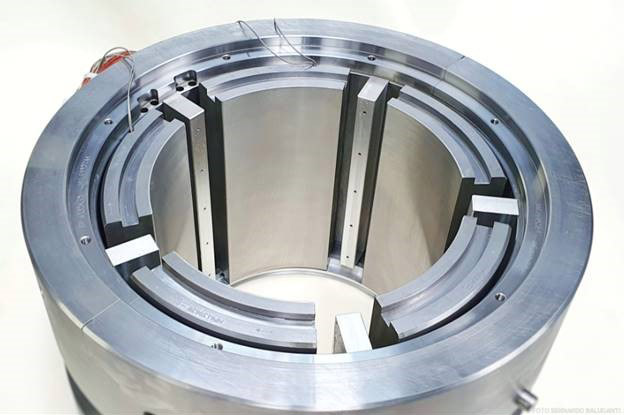

In-house bearing technology

Extreme operating conditions make an integrated bearing plus rotor design more and more necessary. We have therefore developed our own line of bearings with optimal oil consumption in high-speed and high-load conditions (up to 120 m/s, 4.0 MPa) drawing on our Lufkin-RMT Ultra technology for journal and thrust bearings. We're investing in testing facilities, partnerships with universities, and using advanced 3D numerical models to validate our bearings performance and predictability. Our in-house manufacturing technologies have the capacity to produce thousands of bearings per year—including tilting pad and fixed geometry journal bearings, thrust bearings, and combined journal-thrust bearings—ensuring a reliable single source for all orders and after-market service needs.