Highlights

Highlights

Benefits

- Real-time: Provides information on time & location of breach, and location of annular water

- Simplifies data management, providing real-time information on sheath breach, time and location of breach, and location of annular water

Features

- Determine the location and extent of an outer sheath breach

- Portable testing unit with zero equipment footprint

- Utilizes existing, electrically insulated, tensile wire as conductor with no loss of tensile capacity

Applications

- Flexibility for inspection services or continual monitoring system

- Cloud based software with real time annulus condition

- Qualified to 3.64 km riser to flowline with detection modelled to at least 7 km in >4 pipe sections

SPIRE™ Monitoring and Inspection Technology

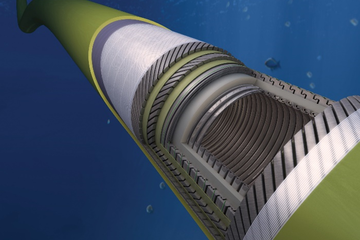

Outer sheath breaches and subsequent annulus flooding are the most significant concerns in the management of flexible pipes. Industry feedback has consistently identified that water accumulation within the annulus is the most common integrity concern for flexible pipes. This can occur from condensed H²O or outer sheath damage which can limit opportunities for later field life extension. The SPIRE™ technology is a flooded annulus detection system that offers a simple and cost-effective solution to the management of critical integrity issues. It provides visibility of water accumulation in real time and valuable insight into the location, extent of flooding and the type of water accumulation.

Engineering Principle

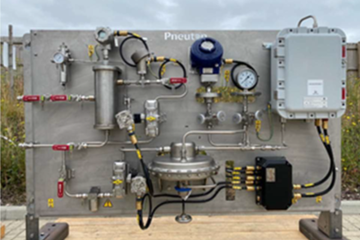

The technology uses low energy electrical signals, directed through an isolated tensile armouring wire to create an electrical signature. Water in the annulus results in changes to the electrical signature which makes it possible to detect the presence of water over distances of 9 kilometers. During the manufacturing phase Baker Hughes flexible pipes can be optionally SPIRE™ enabled for later activation. The electrically isolated tensile armour is terminated within the end fitting assembly using a SmartBolt™ connector. The SmartBolt™ can be connected to either a continuous or portable monitoring unit which allows for water accumulation to be monitored on a continuous basis or intermittently as part of a routine inspection.