Short on inspection capacity? Our global network has you covered.

Access the latest premium NDT X-ray and CT inspection technology at our worldwide Customer Solutions Center locations with flexible, cost-effective CT scans, 3D analysis, and metrology.

No proper in-house CT system for sample size or other criteria?

Use our inspection scanning services at any one of our global CSCs to ensure the safety, quality, integrity, and consistency of your parts and products.

Constrained inspection capacity and/or urgent spikes in volume?

We are available whether you need to inspect a single sample part or a large volume batch. Let our experts with decades of inspection experience help you see things from a new perspective.

Challenges we help solve

NO IN-HOUSE CT SYSTEM?

NO PROPER IN-HOUSE CT SYSTEM FOR SAMPLE SIZE OR OTHER CRITERIA?

CONSTRAINED INSPECTION CAPACITY AND/OR URGENT SPIKES IN VOLUME?

DIFFICULT OR UNIQUE INSPECTION CHALLENGES?

NDT X-ray inspection services that meets your needs

Flexible NDT X-ray solutions

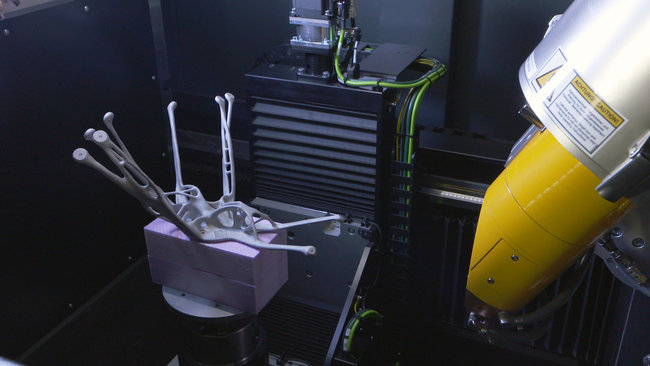

As part of Baker Hughes, we provide flexible radiographic inspection solutions when you need them most. Whether you lack an in-house CT system, have samples that exceed your current system's capabilities, or face unexpected volume spikes, our advanced NDT X-ray and gamma-ray services ensure continuous inspection coverage. Our cutting-edge radiography technology handles specimens of all sizes and complexities, eliminating the need for costly equipment investments.

On demand services

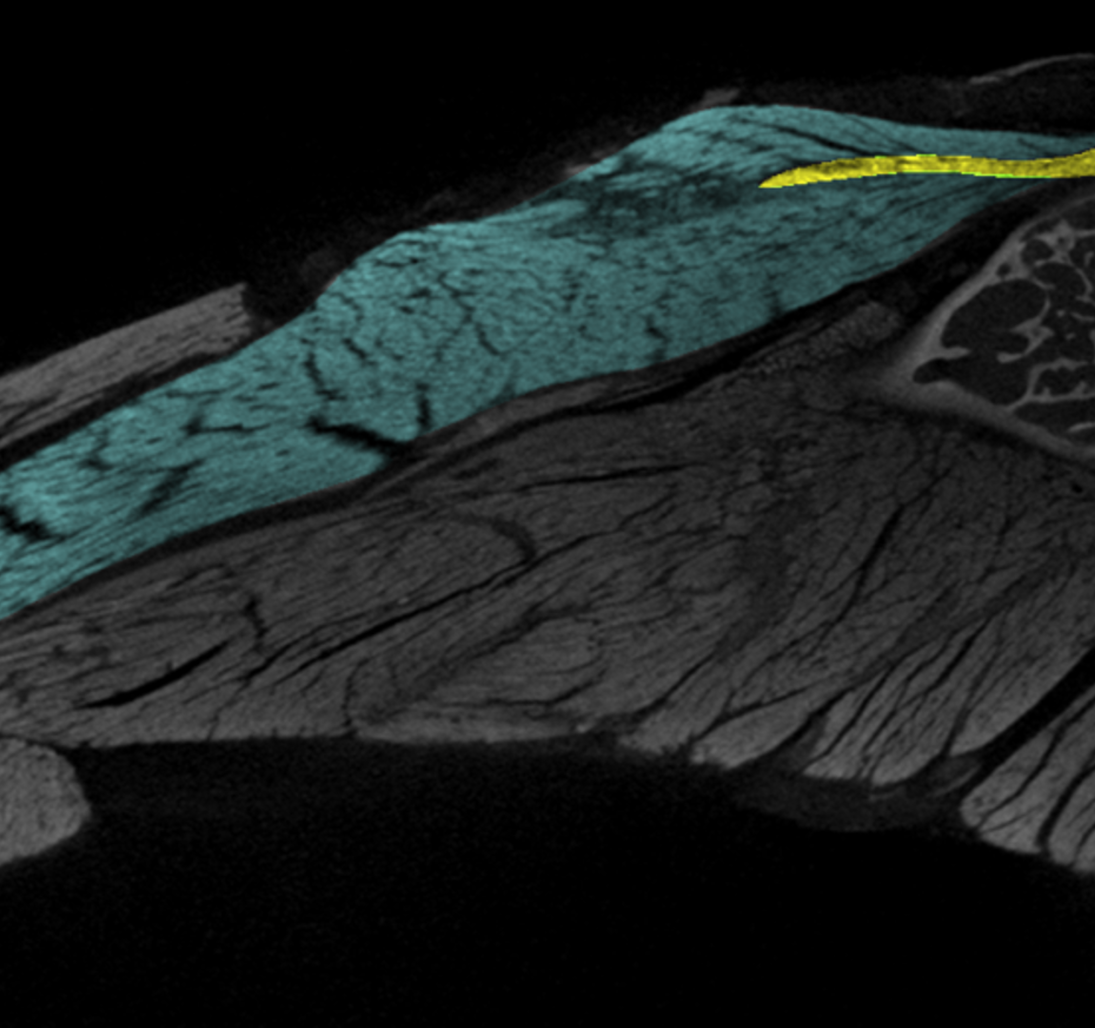

At our global Customer Solution Centers (CSCs), we deliver comprehensive on-demand inspection services powered by Waygate Technologies' cutting-edge NDT equipment. Our offerings include advanced tools for Remote Visual Inspection (RVI), Ultrasound, 2D X-ray, and 3D Computed Tomography, enabling precise failure analysis and dimensional metrology. Need flexible inspection services with state-of-the-art NDT equipment? Whether it's for hourly requirements or project-based work, our CSCs stand ready to serve you with on-demand solutions at any of our global locations.

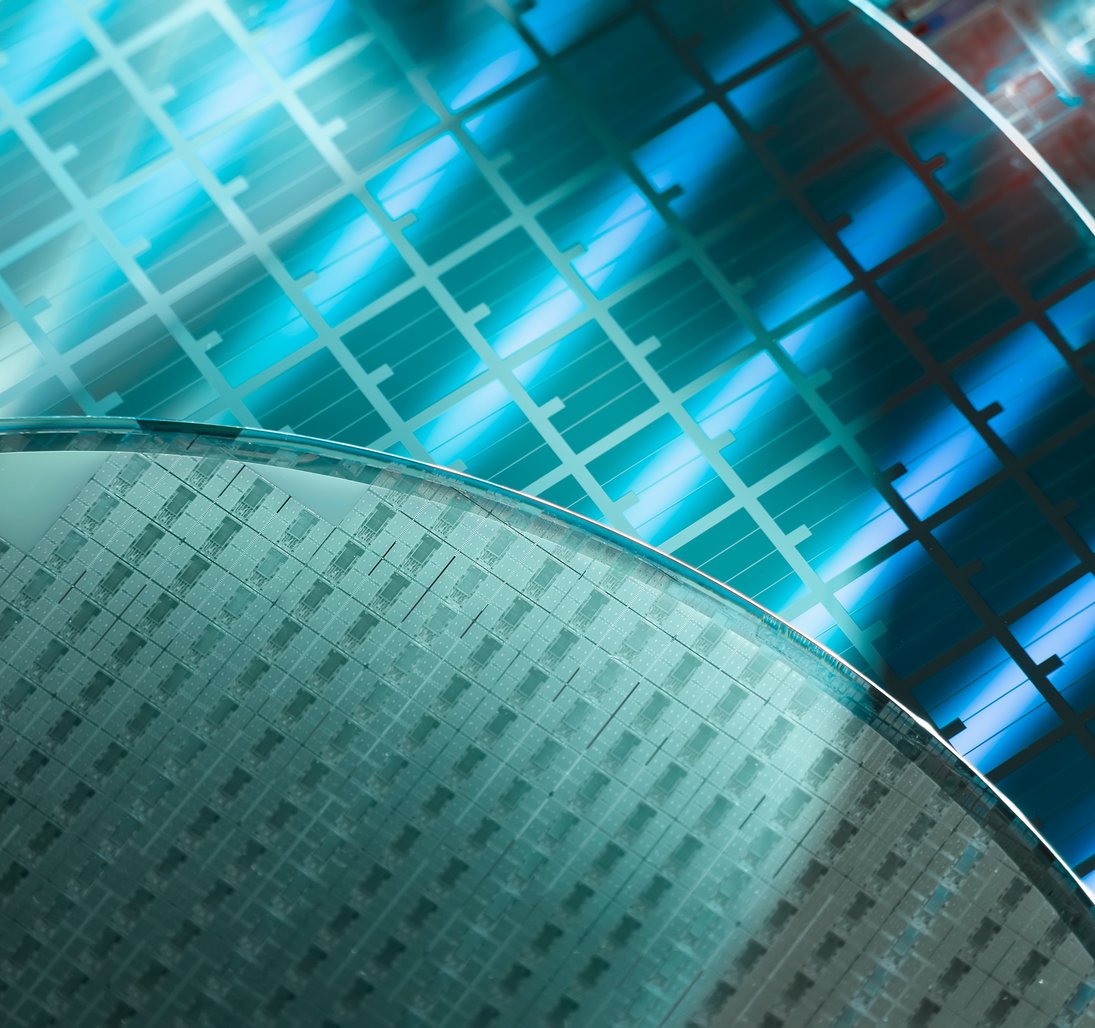

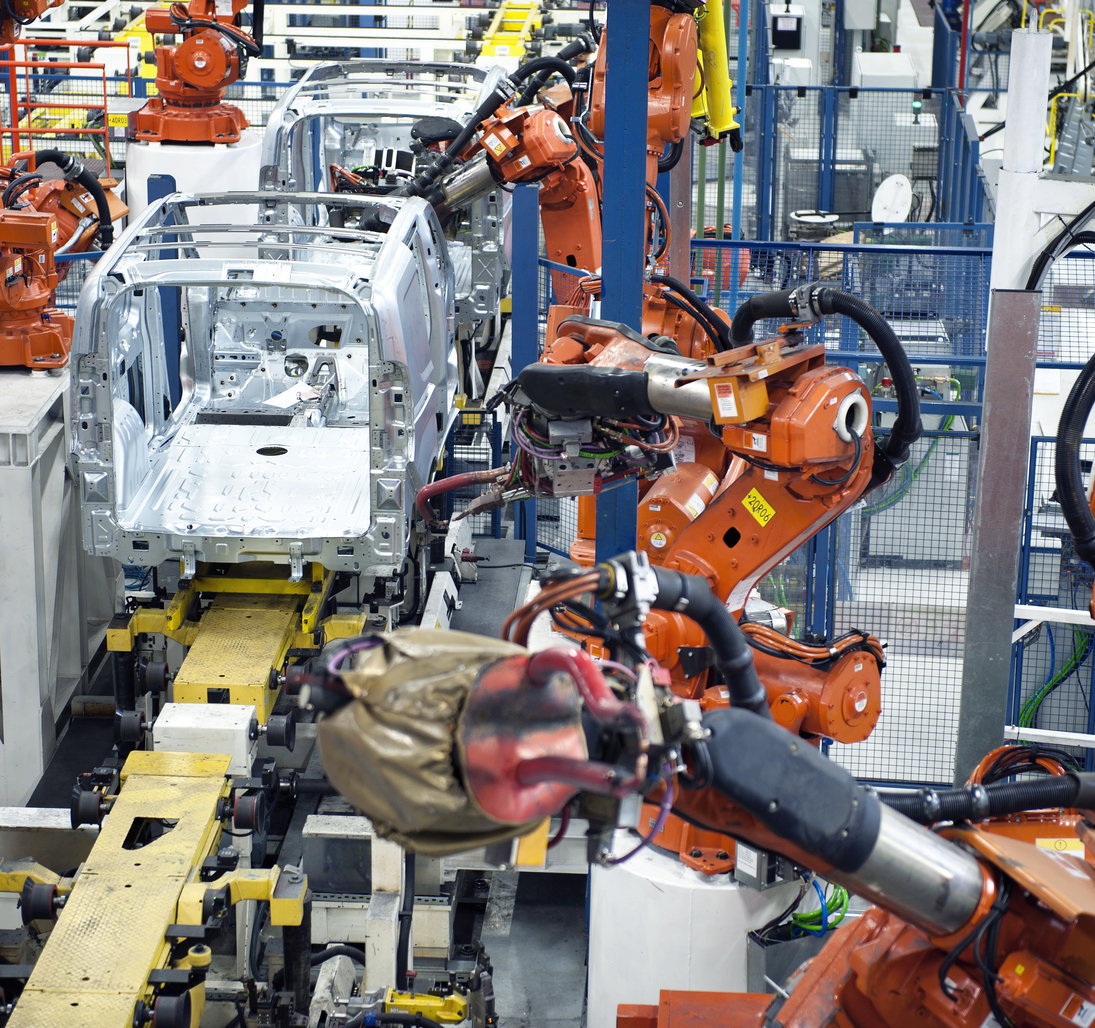

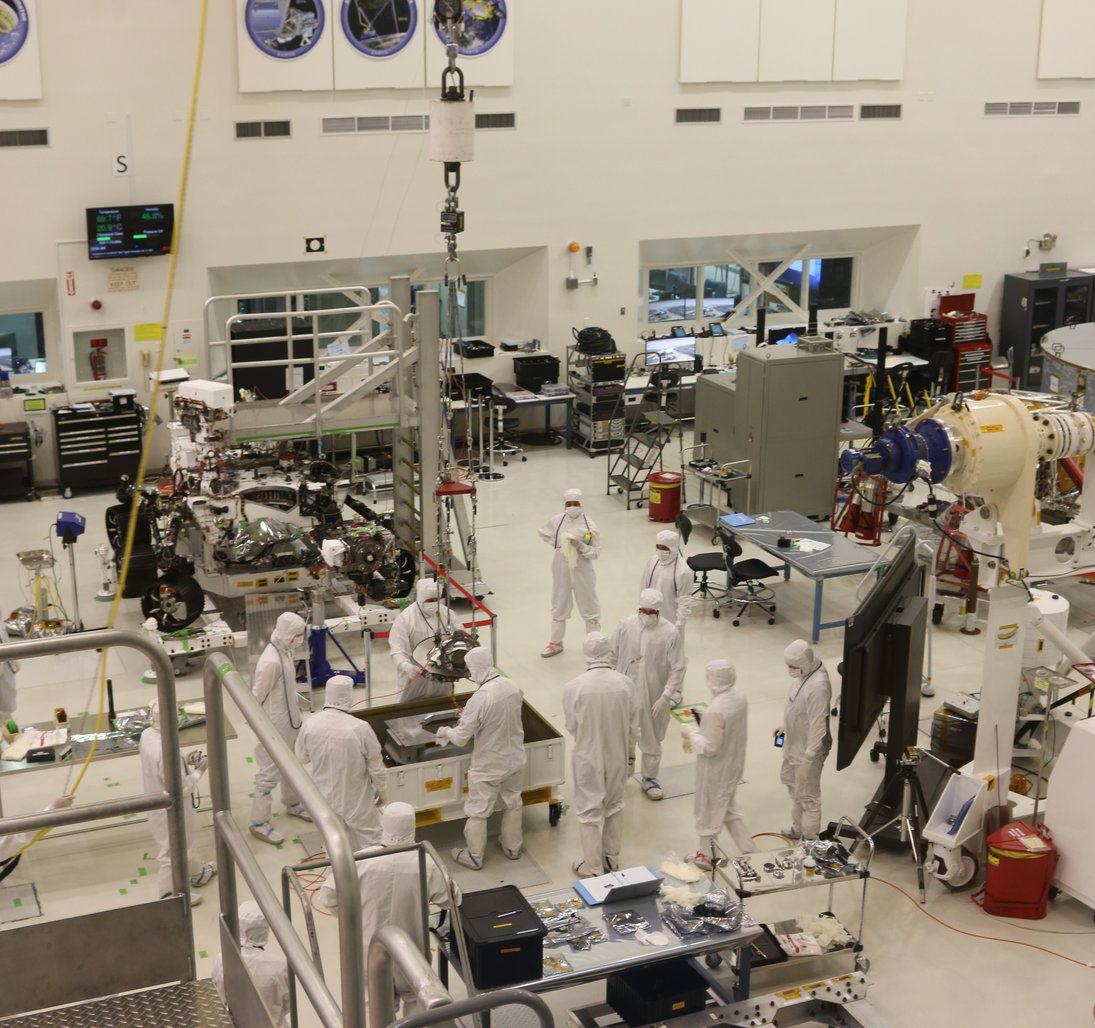

X-ray NDT for every industry

Why choose Waygate Technologies

Unrivalled NDT expertise

With over 120 years of experience in NDT inspection solutions, Waygate Technologies stands at the forefront of innovation. Our diverse client portfolio spans aerospace, automotive, and gas industries, while our pioneering 2D and 3D scanning technology delivers unparalleled accuracy and reliability.

Global solutions, local support

Through our worldwide network of Customer Solutions Centers, we deliver comprehensive end-to-end NDT Xray solutions including equipment, consultation, training, and technical support—ensuring you have local access to our complete expertise wherever you operate.

CSC Munich

Location:

Waygate Technologies

Customer Solutions Center

Schleißheimer Straße 92

85748 Garching bei München

Germany

Telephone: +49 89 45672656

Email: csc.muenchen@bakerhughes.com

CSC Cincinnati

Link: https://www.bakerhughes.com/waygate-technologies/customer-solutions-centers/cincinnati-usa-csc

Location:

Waygate Technologies USA LP

Customer Solutions Center Cincinnati

11988 Tramway Drive

Cincinnati Ohio 45039

United States

Telephone: +1 513 498-3070

Email: csc.cincinnati@bakerhughes.com and tyler.ripperger@bakerhughes.com

CSC China

Location:

1st Floor, Block C, NO.388 Fu Quan North Road, Chang Ning District, Shanghai 200336, China

CSC South Korea

Location:

1F, Building B, Global R&D Center 22, Daewangpangyo-ro 712 Beon-Gil, Bundang-gu, Seongnam-si, Gyeonggi-do, South Korea

Email: inspection.korea@bakerhughes.com

Phone: 031-620-1890

A Level 1 Inspection Service Technique is used when the requirements are the following:

- Scan Only

- Providing raw data only to the customer

- No evaluation, measurements, judgements, communications about the scan characteristics or recommendations are provided to the customer

A Level 2 Inspection Service Technique is used when the requirements are the following:

- Conforming or non-conforming to CT drawing requirements

- Submittal of Certificate of Conformance

- Customer defined inspection criteria

- Any customer requested measurement, evaluation, consulting or exchange of information about the scanned data

- Inspect a single sample part

- Inspect small/special series products

- Inspect a large volume batch

- Complete a specific project

- Access the latest premium X-ray and CT inspection technology on-demand at our worldwide Customer Solutions Center (CSC) locations with flexible, cost-effective CT scans, 3D analysis and metrology. We are available whether you need to inspect a single sample part or a large volume batch to meet production line output demands

- Improve existing processes

- Improve productivity + reliability

- Support set-up of new process

- Accelerate product development process and quality assurance

With our customer training you can enhance your inspection expertise across all levels with our certified RT instructors. Our comprehensive training covers advanced techniques for image enhancement, quality assurance, and protocol optimization, tailored to maximize productivity and output gains. From mastering radiography and CT fundamentals to understanding CT system operation intricacies, our courses empower you with the skills and knowledge needed to excel in the field of inspection.

- Standard trainings

- Specialized or customized trainings:

–software programming or visualization, system, application, or component specific - Recertification or continuing education credits

Radiography is a non-destructive testing (NDT) method that uses penetrating radiation (typically X-rays or gamma rays) to examine the internal structure of materials and components. The radiation passes through the test object and creates an image on radiographic film or digital detector, revealing internal features like:

• Voids, cracks, and porosity

• Inclusions and material variations

• Weld defects

• Assembly errors

• Wall thickness variations

The process is similar to medical X-rays but typically uses higher energy radiation for industrial applications. The darkness variations in the resulting image indicate differences in material density or thickness, allowing inspectors to identify defects without damaging the test piece.