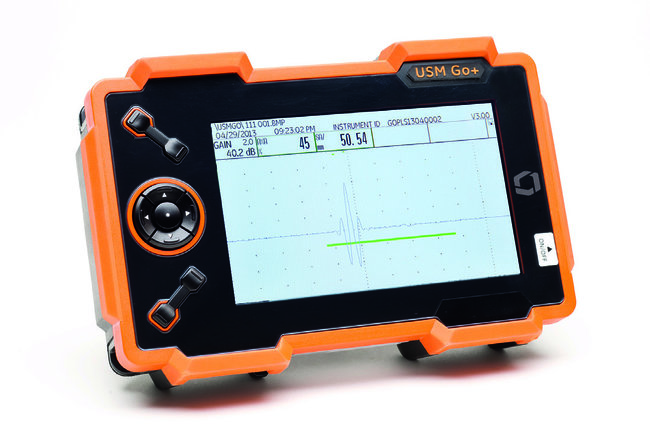

The ultra-portable, ultra-powerful thickness gauge

Featuring intuitive, easy-to-use arrow-keypad control, powerful data management and the latest industrial electronics to provide accurate, reliable and comprehensive thickness inspection data. The Krautkrämer DMS Go+ thickness gauge that can be easily converted into a comprehensive flaw detector with a simple software upgrade

The DMS Go+ Series of A-scan thickness gauges provides accurate, reliable, and comprehensive thickness inspection data in a wide range of applications and environments. All three models - DMS Go+ Basic, DMS Go+, and DMS Go+ Advanced - feature intuitive, easy-to-use arrow-keypad control and carry out from simple A-scan verification to B-scan and full Data Recording. The three thickness gauges are easy to upgrade with additional features and capabilities in order to form a powerful and flexible NDT inspection tool that meets your corrosion thickness application needs. The DMS Go+ Series uses the same operating platform and hardware as the state-of-the-art USM Go+ portable flaw detector. This offers the ability to have an A-scan thickness gauge and full-fledged flaw detector in one powerful & flexible instrument.

Highlights

Highlights

Flexible Performance

- Ergonomic design for easy operation

- High-performance thickness measurement

- High capacity data recorder and compatibility with powerful data management systems

- High capacity data recorder and compatibility with powerful data management systems

- Intuitive arrow-keypad for positive digital control of parameters

- A “Flip” function allows use by both left-handed and right-handed operators

- Portrait or landscape views to match user preference

- Large display screen ergonomically sized to reduce eyestrain, which can be adjusted to provide optimum visibility in various ambient light conditions

- Small size, lightweight (870g, 1.9lb), robust construction to IP67 for operation in harsh environments

- Automatic gain control for excellent repeatability and corrosion monitoring

Cutting-Edge Technology

- Built-in temperature compensation for accurate measurement up to 540°C (1000°F)

- Save and load parameter sets for easy recall and repeatability from inspection to inspection

- On-board data recorder, with the capacity for thousands of thickness readings, with storage of A-scan, B-scan and MicroGrid attachments

- Expanded data recording capability with additional boiler, custom grid, custom linear, custom point, and 3D, & 4D file structures via UltraMATE

- Data transfer via SD card or USB port. Data can be transferred in various file formats to allow easy integration with user data management system

- Export data in multiple file formats (e.g. CSV, PDF, DAT, XML, JPG screen capture)

- Compatible with many of the popular mechanical integrity risk-based inspection data management analysis programs.

Applications

- Inspection and monitoring of corrosion in tubes, vessels, and tanks

- Measurement of remaining wall thickness through paint coatings

- Inspection of complex geometry tubes

- Monitoring of boiler efficiency by measuring oxide scale in boiler tubes with special probe OSS-10

- Maintenance checks

- Thickness measurement of austenitic materials

Provides accurate, reliable thickness inspection data on metal devoid of coatings.

Provides a DUAL MULTI operating mode for measuring the thickness of metal through coatings.

Provides a DUAL MULTI operating mode for measuring thickness over coatings just like the DMS Go+ while adding a data logger feature.