Waygate's line of Krautkramer ultrasonic contact transducers and probes are built to last, easy to use and most of all, one of the most accurate ultrasonic testing tools on the market. This means you get better results, every time. We offer many different types of contact probes including multiple straight beam single element, straight beam dual element and angle beam options.

- Straight Beam Single Element Probes

- Straight Beam Dual Element Probes

- Angle Beam Probes

We used to be GE Inspection Technologies, now we’re Waygate Technologies, a global leader in NDT solutions with more than 125 years of experience in ensuring quality, safety and productivity.

Phased array ultrasonic testing that meets your needs

As the world leader in NDT, we believe a name is only as meaningful as the results it delivers.

Waygate Technologies delivers comprehensive phased array NDT solutions for every inspection challenge. Our diverse probe range supports both standard and specialized testing needs across industries.

From material assessment and weld integrity to corrosion monitoring and composite analysis, our advanced portfolio includes capabilities for immersion testing, thin plate examination, and bolt inspection. We provide the precise technology you need, backed by our commitment to innovation.

Typically used for manual inspections, straight beam single element transducers are ideal for scanning parts with regular geometry and relatively smooth contact surfaces. This includes flat or curved surfaces where you need to identify flaws or a backwall parallel to the surface or detect with a beam normal to the surface. With improved near surface resolution, you can use these probes along with a couplant layer (typically gel, oil, or paste) when you need to penetrate a thick section of material.

Straight beam dual element (TR) transducers are best for manually scanning thin sections of material when looking for flaws or backwalls parallel to or those which are detectable with a beam normal to the surface. With excellent near surface resolution and reduced noise caused by scattering, these probes transmit and receive elements separated by a crosstalk barrier. They can be contoured and coupled on curved and rough parts and surfaces and do require a couplant layer, typically a gel, oil or paste.

For European Customers: Probe models have side mounted Lemo 00 connectors, side mounted Microdot SEB..KF types

For North American Customers: Probe models use fixed BNC cable (ADP) or side mounted MMD (FDU)

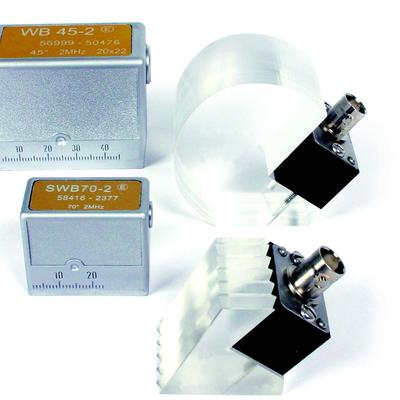

Angle beam probes are preferred for parts with inclined flaws, such as welds, and are sometimes used in mechanized or automated testing. They use refraction to transmit shear or longitudinal waves at a predetermined angle, while most standard transducers generate shear waves by mode conversion. Elements are mounted on integral or replaceable wedges, requiring a couplant layer, typically a gel, oil or paste.

Our angle beam probes are available in both single and dual element types, and in multiple sizes.

A lot of our most popular standard probe types are available in North America for online purchase and immediate shipment. See what's available.