What are the basic methods of ultrasonic testing?

Sound is a phenomenon which does not cause any permanent change although its transient presence is very noticeable. This is why " sound" (with low energy) is so suited for nondestructive testing i. e. the airn is to obtain exact information on the condition of the specimen being tested. For this purpose a method is required which produces a clear reaction within the specimen but does not change its condition. "Being passive" is, therefore, the most eminent feature of sound which is required for testing materials.

In the special area of acoustic emission passive sound is used as well whereby the sound waves are generated inside the material by spontaneous changes in the condition of the material. Sound waves are mechanical waves and thus require a medium which functions as a carrier. Each material whether solid, fluid or gaseous can be evalutated through the special effects on the sound waves. The entire ultrasonic test ist based on how sound waves are influenced when they propagate within the medium being tested. The sound wave undergoes changes which can be measured and according to which the condition of the material can be evaluated. The evaluation of the properties of a material can then only follow indirectly. By means of models and empirical correlati ships one can interpret certain changes in the sonic signal as a change in the structure of the material or the existence of an inclusion etc. The evaluation of the quality of,a material always depends upon the reliability of th concept regarding the interpretai of the signal.

The interference to the propagation of sound which is used for evaluating materials is always based on the same principles:

2.1 interference due to an Interface. For example due to the limiting faces of the test specimen or by macroscopic interfaces such as cracks am microscopic interfaces such as grab n boundaries.

2.2 interference due to absorption. This is substantially a transformation of energy produce by internal friction. The evaluation in this case is done by the changed signal passing through the medium or by that signal reflected at an interface.

These fundamental effects of interference have resulted in different ultrasonic testing methods and they are:

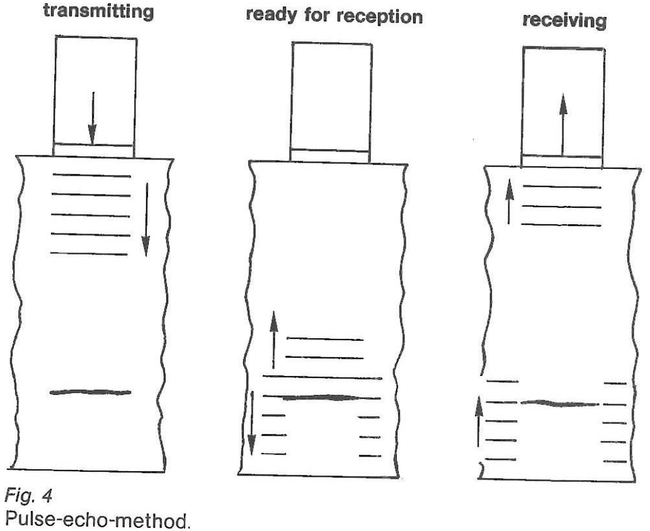

2.3 Resonance method Here use is made of the reflection between two parallel limiting faces of the test specimen (fig. 1).

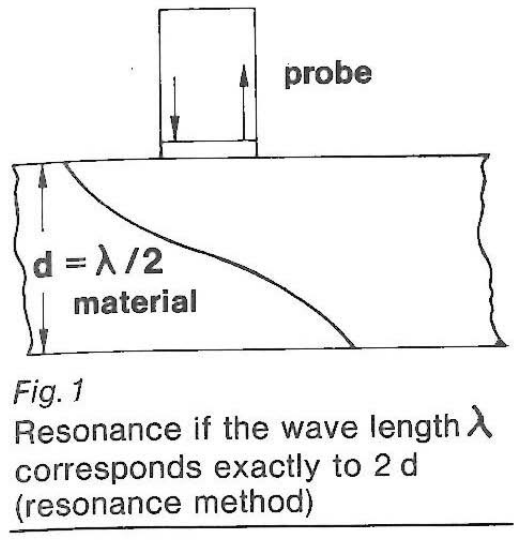

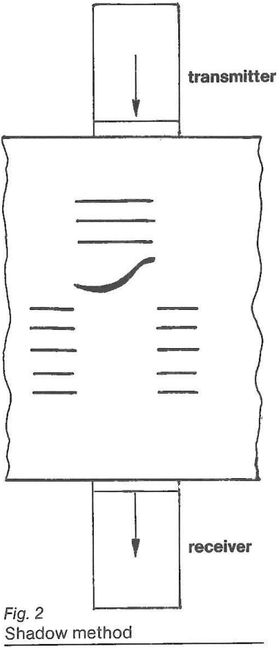

2.4 Through-transmission method which, as in other languages, could have been better referred to as the " shadow method". In this method the shadowing effect of a material interface ( material discontinuity) is used. Two opposing probes can be used (fig. 2) as can the " mirror-shadow-method" with the probes on one side of the test specimen (fig. 3).

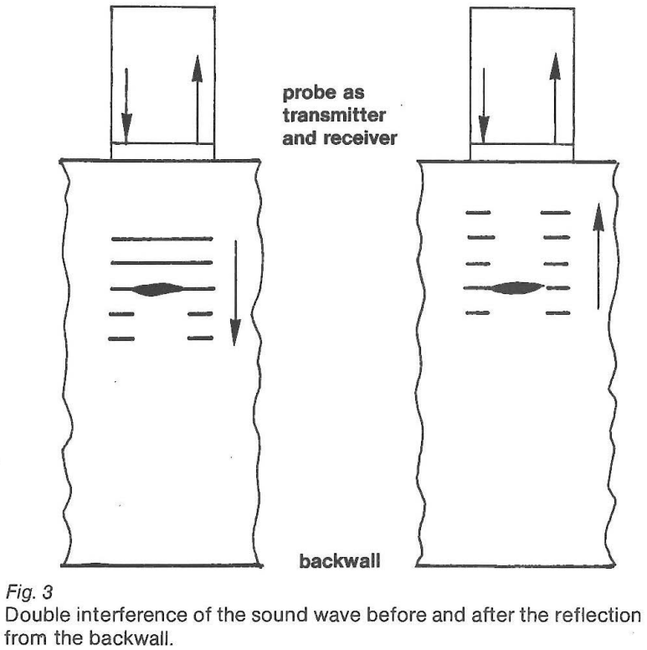

2.5 Echo method. This method uses the signal which is reflected from a discontinuity in the material (fig. 4). Here the transmitter probe can be identical to the receiving probe, separate transmitter and receiver probes can also be used.

The most important of all the echo methods and at the same time of all the ultrasonic testing methods, is the pulse-echo-method. By using ultrasonic pulses not only the size of the reflection indication (echo amplitude) can be evaluated — the echo transit time can be evaluated too. Thus oneobtains data not only of the size of the reflector but also data regarding its position. If the position of the reflector is known (back well) then, by using the transit time, the structure of the material can be evaluated. If the location of the reflector is not known but the properties of the material are (attenuation, sound velocity) then e. g. well thickness measurements can be carried out.