Phased Array Probes

We manufacture a wide variety of reliable phased array ultrasonic testing probes and transducers for many applications. Our portfolio of over 600 phased array probes options combines decades of expertise with cutting-edge innovation, delivering unmatched precision in material testing.

One Probe Multiple Inspections

Eliminate the need for multiple probes and repeated scans with our versatile phased array technology. Our advanced fixed angle and focus options enable comprehensive inspections from a single setup, while immersion and delay line probes efficiently cover larger areas in less time, maximizing your operational efficiency.

Product pairing for better phased array ultrasonic testing

Experience the power of intelligent probe design with our Dialog feature. When connected to Mentor UT, these smart probes automatically configure your system, and download transducer information straight to the device. This seamless integration ensures you spend less time on setup and more time on inspection.

Phased array ultrasonic testing that meets your needs

As the world leader in NDT, we believe a name is only as meaningful as the results it delivers.

Waygate Technologies delivers comprehensive phased array NDT solutions for every inspection challenge. Our diverse probe range supports both standard and specialized testing needs across industries.

From material assessment and weld integrity to corrosion monitoring and composite analysis, our advanced portfolio includes capabilities for immersion testing, thin plate examination, and bolt inspection. We provide the precise technology you need, backed by our commitment to innovation.

Discover our diverse range of phased array probes

Weld Inspection Probes

We offer a range of weld inspection probes, including small footprint weld probes and integral wedge probes. The small contact area on our small footprint probes fits on standard single element MSWS wedges—comparable to standard single element MSWS probes with phased array capabilities.

And our integral wedge probes are durable and ergonomically designed with a die-cast housing, similar to conventional probes—allowing for easy transfer from conventional to phased array inspection with existing mechanics and probe holders that can be reused.

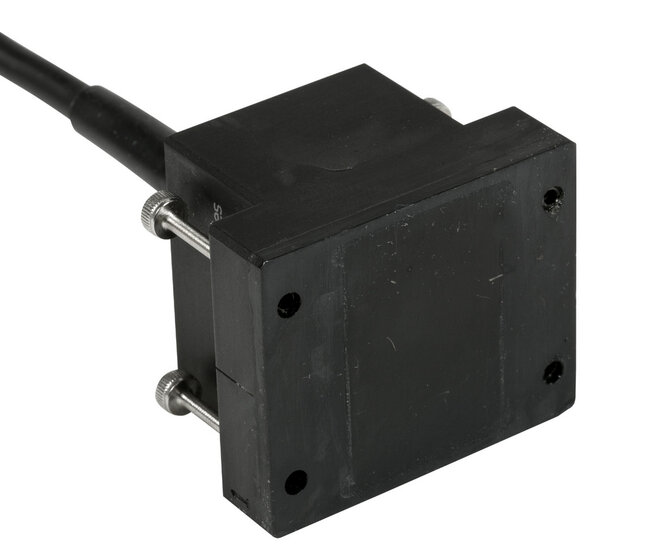

Bolt Inspection Probes

Our bolt inspection probes are a best choice to yield high-quality results and strong PoD for the detection of defective areas in threaded bolts. This is crucial to reducing construction failures and potential liabilities. The protective membrane enables steady coupling on rough surfaces, and they come available with multiple connector types.

Phased array ultrasonic testing for all industry needs

Automotive

Inspection & NDT solutions for the automotive industry

Why choose Waygate Technologies

With decades of specialized experience and cutting-edge NDT technology, we deliver trusted inspection solutions across diverse industries and applications. Our team of certified experts provides comprehensive testing services that ensure safety, reliability, and compliance across all industries.

Power Generation

We support critical infrastructure inspection needs with specialized solutions for general weld examination, austenitic weld testing, and comprehensive inspection of pressure vessels, piping systems, turbine blades, and rotors.

Oil and Gas

Our advanced NDT capabilities ensure asset integrity through precise pipeline girth weld inspection, tank examination, and general weld testing, maintaining the highest safety standards in challenging environments.

Aerospace

Meeting the industry's stringent quality requirements, our solutions excel in specialized weld inspection, gear testing, and advanced composite material examination, detecting delamination and disbands with unprecedented accuracy.

Automotive

We provide reliable testing for critical components including axles, shafts, spindles, brake discs, and wheels, ensuring both safety and production efficiency in high-volume manufacturing environments.

General Manufacturing

Our versatile technology supports diverse applications including weld verification, forging and casting inspection, plate and bar testing, tubular goods examination, in-line thickness measurement, and structural integrity assessment of bridges and buildings.

Our products success stories

A lot of our most popular standard probe types are available in North America for online purchase and immediate shipment. See what's available.

Phased array ultrasonic testing (PAUT) is an advanced non-destructive testing method used to inspect materials and components for flaws or defects.

The basic principle involves using multiple ultrasonic elements (typically 16 to 256) arranged in a single probe. These elements can be electronically controlled to:

- Fire in a specific sequence (with precise timing delays)

- Create focused and steered ultrasonic beams

- Generate different beam angles and focal distances

Key advantages of PAUT over conventional ultrasonic testing:

- Better coverage and inspection speed, as it can examine materials from multiple angles in a single scan

- Improved detection of defects, especially in complex geometries

- Enhanced visualization through sectorial scans (S-scans) and other advanced imaging capabilities

- Digital data recording for better documentation and analysis

- Reduced inspection time compared to conventional methods

Common applications include:

- Weld inspection in pipelines and pressure vessels

- Aerospace component testing

- Power generation equipment inspection

- Composite material evaluation

- Corrosion mapping in metal structures

A phased array ultrasound transducer is a sophisticated probe containing multiple ultrasonic elements that work together to inspect materials and detect flaws. It is as a high-tech scanning device with many tiny sensors (usually 16-256 elements) that can be controlled independently.

These transducers help:

- Steer and focus ultrasonic beams electronically

- Create different scanning angles without moving the probe

- Provide detailed images of the material being tested

- Offer better coverage than traditional single-element probes

Transducers work by precisely timing the firing of each element, similar to a wave. This coordination allows the probe to:

- Focus sound waves at specific depths

- Create various beam shapes

- Generate clear images of the inspected area

- Detect defects from multiple angles

Common types include linear arrays (elements in a straight line), 2D matrix arrays (elements in a grid), and curved arrays (elements on a curved surface). These transducers are widely used in industrial inspections and quality control testing.

For a convex phased array transducer, the typical value for electrical signal delays falls within the range of 0 to 10 microseconds (μs), with delay increments typically in the 2-4 nanosecond (ns) range for precise beam forming and steering control.

Other services

NDT software

Industrial ultrasonic testing

Robotic inspection