Ultrasonic thickness solutions for any application

Ultrasonic Thickness Gauges are valuable tools designed to improve safety and ensure the reliability of equipment and materials subject to corrosion or erosion. Choosing the right gauge depends on the specific application and desired level of precision.

For corrosion inspection, the Krautkrämer DMS Go+ and DM5E utilize dual-element transducers to accurately measure remaining wall thickness in components like pipelines, pressure vessels, and storage tanks, crucial for maintaining safety and structural integrity in industries like oil and gas.

Meanwhile, the single-element transducers of the Krautkrämer CL Go+ provide exceptional precision for measuring thin materials and a wide range of metals and non-metals such as glass, ceramics, and plastics. This makes it ideal for applications requiring highly precise measurements, such as in the automotive, aerospace, and manufacturing sectors.

Selecting the correct probe is essential for optimal results. Factors such as material type, geometry, thickness range, required accuracy, surface condition, and operating temperature all influence probe choice. We offer a wide range of probes designed for:

• Standard applications

• Thin or thick wall components

• Complex geometries

• Precision thickness measurements

• High sound attenuation materials

• High-temperature components

Specialized application probes are also available upon request. With our diverse selection of instruments and probes, we can provide the ideal solution for your specific thickness measurement needs.

An ultrasonic thickness gauge is a device used to accurately measure the thickness of a given material, typically steel, plastic, alloys, and the like.

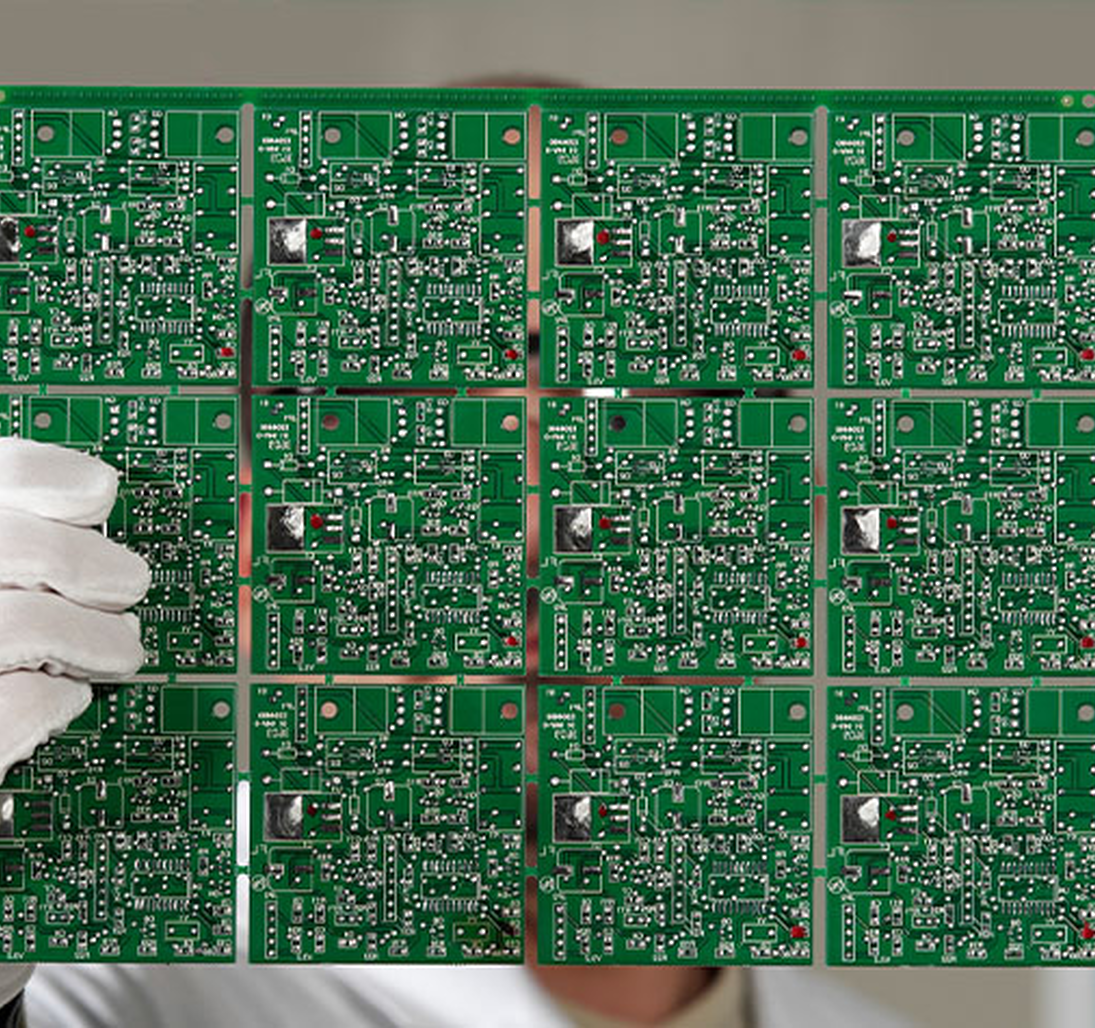

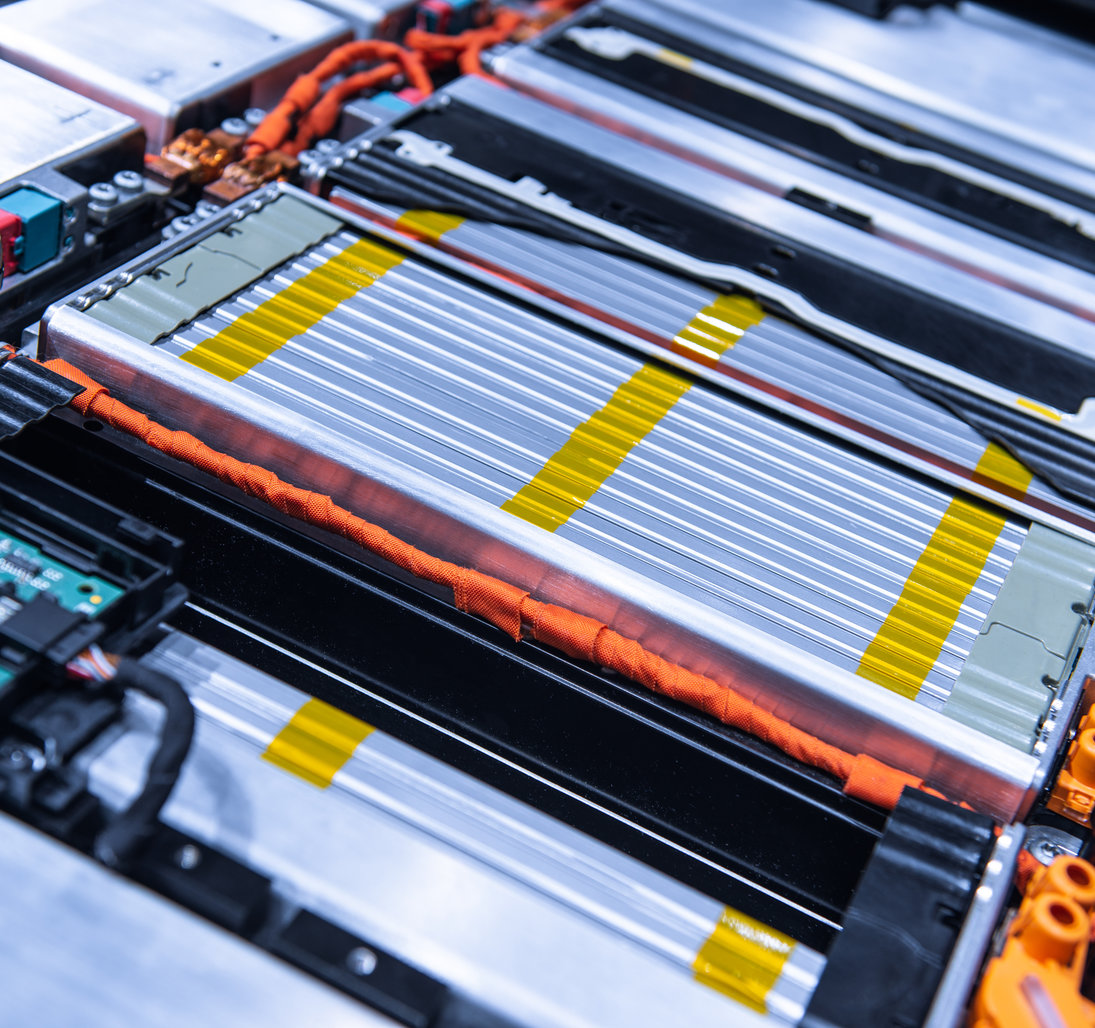

UT thickness gauges are deployed in many industries but are most commonly used in Automotive, Aerospace, and Manufacturing to help ensure material thickness complies with production standards and their given industry's regulations.

UT thickness gauges can also be used as an additional quality assurance tool that helps to identify corrosion - particularly useful in the Oil & Gas industry where pipeline integrity is a concern.

Some models allow for the measurement of material through the exterior painted surface - thus removing the need for paint removal prior to measurement.

- Non-destructive testing (NDT) protocol means you don't have to sacrifice production samples

- Measurements can be taken without requiring access to both sides of the target material

- UT thickness gauges can measure through coatings

- A high degree of accuracy, typically around ~0.1 mm

- Perfectly suited to in-field testing, some models are rated for hazardous environments

- Relatively inexpensive to own and operate

- Some devices do not require the use of a couplant

- Typically requires a separate calibration for each material being tested

- Accurate readings require good contact with the target material

- Some devices cannot take accurate measurements in the presence of surface rust

- Some devices require a coupling material between the target material and the probe

- Some level of technical expertise required to interpret results

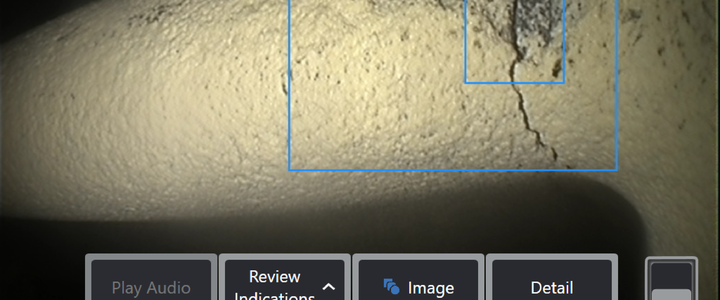

Ultrasonic thickness gauges are ideally suited for the inspection of material structures such as metals, ceramics, plastics, and composites. Industrial applications include:

While there are several methods of calibration, such as One-point, Two-point, Auto or Manual On-block and Off-block Zero, Automatic V-Path correction, the underlying principle is that you will typically need to calibrate your device every time you switch your target material.

When using NDT equipment such as an ultrasonic thickness gauge, calibrations are performed via calibration blocks, also known as test blocks, that serve as a reference standard for a given target material.

Additionally, different calibration blocks can simulate different conditions, allowing the operator to calibrate for both the target material and conditional factors.

Some questions to consider when selecting the right ultrasonic thickness gauge for your application include:

- What factor (thickness, flaw detection, corrosion, erosion, etc.) am I testing for?

- What target materials do I need to be able to test for?

- Does my team require additional, specialized training to operate this equipment?

- What accessories (i.e. transducers, probes, couplant, calibration blocks, cases, etc.) are required? How much do they cost?

- What production and industrial standards am I testing to, and can the equipment test to those standards?

If you're unsure what device is best suited to your specific NDT needs, why not contact us and one of our UT experts will be happy to assist you.

While there are several resources available for non-destructive testing (NDT) training, Waygate Technologies offers NDT training across the broadest range of inspection methods, which are offered around the globe, or at a location of your choice.

Get your team up to speed on how to most effectively use their ultrasonic thickness gauges today!

Our Ultrasonic Thickness Gauge Solutions

Krautkrämer CL Go+ Precision Thickness Gauge

Micro-meter precision in a rugged package. With its intuitive menus and easy-to-use switch pad control, users can focus to make best use of the various features of the Krautkrämer CL Go+. It also boasts powerful data management capabilities, allowing users to store and analyze inspection data with ease.

Unrivaled precision, stability, and repeatability

Ergonomic design: Lightweight, bright and large display

Effortless inspections with intuitive navigation

3-in-1 device: Easily upgradable to a flaw detector, corrosion gauge or both

DMS Go+ Series A-Scan Thickness Gauges

Handheld instruments for thickness measurement, data recording, and data management for a wide range of applications and environments.

- Ergonomic design for easy operation

- High capacity data recorder and compatibility with powerful data management systems

- Intuitive arrow-keypad for positive digital control of parameters

- A “Flip” function allows use by both left-handed and right-handed operators

- Portrait or landscape views to match user preference

- A large 800x480 pixel display screen

- Small size, lightweight (870g, 1.9lb), robust construction to IP67 for operation in harsh environments

- Automatic gain control for excellent repeatability and corrosion monitoring

DM5E Corrosion Thickness Gauges

Rugged, ergonomically designed, easy to use for measurements you can trust. Compatible with our best-in-the-industry probes, their ergonomic design and rugged housing are built to withstand even the harshest environments.

- Easy, intuitive operation takes thickness readings automatically, guiding you through every step

- Dedicated state-of-the-art probes allow for improved high-temperature performance

- DM5E and DM5E DL offer dual-multi measurement, allowing convenient measurement through protective coatings

- DM5E DL includes a built-in data logger supporting up to 50,000 readings