Best Solution for Aircraft Inspections: Borescopes

Aerospace companies are grappling with the need to meet tightening regulations and meet an unprecedented demand for MRO engine services. Inspection managers can’t afford to deliver anything short of flawless inspections to protect the safety of their employees, passengers, and their brand reputation, but they are still pressured to move faster and keep costs down to meet profitability goals. Based on price alone, low cost borescopes from new market entrants are capturing more and more attention.

Waygate Technologies offers two high-quality borescopes—the Mentor Visual iQ+ and Mentor Flex—that can give accurate results, faster. Innovation drives aerospace solutions; quality ensures value is delivered.

Designed to be the go-to video borescope, the Mentor Flex is durable and easy to use. Now, with Real3D measurement, this video borescope is more flexible than ever.

With an upgraded articulation design founded on high-power steering motors, the Everest Mentor Flex allows technicians to effortlessly navigate even the most challenging inspection paths, resulting in less time spent searching and more time spent capturing and analyzing indications — at a fraction of the time and cost. Two and a half times more torque than today’s motors provides an increase of 42% in articulation range. And 16% less friction gives an ultra-responsive feel while extending articulation over the life of the product.

Airplane engines are notably difficult to inspect. Advanced articulation, in combination with our near-focal optical tips, make for faster and easier aircraft maintenance inspections.

Featured

With amazing image quality, this industrial video borescope provides clarity to inspectors to produce more accurate inspections. The combination of precision optics, image processing and transformations, the Mentor Flex increases your probability of detection.

Often during gas turbine inspections, image transforms such as Dark Boost and HDR can provide the extra details required to make the right call for maintenance requirements.

Featured

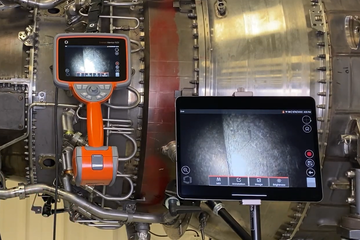

The Mentor Flex provides wireless digital services out of the box from the InspectionWorks platform.

- Plan for repeat inspections by creating a Menu Directed Inspection template

- Automatically backup inspection data to the cloud

- Reporting templates and auto-generation

- Share the video borescope screen, or provide local control to Android, or iOS device

Featured

Point to What You Need

The Everest Mentor Flex’s virtual keyboard enables 300% faster annotation, and its multi-point touchscreen provides pinch-to-zoom as well as swipe and pan gesture functionality. Menu Directed Inspection (MDI) empowers inspectors with auto-image smart tagging and automatic report generation, plus customizable user profiles and an embedded help menu. Last, but certainly not least, InspectionWorks Connect takes inspections to the future with wireless video streaming and file transfer to iOS devices over dual-band Wi-Fi.

Featured

Real3D Stereo Measurement provides accurate and precise defect assessment through the use of a 3D point cloud, with dynamic cursor repositioning.

Featured

Designed with complex inspection applications in mind, the Everest Mentor Visual iQ+ video borescope meets the highest standards in image quality, 3D measurement capability, and workflow automation.

Advanced 3D Inspection Software

Real3D™ measurement combines fully surfaced point cloud visualization, advanced measurement algorithms and an insightful 3D Surface Mask to enable more accurate and repeatable measurement decisions. Choose from Real3D Stereo or 3D Phased Measurement which allows measurement on-demand without changing tips.

Each of these technologies is compatible with some or all measurement types to help get the measurement needed in every application. They include basics like length, depth point to line and area, but also specialty types including missing corner area, area depth profile, automatic blade tip clearance and radius gauge for boro-blending assessment.

Aside from measurement types, Real3D provides advanced tools such as depth assist and measurement plane to further increase accuracy of measurements.

What's New with Measurement?

- Missing Corner: measures the area and edge lengths of a missing blade corner with 1 point designating the tip and up to 23 additional points placed along broken edge. Now inspectors can accurately determine how much material has detached for quick engine serviceability assessment.

- Surface Angle: measures the angle between a reference plane and an angle plane. For the first time on any borescope, we can now determine deformation or deflection of a compressor blade to provide a the value in degrees. Surface angle uses a simple 4 cursor workflow very similar to depth.

- Auto Area: generates masks quickly to calculate an area you specify.

Featured

HD Resolution and 3D Image Stitching

This industrial borescope offers on-demand measurement with the most advanced 3D capabilities, providing more accurate measurement from increased distances. 3D Stitching combines individual images and corresponding point clouds to a larger image which enables measurement of larger defects across multiple images and the ability to accurately locate the position of defects in relation to a fixed point-of-interest. Users can adjust cursor placements in the fully-surfaced Point Cloud to deliver results with confidence.

What's New with 3D Stitching

- 2X Faster: users can leverage the MViQ+'s increased processing power to run more features simultaneously.

- Increased Image Limit to 10: the MViQ+ can now handle composite images consisting of up to 10 images where the original MViQ had a limit fo 5.

- Optimized Algorithms for Improved Point Matching: we are constantly improving our stitching algorithms to give users even more increased performance.

Featured

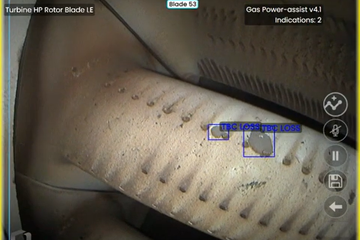

Defect Detection and Blade Counting

Leverage computer vision and machine learning to help improve consistency and reliability of inspection tasks and increase the overall quality of an inspection output. The Mentor Visual iQ+ enables users to leverage analytical models from multiple sources.

- Waygate Technologies analytics Gas Power-assist and Blade Counter developed to improve inspection reliability and data integrity.

- Third Party partner analytics are available directly on the MVIQ+; users can leverage Aiir Innovations’ aviation commercial engine models for defect detection.

- For customers developing their own analytics, the MVIQ+ enables deployment to a global team.

- User Guides are available in the Resources section for each analytic outlining applicability, performance metrics, operating procedures, frequently asked questions, and more.

What's New

With continued focus on robust detection and categorization, Gas Power-assist 5.0 is now available.

- Analytic models updated with additional training images from industry partners to improve performance

- Increase in True Positive Rate and decrease in False Positive rate for a wide variety of gas turbines in aerospace and power applications.

Featured

TrueSight™ Image Software

TrueSight™ provides a blend of high resolution image capturing and processing functions, precision optics and a powerful suite of proprietary image transforms used to enable better visual inspection decisions.

The suite of image transforms is included in the Pro package and available for Start and Enhance.

This POD SW includes the following (click to watch videos): Live 3D Stereo, Adaptive Noise Reduction (ANR), Dark Boost, Distortion Correction, Inverse+, Variable High Dynamic Range (VHDR) and Color Saturation.

Featured

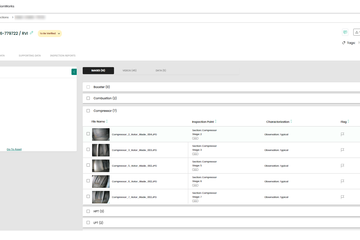

Cloud Connectivity and InspectionWorks

The MVIQ+ comes with InspectionWorks, a secure and scalable cloud-based inspection platform that integrates every component of the nondestructive testing , turning data into useful intelligence for faster and better decisions.

- Make your devices ready Access centralized cloud repository to enable download of MDI, ADR, or media to the device.

- Launch your inspection plan Conduct your inspection using standardized templates powered by MDI (menu directed inspections).

- Centralize your data Effortlessly transfer data for unified access using Push2IW.

- Leverage your AI Access your or our ADR algorithms to analyze and increase processing efficiency.

- Software updates Connect to the network to keep updated with the latest features. You can get started today with your free InspectionWorks account.

Featured

Fully Automated Turning

To enable repeatable image capture of every blade in each stage, the updated protocols let the MViQ+ video borescope and the Rhinestahl FutureDrive NG+ turning tool perform 2-way communication to fully automate turning the engine. Previous time delay image capture can sometimes cause errors and consume unnecessary waiting time between stop and image capture. Now consistent images are provided in less time.

Featured

Small diameter probes are more nimble, making them the go-to for those tight spaces in aircraft inspections. They excel at maneuvering inside tight spaces like the outer air ducts of low pressure turbines.

The 2.2mm and 3.0 mm diameter probes can be interchanged easily with other borescope system probes, making our system the first in the industry to offer true small probe interchangeability.

Featured

Like all of our video borescopes’ interchangeable probes, if damage occurs, we will repair or replace only the damaged probe—a much more cost-effective solution than repairing or replacing an entire fixed probe system.

With our new small diameter probes, you get all of the high-end features you expect from your VideoProbe system, including: – Menu Directed Inspection (MDI) for increased productivity during and after the inspection—with smart data tagging and automatic report generation – InspectionWorks Connect for remote view and control capability from a tablet.