Component Testing and NDT Solutions for the Automotive Industry

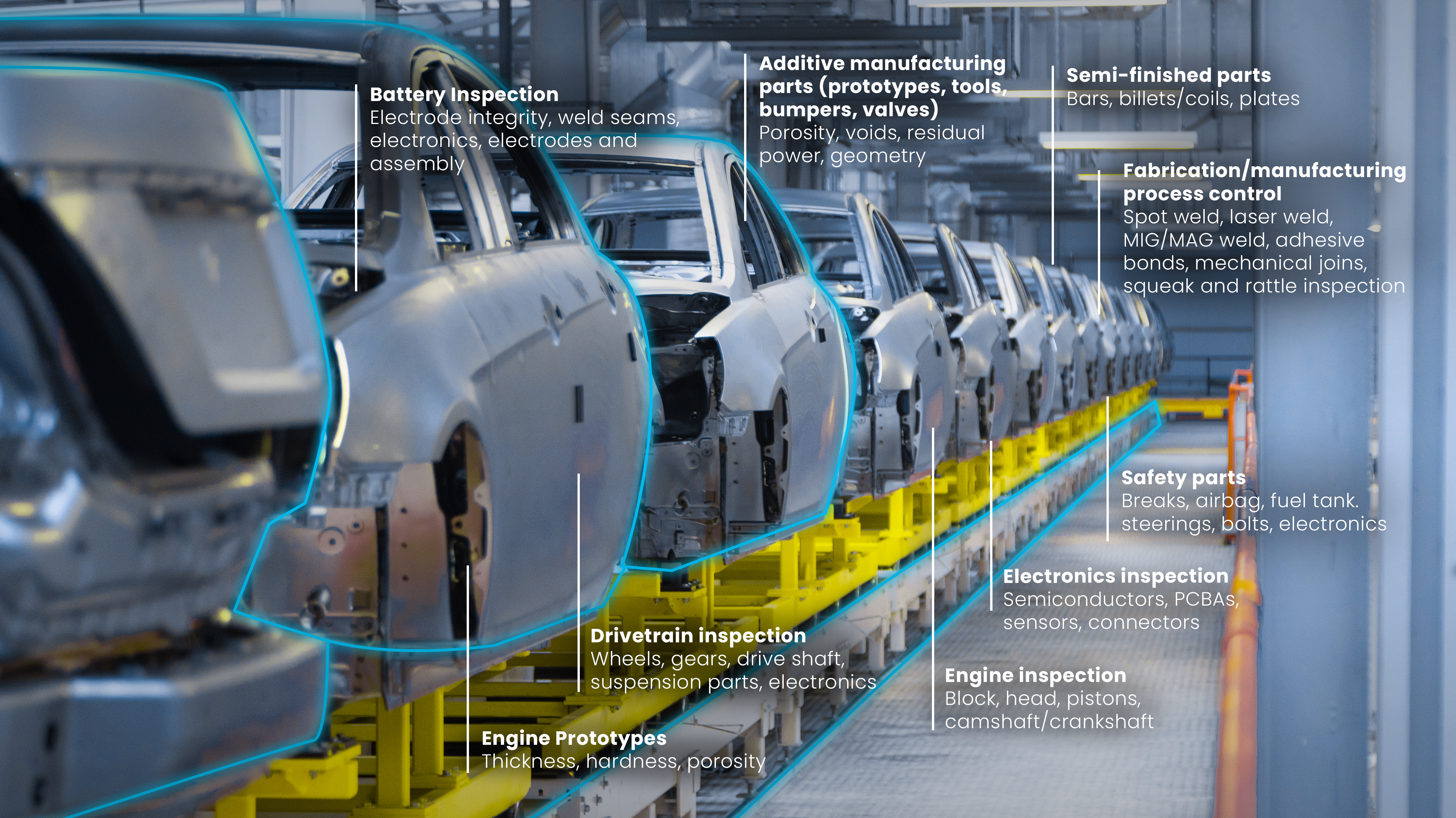

Waygate Technologies offers industry-leading solutions for the rigorous quality requirements of the automotive industry — from castings and composites to weld and bond seam inspection to general electronics, sensors and battery scanning. Bring fast, accurate, cost-effective NDT solutions to the floor of your plant.

We bring fast, accurate, and cost-effective automotive NDT equipment to the floor of your plant

Automotive industry has seen a shift from manufacturing cars, to manufacturing computers with engines on wheels ... This opens new set of risks and challenges.

When going from internal combustion engines to hybrid and electric vehicles, major components, equipments and their corresponding supply chain is affected.

The need to keep up with the high demand of vehicles out the door requires defects to be low, and defect detection to be quick.

A data thread across the value chain is becoming increasingly important ... From raw materials to completed vehicle, tracing at every step will be key for tax credits, traceability of faults, etc.

From castings and composites to weld and bond seam inspection to general electronics, sensors and battery scanning

Collaborating with some of the world's most prominent partners in the automotive industry to deliver peace of mind

Automotive NDT equipment made for your challenges

Today’s manufacturers are creating more complex parts than ever before — making inspections more challenging. Our industrial non-destructive testing solutions give manufacturers the ability to inspect and measure these complicated components and assemblies at the speed of production, so innovation can keep marching forward.

Li-ion batteries are among the most powerful energy storage devices commonly used in portable electronic devices, stationary power sources and electric vehicles. Our broad portfolio of premium radiography systems supports not only R&D as well as the post-mortem analysis of defective li-ion batteries to analyze the means of failure, but also fast CT inspection providing safe and secure production control with a reliable inspection of all vital parts.

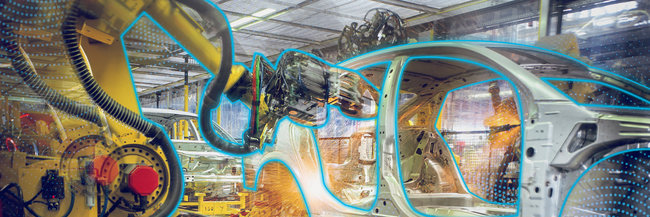

Inspect glue lines and seams on automotive body panels with confidence and convenience. Waygate Technologies' offers ultrasonic flaw detectors, scanners, accessories and software that are just as precise as they are easy to use, as well as industrial radiography solutions that offer an ideal balance of inspection accuracy and speed.

We help automotive manufacturers achieve faster product ramp up times, optimize production processes and improve product quality with a range of advanced industrial NDT solutions. From our trusted and easy-to-use Krautkrämer lab tanks, to precise industrial radiography and CT inspection and metrology solutions, to remote visual inspection equipment with the best in class image quality, more accurate, efficient cast parts inspections are possible.

For the highest level of confidence in your electronics and sensor inspections, we have developed the most advanced industrial radiography systems to help you uncover even the smallest of defects. This includes nano- and micro-focus non-destructive automated X-ray inspection (AXI), as well as automated inline CT inspection solutions to improve productivity and quality on the production floor.

Waygate Technologies can help you achieve reduced weld inspection times, while increasing the probability of detection. With a range of solutions from versatile, ergonomic ultrasonic inspection tools that provide documentation of inspection results right on the device to our video borescopes with the highest image quality available, it's never been easier to get fast and accurate weld inspections you can feel confident about.

Get in touch with one of our Waygate Technologies subject matter experts.

Why choose Waygate Technologies

Industry-Leading Precision and Performance

Waygate Technologies provides cutting-edge ndt solutions designed to meet the highest quality standards in the automotive industry. Our advanced radiographic, industrial CT scanning, ultrasonic, and remote visual inspection technologies ensure fast, accurate defect detection—helping manufacturers enhance product integrity while maintaining efficiency and cost-effectiveness.

Solutions for the Future of Automotive

As the industry transitions to electric and hybrid vehicles, our non-destructive testing (NDT) solutions adapt to new materials, intricate components, and evolving regulatory requirements. Whether inspecting battery systems, weld seams, or composite structures, our high-performance technologies provide the speed and accuracy needed to keep up with modern production demands.

Global Expertise, Data-Driven Insights

With a worldwide network of experts and innovative data management tools, we transform NDT from a routine inspection into a strategic advantage. Our solutions offer real-time analytics, seamless integration into production lines, and enhanced traceability—helping you achieve smarter, more efficient, and more reliable manufacturing processes.

Resources

Non-Destructive Testing (NDT) in the automotive industry is a quality control method used to inspect materials, components, and assemblies without causing damage. NDT techniques, such as ultrasonic testing, eddy current testing, and X-ray inspection, help detect defects, measure material properties, and ensure the safety and reliability of automotive parts. These testing methods are essential for maintaining high manufacturing standards, improving efficiency, and preventing failures in critical vehicle components.

While Non-Destructive Testing (NDT) is essential for ensuring the quality and safety of automotive components, it does have some limitations. Certain NDT methods

require specialized equipment and trained personnel, which can add to operational costs. Some techniques, such as X-ray or ultrasonic testing, may have difficulty detecting very small or subsurface defects in complex geometries. Additionally, environmental factors, material properties, and surface conditions can affect the accuracy of results. Despite these challenges, NDT remains a crucial tool for improving reliability and reducing manufacturing defects in the automotive industry.