The world‘s most flexible industrial dual-tube micro/nano CT scanner

The V|tome|x M Neo computed tomography solution sets a new standard in flexibility, speed, and detection quality, making it the ultimate choice for a wide range of 3D metrology and analysis applications in various industries for parts up to ø500 mm x 700 mm and 75 kg.

This highly productive Dual|tube scanner with its 300 kV Microfocus and optional 180 kV Nanofocus X-ray tubes delivers improved manipulator concept and motorized Focus-Detector-Distance (FDD) adjustment highest accuracy at unprecedented speeds – helping you dramatically optimize your lab research results and production quality processes to meet today’s und future increasing demands.

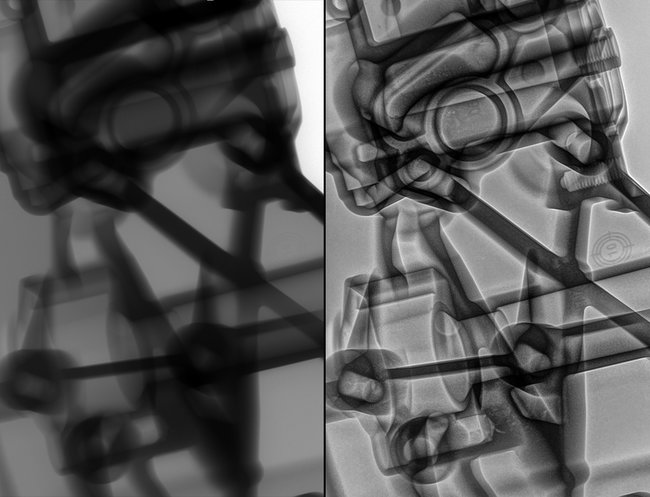

With this CT scanner you can see smallest details <1 µm with Microfocus or <200 nm with Nanofocus X-ray tube.

Premium 3D analysis industrial CT starts here

Our powerful industrial computer tomography (CT) system, designed for 3D metrology and analysis, provides industry-leading magnification at 300 kV. Together with Scatter|correct technology scatter artifacts are automatically removed for higher image quality. The variety of exclusive high performance detectors and proprietary premium CT technologies, the Phoenix V|tome|x M Neo revolutionizes CT inspection and 3D metrology – delivering faster scans and higher throughputs without compromising image quality and measurement precision.

Advancing imaging and analysis with superior performance

The Phoenix V|tome|x M Neo is a next-generation industrial CT system, building on the success of the widely-used Phoenix V|tome|x platform with over a thousand installations worldwide. It offers remarkable advancements, including improved image results, an expanded scanning area for larger and heavier samples, variable focus detector distance, and a new cabinet design for enhanced flexibility and accessibility.

The Phoenix V|tome|x M Neo is a versatile system suitable for a wide range of 3D metrology, research, and evaluation applications in laboratory environments. Additionally, its automation capabilities make it well-suited for precise testing in production environments, providing reliable results for industrial applications.

Product Highlights

- High-performance Micro- (300 kV / 500 W) and Nanofocus (180 kV / 20 W) X-ray tubes for best resolution and speed

- Exclusive Dynamic 41 detectors with 10x increased sensitivity compared to state of the art DXR detectors to benefit from up to 2-3x faster CT scans or doubled resolution

- Proprietary High-flux|target allows higher power on a smaller focal spot to cut scan time in half

- Compact design just requiring 10 m²

- A solution with high serviceability

- Easy to access maintenance door

- Re-engineered manipulator enabling high efficiency

- Larg L-shaped sliding door for easier part loading

- Flexible loading via internal or external crane

- Highly versatile control panel

- Expanded scanning area for larger and heavier parts

- Expanded scanning area suitable for inspecting both small and large parts

- High variable focus detector distance

- Efficiency-driven automation

- Automatic defect recognition (ADR) workflows through X|approver software

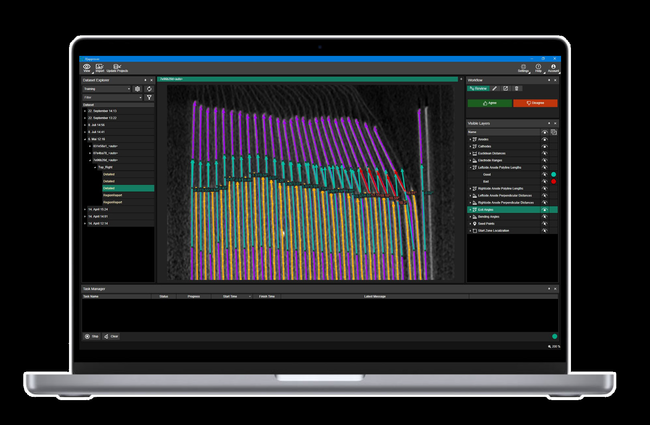

- Equipped with the latest Datos|x software providing full control of your data acquisition and even faster data reconstruction

Advanced Scatter|correct technology automatically removes scatter artifacts for artifact-free precision CT results on the quality level of fan-beam CT scanned several hundred times faster with advanced cone-beam CT.

There is more information in an images acquired within a 2D application or slide taken from a CT scan visible for the human eye. The system includes Waygate Technologies X|act NDT inspection software with industry leading Flash!™ intelligent image processing technology unveil details that are not visible before. Users benefit from two versions:

- Flash! (for general NDT use such as casting inspection)

- Flash! Electronics (optimized for Electronics inspection)

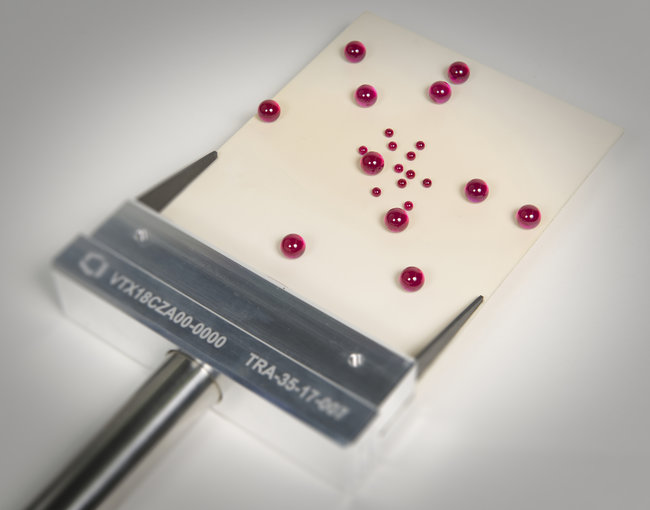

With Ruby|plate and True|position technology, the Phoenix V|tome|x M has a specified accuracy of SD ≤ (3.8 + L/100 mm) µm, referring to VDI 2630-1.3 guideline. For all other positions between the VDI positions, a remarkable accuracy of SD ≤ (5.5+ L/100 mm) µm can be reached.

Benefits

Broader sample size range at increased sample weight

Increased flexibility, speed, and detection quality with less scatter and outstanding metrology precision

Effortless, faster loading and unloading

Simplified maintenance for greater productivity and reduced downtime

What Our Customers Are Saying

Product Specifications

Detail

Data

X-ray tube

Open directional high-power microfocus X-ray tube, closed cooling water circuit. Optional additional open transmission high-power water cooled nanofocus X-ray tube Horizontal dual tube orientation for improved image acquisition

Max. voltage / power

300 kV / 500 W. Alternatively available with 240 kV / 320 W microfocus X-ray tube. Dual|tube option for nanoCT®: additional 180 kV / 20 W high-power nanofocus tube with Diamond|window, high precision rotation unit, easy tube exchange just by a push of a button

Geometrical magnification (3D)

1.29 x to 100 x; up to 225 x with nanofocus X-ray tube

Detail detectability

Down to < 1 μm (microfocus tube); optional down to 0.2 μm (nanofocus X-ray tube)

Min. voxel size

Down to 2 μm (microfocus), Optional 1 μm with Dynamic 41|100; Optional down to <0.5 μm (nanofocus + Dynamic 41|100)

Detector type

(all according US ASTM E2597 standard)

Temperature stabilized Dynamic 41|200 large area detector with superior image and result quality, 410 x 410 mm (16” x 16”), 200 μm pixel size, 2036 x 2036 pixels (4 MP), extremely high dynamic range > 10000:1. Optional Dynamic 41|100 detector 410 x 410 mm (16” x 16”), 100 μm pixel size, 4048 x 4048 pixels (16 MP) for doubled CT resolution

Manipulation

Granite based precision 6-axes manipulator

Variable focus-detector-distance

Optional 310 mm - 900 mm (12.2’’-35.4’’)

Max. sample diameter x height

310 mm x 700 mm (12.2’’ x 27.5”) in height; up to 500 mm (19.7”) in diameter when using an offset scan

Max. sample weight

75 kg (165 lbs.), high accuracy CT

Max. focus object distance

700 mm (27.55“) applied for microfocus tube

System dimensions W x H x D

Appr. 2,911 mm x 2,177 mm x 1,710 mm (114.6“ x 85.7“ x 67.3“)

System weight

Appr. 9,500 kg (20,940 lbs.)

Optional Click&measure|CT

Included

Double CT resolution at the same speed, or double throughput at the same quality level as 200 µm pitch DXR detectors. Compared to 16-bit detectors, the optimized 14-bit technology offers the highest efficiency with a dynamic range of 10000:1 and thus saves time in use and also generates less noise in the image

Scan even larger parts with up to ~70% larger scanning volume

The BHC|Multi tool corrects streaking artifacts which typically occur as multiple dark streaking bands positioned between dense areas in multi-material samples

Adaptive scatter correct filter offering unrivaled image quality by significantly reducing artifacts caused by reduced grey values in high absorbing sample CT datasets

This easily removable holder allows automatic change of different samples

In combination with the Sample|changer, the optional Filter|changer allows to perform mixed batch CT scans

In the aerospace industry, the Phoenix V|tome|x M Neo serves as a versatile and indispensable tool with diverse applications. It excels in inspecting and evaluating critical components such as air foils, additive manufactured parts used for spare parts and maintenance purposes, cutting-edge carbon fiber technology, and intricate electronic components for satellites.

The Phoenix V|tome|x M Neo is a powerful solution for battery testing, offering precise anode and cathode measurements, as well as failure analysis for various battery cell configurations like prismatic, pouch, folded, and stacked. Its advanced capabilities ensure the reliability and efficiency of battery technologies, contributing to their enhanced performance in various applications.

Whether it's assessing microstructures, examining solder joints, or inspecting circuit boards, the Phoenix V|tome|x M Neo provides valuable insights that contribute to enhancing product reliability, optimizing manufacturing processes, and accelerating research and development efforts in the electronics industry.