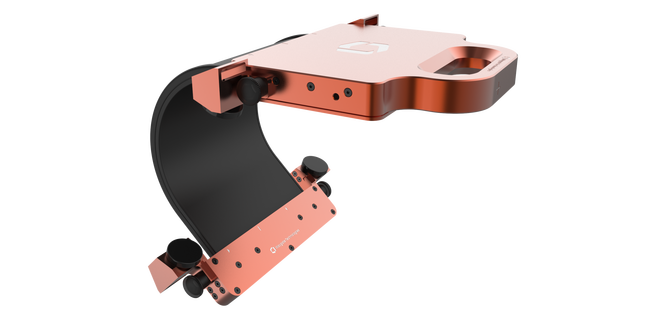

DXR Flex 1025 & 1043

Designed specifically for industrial applications, the next generation of DXR detectors delivers rugged reliability tailored to meet the demanding requirements of weldment inspection. Engineered with customer needs in mind, the DXR Flex Detector excels in three standout features: exceptional flexibility, user-friendly operation, and rapid performance. This combination ensures a versatile and efficient solution for diverse inspection tasks.

A standout feature of the DXR Flex Detector is its dual-sided exposure capability. One side of the detector is flexible, while the other is rigid, catering to elliptical radiographic exposures. This dual functionality ensures comprehensive and precise inspections, meeting diverse application needs.

Highlights

Benefits

- Flexible: X-ray detectors offer unparalleled versatility, with dual-sided exposure capabilities

- One side features a flexible design ideal for tubular contact radiography, while the other side is rigid

- Easy: Durability meets convenience with a rugged casting that includes built-in magnets, ensuring fast and effortless weld access.

- The detectors are also equipped with industrial shielding, providing protection.

Features

- The DXR 1025 and 1043 X-ray detectors are built for industrial use.

- They deliver rugged reliability essential for inspecting a wide range of weldments.

Applications

- pipeline weld inspection

- fabrication shop inspections (pipe spool, vessels, tanks, etc.)

- weld inspection (piping)

- crack detection

DXR Flex detector is used in a variety of market segments

- O&G

- Aerospace & Space

- Power

- Pulp & Paper

- Military & Defense

Each DXR Flex Detector is built to withstand the harshest conditions. Encased in a rugged design with magnets for quick and easy weld access, the detector is industrially shielded to endure drops, knocks, and radiation, ensuring extended operational life. The durability of this detector is a testament to Waygate Technologies’ commitment to quality and reliability.