Powerful intelligence, by touch or voice

Driven by advanced analytics to inspect in entirely new ways, the more intelligent Mentor Visual iQ+ borescope uses computer vision and machine learning to increase data quality while reducing inspection times. The new voice command feature lets inspectors perform measurement, data sharing, and more without needing to touch the MViQ+ directly.

Designed with complex inspection applications in mind, the Everest Mentor Visual iQ+ video borescope meets the highest standards in image quality, 3D measurement capability, and workflow automation.

Advanced 3D Inspection Software

Real3D™ measurement combines fully surfaced point cloud visualization, advanced measurement algorithms and an insightful 3D Surface Mask to enable more accurate and repeatable measurement decisions. Choose from Real3D Stereo or 3D Phased Measurement which allows measurement on-demand without changing tips.

Each of these technologies is compatible with some or all measurement types to help get the measurement needed in every application. They include basics like length, depth point to line and area, but also specialty types including missing corner area, area depth profile, automatic blade tip clearance and radius gauge for boro-blending assessment.

Aside from measurement types, Real3D provides advanced tools such as depth assist and measurement plane to further increase accuracy of measurements.

What's New with Measurement?

- Missing Corner: measures the area and edge lengths of a missing blade corner with 1 point designating the tip and up to 23 additional points placed along broken edge. Now inspectors can accurately determine how much material has detached for quick engine serviceability assessment.

- Surface Angle: measures the angle between a reference plane and an angle plane. For the first time on any borescope, we can now determine deformation or deflection of a compressor blade to provide a the value in degrees. Surface angle uses a simple 4 cursor workflow very similar to depth.

- Auto Area: generates masks quickly to calculate an area you specify.

Featured

HD Resolution and 3D Image Stitching

This industrial borescope offers on-demand measurement with the most advanced 3D capabilities, providing more accurate measurement from increased distances. 3D Stitching combines individual images and corresponding point clouds to a larger image which enables measurement of larger defects across multiple images and the ability to accurately locate the position of defects in relation to a fixed point-of-interest. Users can adjust cursor placements in the fully-surfaced Point Cloud to deliver results with confidence.

What's New with 3D Stitching

- 2X Faster: users can leverage the MViQ+'s increased processing power to run more features simultaneously.

- Increased Image Limit to 10: the MViQ+ can now handle composite images consisting of up to 10 images where the original MViQ had a limit fo 5.

- Optimized Algorithms for Improved Point Matching: we are constantly improving our stitching algorithms to give users even more increased performance.

Featured

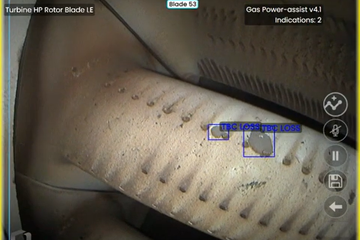

Defect Detection and Blade Counting

Leverage computer vision and machine learning to help improve consistency and reliability of inspection tasks and increase the overall quality of an inspection output. The Mentor Visual iQ+ enables users to leverage analytical models from multiple sources.

- Waygate Technologies analytics Gas Power-assist and Blade Counter developed to improve inspection reliability and data integrity.

- Third Party partner analytics are available directly on the MVIQ+; users can leverage Aiir Innovations’ aviation commercial engine models for defect detection.

- For customers developing their own analytics, the MVIQ+ enables deployment to a global team.

- User Guides are available in the Resources section for each analytic outlining applicability, performance metrics, operating procedures, frequently asked questions, and more.

What's New

With continued focus on robust detection and categorization, Gas Power-assist 5.0 is now available.

- Analytic models updated with additional training images from industry partners to improve performance

- Increase in True Positive Rate and decrease in False Positive rate for a wide variety of gas turbines in aerospace and power applications.

Featured

TrueSight™ Image Software

TrueSight™ provides a blend of high resolution image capturing and processing functions, precision optics and a powerful suite of proprietary image transforms used to enable better visual inspection decisions.

The suite of image transforms is included in the Pro package and available for Start and Enhance.

This POD SW includes the following (click to watch videos): Live 3D Stereo, Adaptive Noise Reduction (ANR), Dark Boost, Distortion Correction, Inverse+, Variable High Dynamic Range (VHDR) and Color Saturation.

Featured

Cloud Connectivity and InspectionWorks

The MVIQ+ comes with InspectionWorks, a secure and scalable cloud-based inspection platform that integrates every component of the nondestructive testing , turning data into useful intelligence for faster and better decisions.

- Make your devices ready Access centralized cloud repository to enable download of MDI, ADR, or media to the device.

- Launch your inspection plan Conduct your inspection using standardized templates powered by MDI (menu directed inspections).

- Centralize your data Effortlessly transfer data for unified access using Push2IW.

- Leverage your AI Access your or our ADR algorithms to analyze and increase processing efficiency.

- Software updates Connect to the network to keep updated with the latest features. You can get started today with your free InspectionWorks account.

Featured

2-Way Communication

To enable repeatable image capture of every blade in each stage, the updated protocols let the MViQ+ video borescope and the Rhinestahl FutureDrive NG+ turning tool perform 2-way communication. Previous time delay image capture can sometimes cause errors and consume unnecessary waiting time between stop and image capture. Now consistent images are provided in less time.

Featured

Customize Your MViQ+ Package

Customers can choose between 3 MViQ+ base packages to determine which Mentor Visual iQ+ features are right for them.

MViQ+ START

Touch Screen

40GB User Storage

Menu Directed Inspection

Comparison Measurement

InspectionWorks

Far Field Audio

90-Day Analytics Trial

Free Software Updates

MViQ+ ENHANCE

START, plus:

Interchangeable Probes

80GB User Storage

HD Imaging

Turning Tool 2.0

1-Year Analytics (Blade Counter, GasPower assist)

MViQ+ PRO

START and ENHANCE, plus:

160GB User Storage

2-Year Analytics (Blade Counter, GasPower assist)

All Probability of Detection Measurement Bundle options

Choose a Measurement Bundle

Decide between Real3D Stereo, including traditional Stereo measurement, and Real3D Phase measurement, then select one of the two Probability of Detection (POD) Measurement bundle is included in PRO, can be added to START or ENHANCE, and includes: Variable high Dynamic Range, Adaptive Noise Reduction, Distortion Correction for wide FOV, DarkBoost, Inverse+, Color Saturation, Long Exposure, White Balance, and image transformation presets.

POD Basic Measurement

Probability of Detection

3D Stitching

Live 3D Stereo

Overlay

Basic measurement types: length, point-to-ine, depth, depth profile, area, angle and multi-segment

POD Advanced Measurement

Basic, plus:

Area Depth Profile

Radius Gauge

Auto Blade Tip Clearance

Auto Area

Surface Angle

Measurement Plane

Rugged Design

Constructed with military-grade durability (MIL-STD) to withstand the rigors of the industrial workplace, you can trust your Mentor Visual iQ+ videoscope device to deliver top performance in even the harshest environmental conditions.

Standard compliance and classifications:

- MIL-STD-810H United States Department of Defense Environment Tests Sections 501.5, 502.5, 506.5, 507.5, 509.5, 511.5, 514.6, 516.6, 521.3

- MIL-STD-461G United States Department of Defense - Electromagnetic Compatibility with RE102 and RS103 - ABOVE DECK

- Standards compliance Group 1 Class A; EN61326-1, IEC CB Scheme, UL/EN/CASE-C22.2 61010-1, IEC 62133, UN/DOT T1-T8, EU RoHS 2, EU RED Directive, ISTA 2G, UKCA

- IP rating: IP65 (assembled), IP55 (disassembled)

Versatility to the Max

Performing video borescope inspections require skilled technicians working in challenging environments. Deploying the proper accessories for the job can ensure inspections are performed properly, ergonomically and efficiently.

Perhaps most important is selecting the appropriate optical tip for your application; especially when performing measurements during the inspection. A full list of optical tips and specifications can be found in the VideoProbe Accessories Catalog.

In addition to optical tips, the Catalog also includes hands free mounting options; guide tubes, rigidizers, and grippers; centering devices; measurement verification blocks; batteries and power supplies; case and storage options; and more.

Specialty Probes:

- UV VideoProbe adapter combines a UV light sources with the MVIQ+ for the optimal solution for florescent penetrant inspections. Learn More

- LongSteer probe provides up to 30-meter length for long winding inspections. Learn More

- Borescope Adapter connects a rigid or flextible borescope to the MVIQ+ for image capture and data management. Learn More

- Working Channel Probe is available in 6.2mm diameter with a full suite of working tools to expedite return-to-service.

Services to Minimize cost of ownership

The Visual Care Plan (VCP) is a comprehensive service plan intended to help you decrease video borescope downtime, save on repairs, conserve assets, and maintain peace of mind. Our VCP includes: prioritized repair response; yearly preventative maintenance; discounted accessories, repairs, and upgrades; and training credits.

The FLEX service lets you buy guaranteed RVI equipment uptime instead of owning and maintaining the equipment yourself. Choose an inspection kit to meet your needs and get peace of mind with assured availability for a predictable price. It has all the benefits included in the Visual Care Plan; flexible subscription terms (36-60months); immediate deployment of spare system during repair; and repairs for both leased and owned equipment.

Product Resources

Our support team offers consultations to help you figure out which Borescope will be best fit for your inspection device needs. Contact one of our experts.

With the power of Real3D™, the MViQ can measure length, area, depth, multi-segment, depth profile, measurement plane and area depth profile.

The Mentor Visual iQ has 1.2 megapixel HD sensors to increase image quality up to 1.7 times clearer than standard models operating at 440K pixels. This allows you to zoom into indications until they're nearly 70 percent larger, ensuring the most accurate analysis possible.

We work to get you your rental equipment fast, so you can lower your downtime. Learn more about our rental programs here.

A free 90-day trial should be activated after installing your 3.7 software. After that, contact your local Waygate Technologies sales representative.

Yes. Waygate Technologies is committed to delivering Inspection Solutions to the inspection industry. Please contact your local Waygate Technologies sales representative to discuss your needs.

Due to the common nature of gas turbine architecture and defect classifications, it is likely that this ADR analytic remains application to other gas turbine types beyond those listed in section 4.0.

Note that LMS100, LM2500, AND LM6000 are aeroderivative of the CF6 aero gas turbine series.

ADR improves consistency and reliability of inspection tasks by leveraging Computer Vision technology to assist the trained Inspector in conducting the visual inspection. It also reduced the probability of missing indications on critical turbomachinery components. ADR also provides automatic annotation for the user to approve, and it increases the overall quality of inspection output.

No. The analytics operate entirely standalone within the device.

Yes. The ADR can process on recalled images within the MViQ "Flame" handset. Such images can be: those that have either been previously processed using this analytic; or raw/unprocessed images. Inferences can be generated and subsequently saved for presentation or inclusion into the inspection report.