Krautkrämer SpotVision

With increasing vehicle production, the automotive industry is turning to image-based inspection to reduce downtime while maintaining high quality standards.

Waygate Technologies' Krautkrämer SpotVision, developed in collaboration with automotive manufacturers, is the fastest, easiest, and most accurate phased array solution for spot weld inspection. It provides confidence, parts are properly welded. This increases productivity as well as ensures product safety and that quality standards are met at all times.

Highlights

Benefits

- Increase process control

- Avoid false negatives

- Reduce training time

Features

- 2D matrix phased array probe

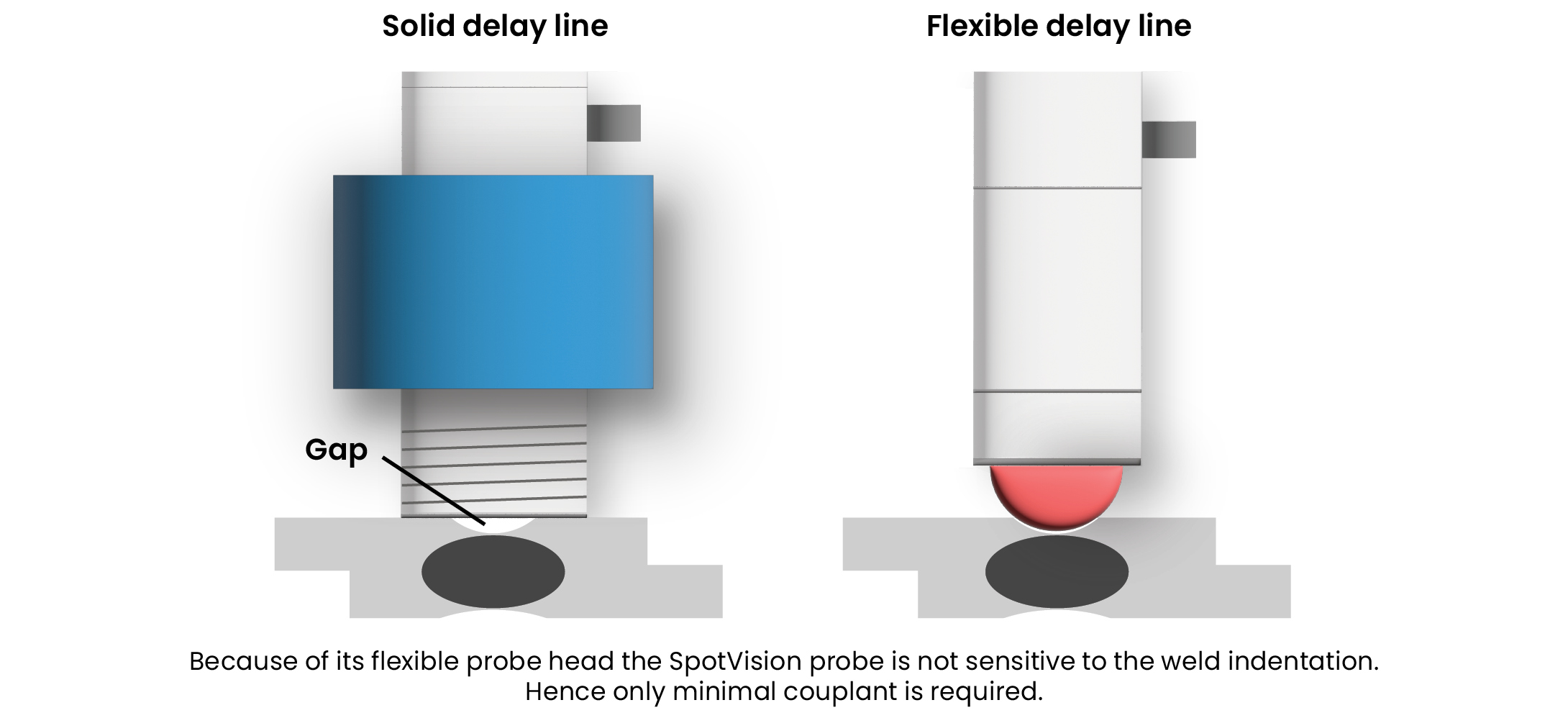

- The membrane is filled with fluid, allowing it to adapt to uneven surfaces and the overall complex geometry of spot welds

- With Total Focusing Method (TFM) image processing, a higher resolution and measurement accuracy with a comparable phased array is achieved

Applications

- Automotive industry

The solution combines a phased array probe and the Mentor UT phased array flaw detector for comprehensive insights at the highest level. One of the most remarkable features of the newly developed 2D matrix phased array probe is its flexible delay line, filled with liquid. This allows it to adapt to the overall complex geometry of spot welds. The flexible probe also provides optimal acoustic coupling, avoiding false negatives and minimizing process delays.

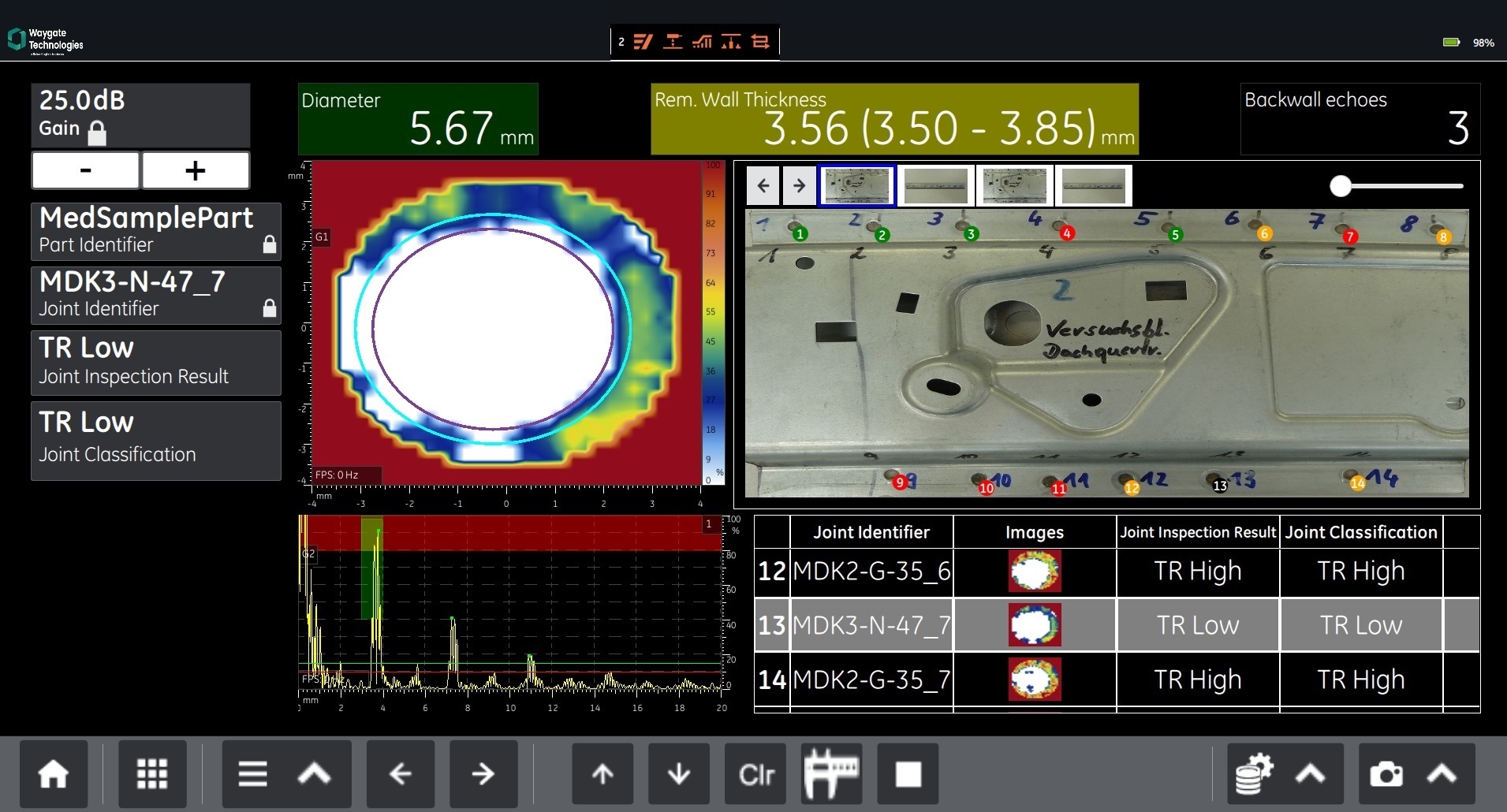

The 2D matrix probe is combined with Total Focusing Method (TFM) imaging technique. This achieves higher resolution and measurement accuracy than with a comparable phased array. Thanks to TFM, each element is fired individually and sequentially while all elements are listening.

Krautkrämer SpotVision is easy to set up and operate, reducing the need for training for qualified inspection personnel. This is due to the software's intuitive user interface. In addition, Mentor PC Live software connects the instrument to a PC via Ethernet, which is especially helpful when the operator is in a different location.

Technical Specifications

SpotVision Technical Details & Specifications

Accessories

Base Kit UP680023

- Incluye cargador/alimentador de potencia, batería externa, módulo de comunicación, maleta de trasporte, adaptador para conexión de palpador.

- Palpador: G13MAPA-32 ( palpador array 2D de 32 elementos para SpotVision)

- Bloque de referencia (Bloque de referencia con 9 lentejas artificiales con diámetros entre 2,5 y 6,5 mm)

Krautkrämer SpotVision Mejora Kit UP680024

- USB drive que incluye Software SpotVision UT SW (contiene Software Aplicación para instalación en SpotVision y distinta documentación)

- Palpador: G13MAPA-32 ( palpador array 2D de 32 elementos para SpotVision)

- Bloque de referencia (Bloque de referencia con 9 lentejas artificiales con diámetros entre 2,5 y 6,5 mm)

TFM is short for Total Focusing Method. In brief, each element is fired individually and sequentially, while all elements are listening. So the image reproduction is not limited by the number of pre-defined focal laws. With the TFM image processing, a higher resolution and measurement accuracy with a comparable phased array is achieved.

With a flexible delay line, less couplant would be required for optimal acoustic coupling and the probe adapts easily to uneven surfaces, like spot weld indentations. As a result, false negatives are avoided.

Yes, you can. SpotVision is used in combination with Mentor UT, a multi-application phased array device. In the automotive industry, also the Bond Scanner solution to inspect adhesive bonding can be used.

For nuggets in the diameter range of 2.0 - 6.0 mm, the measurement accuracy is ±0.5 mm / ±20 mil with a certainty of 90% according to VDA5 – Gauge R&R Analyses.

Krautkrämer SpotVision is part of the Waygate Technologies portfolio for the inspection of joints. This includes the Krautkrämer Bond Scanner for inspecting adhesively bonded joints with fast and easy to interpret 100% coverage. Both solutions are designed for ideal use in combination with the Krautkrämer Mentor UT phased array flaw detector.