What is included in Agfa's assortment of film types?

Industrial X-ray films are produced by a limited number of manufacturers in an assortment for use with or without intensifying screens and filters. The selection of a particular film type not only depends on economics but in particular on the required, often prescribed, image quality.

What is included in Agfa's assortment of film types?

Agfa’s assortment of industrial standard radiographic film comprises the following types in sequence of increased speed and granularity : D2, D3, D4, D5, D7 and D8, complemented with the very fast films F6 and F8.

Note: Industrial X-ray films made by Agfa carry the generic name STRUCTURIX. The various types of STRUCTURIX film are identified by the number which follows the generic name, e.g. STRUCTURIX D4. For ease of reading the indication “STRUCTURIX “ is omitted in the text from here on.

The ultra-fine-grain D2-film is used in the radiography of very small components, when optical magnification is applied to allow very fine details to be observed.

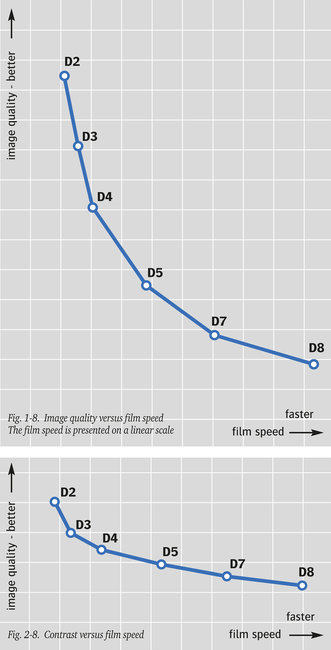

D8 is used for the examination of big castings and steel reinforced concrete. D10 film is also produced for exposure monitoring purposes. Figures 1-8 and 2-8 show the relationship between film speed and image quality and film contrast respectively.

In addition to these graphs, figure 13-16 gives a graphical representation of relative image quality as a function of relative dose and exposure time (film speed) for D-films and computer-assisted CR and DR techniques.

Agfa has developed special intensifying screens specifically for use in combination with F6 and F8 films, see section 6.3. These so-called rapid cycle film screens are usually referred to as RCF-screens. F8 has the highest film speed. Depending on quality requirements, F6 is mostly used for weld inspection on lay-barges; since it shortens examination time by a factor 10, see section 6.3.

Figure 3-8 shows graphs of relative exposure time versus density for the entire Agfa D-film range. For density 2, the difference between a D8 and a D2 film is a factor 14 (10(3.25-2.1) ), at 200 kV.

Part of the Agfa film range with relative exposure factors and code classification has been listed in table 1-8 for various radiation intensities:

Note I: It is common practice to compare relative exposure factors with those of D7 film, which are shown bold as reference value 1.0 in the table.

Note II: The numbers (1) to (5) used in the table indicate the use of the following screen types:

- without lead screens

- with lead screen 0.027 mm thickness

- with lead screen 0.027 mm thickness

- with lead screen, front 0.10 mm, back 0.15 mm thickness

- with fluorometallic screen (RCF)

Note III: Developing process for table 1-8: automatic, 8 minute-cycle, 100 seconds immersion time in developer G135 at 28˚C. Note IV: The relative exposure factor depends not only on radiation intensity, but also on exposure time and is, therefore, not a constant value.