FLASH! X-Ray Digital Image Processing Software Flash!

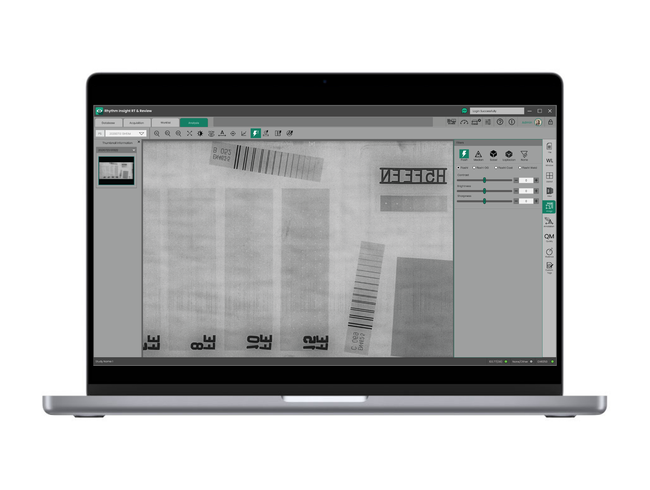

Detect even the smallest defects with advanced digital radiolographic image processing technology

Our most advanced intelligent image processing software just got smarter. The next generation of FLASH! is here and now comes standard on all Waygate Technologies X-ray software platforms.

Image processing technology starts here

Advanced digital radiographic image processing technology starts here

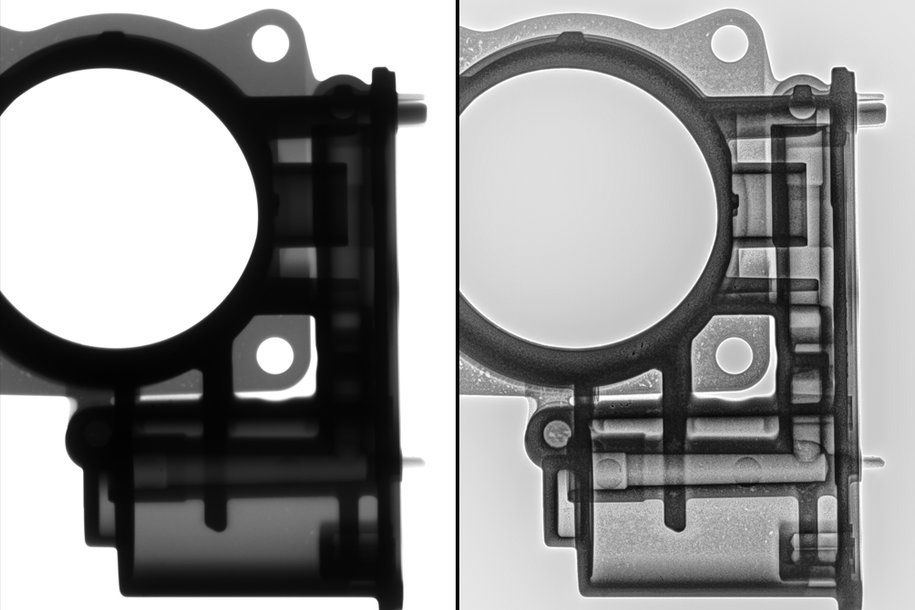

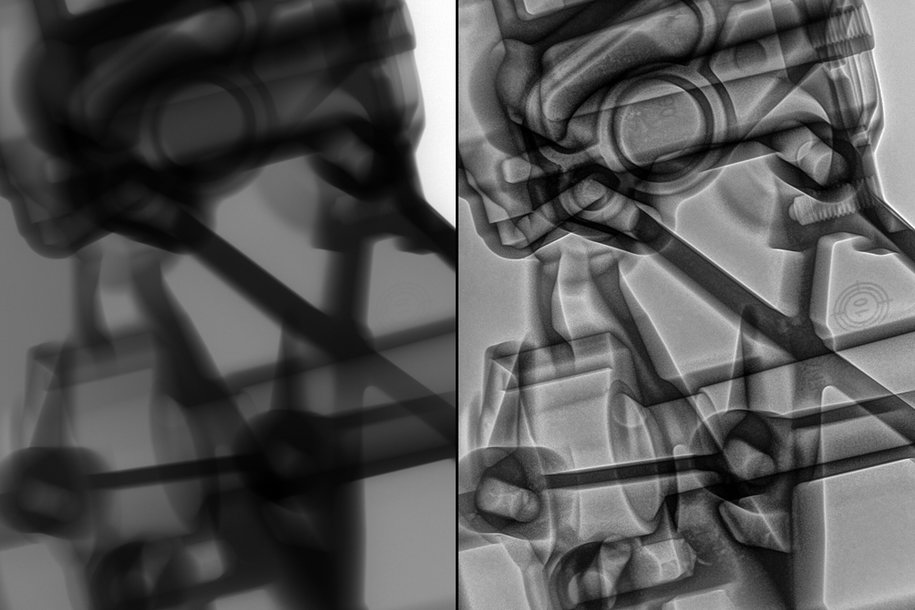

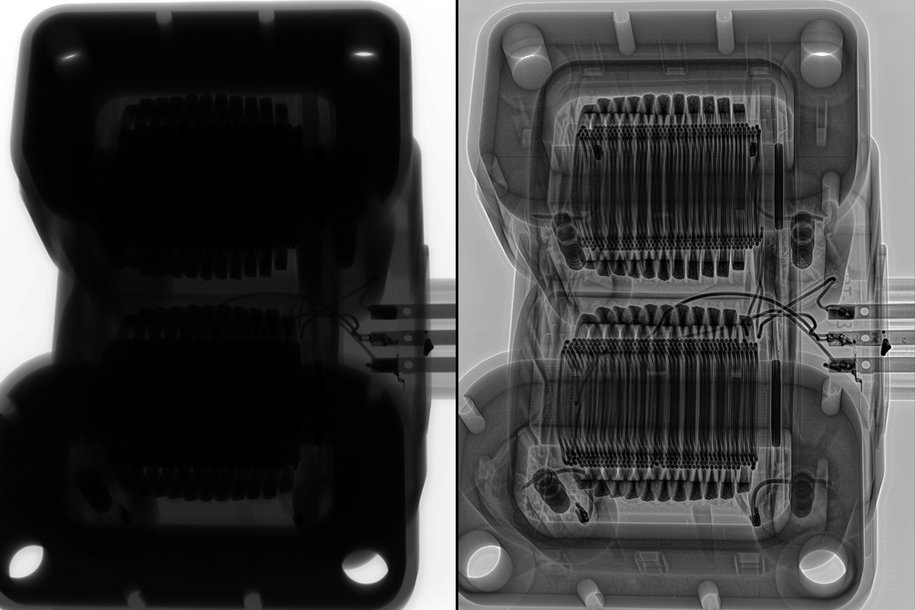

When performing radiographic inspections, every detail counts. That’s why we’ve combined 25+ years of industrial radiography experience with cutting edge imaging technology to bring you the fastest and most accurate image processor available. With a single click, FLASH! automatically combines high- and low-density areas into one clear image, with no manual adjustments required.

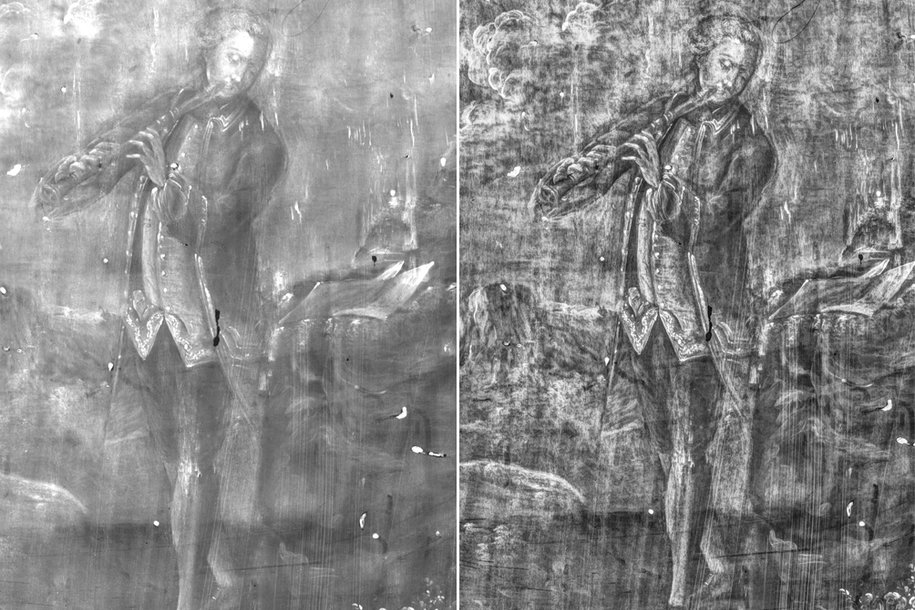

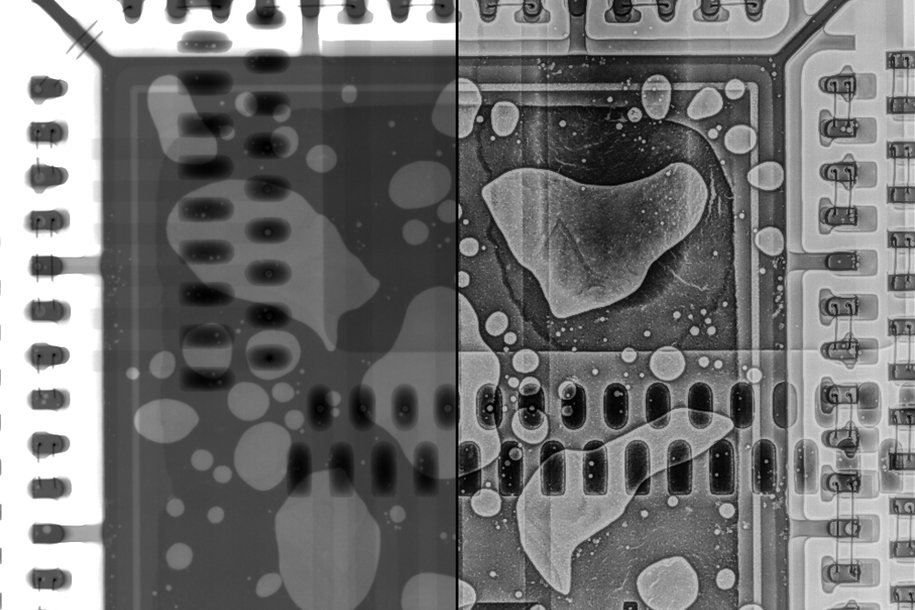

FLASH! is the hardest working image processing system available, capable of performing more than 50,000,000,000 calculations per image, or 1,000 calculations per pixel. It’s also one of the most versatile non-destructive testing (NDT) tools available, capable of performing equally accurate inspections on an aerospace & automotive casting, a battery, an electronics, a gas pipeline, a critical weld or even a work of fine art.

Enjoy the benefits of a faster, more accurate inspection process with Flash!: improved productivity, reduced downtime, and results you can trust.

Highlights

Benefits

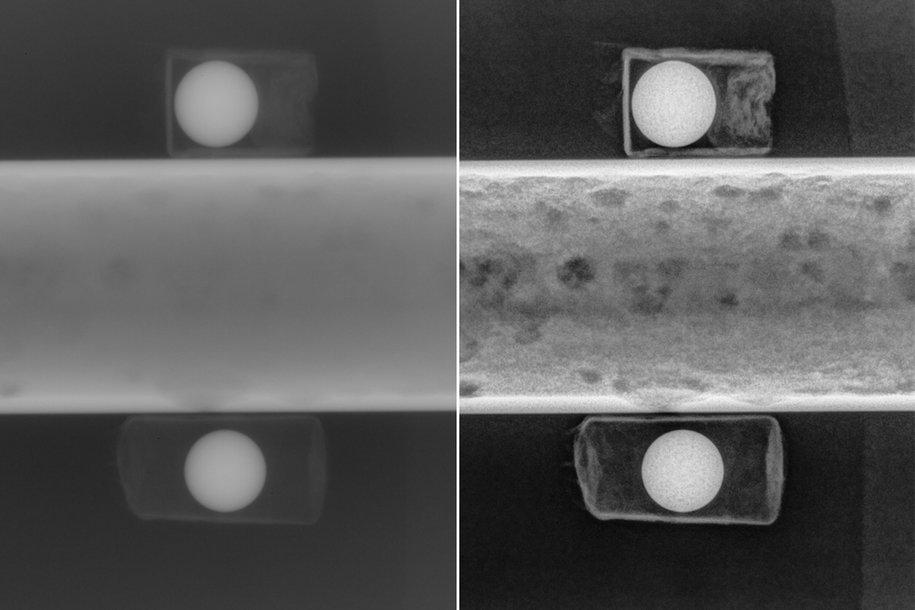

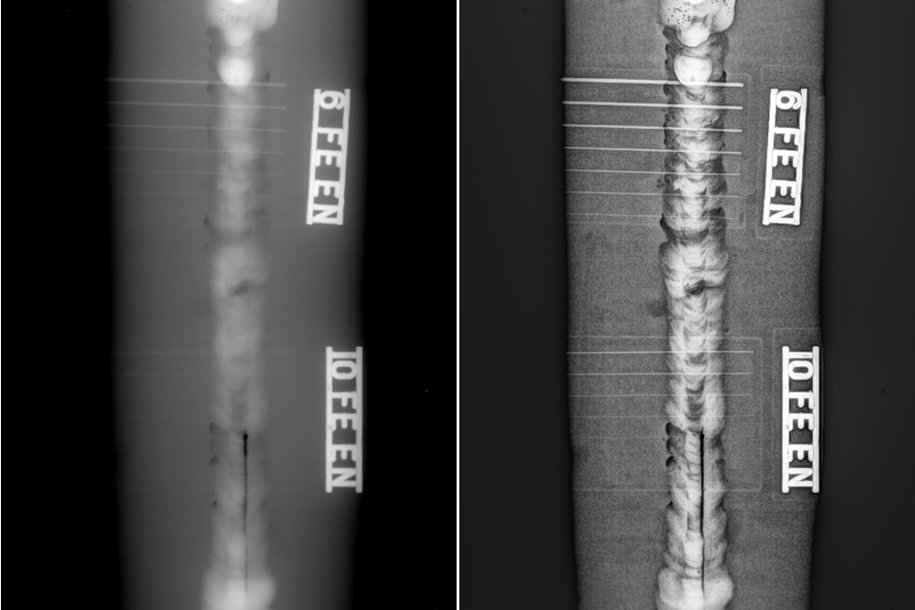

The highest radiographic inspection image quality available: high- and low-density details clearly visible in one crisp image

- FLASH! uses innovative, proven and leading image processing technology to ensure the highest possible image quality, every time

- With a single click, layered images are automatically processed and clarified, for easier reading and more confident results

- FLASH! automatically and quickly combines details from both high- and low-density areas into one HD image, with no manual adjustments required

- Even the most hidden, previously invisible faults become illuminated thanks to patented, next-gen technology which automatically adjusts to variations

- FLASH! works as a layer on top of the original image, without altering raw radiographic inspection data or the measurements made

Features

With the right inspection technology, you can see even the smallest details in crisp clarity, ensuring assets remain functioning at the highest productivity level

- Excellent, consistent image quality across all Waygate Technologies X-ray inspection and CT systems as well as CR and DR platforms

- Optimal rendering of all relevant imaging data, optimized for the human eye

- Robust image processing against variations (density, geometry, radiation quality, exposure settings, etc.)

- Smooth workflow at the operator and reviewer/verification levels

- Compatibility on all Field-radiography systems (DR, CR) as well as X-ray inspection systems

- DICONDE-compliant

Applications

FLASH! intelligent image processing has been proven globally; now let us prove it to you

- Aerospace

- Power Generation

- Automotive

- Oil & Gas

- Excellent, consistent image quality across all Waygate Technologies X-ray inspection and CT systems as well as CR and DR platforms

- High contrast even at lower dose

- Optimal rendering of all relevant imaging data, optimized for the human eye

- Robust image processing against variations (density, geometry, radiation quality, exposure settings, etc.)

- Smooth workflow at the operator and reviewer/verification levels

- Compatibility on all Field-radiography systems (DR, CR) as well as X-ray inspection systems.

- Now comes standard on all Waygate Technologies software platforms

- Three versions:

- FLASH! (for general use)

- FLASH! Electronics (optimized for Electronics inspection, X-ray inspection systems only)

- FLASH! OG (optimized for Oil & Gas)

FLASH! is DICONDE*-compliant.

* Digital Imaging and Communication in Nondestructive Evaluation (DICONDE): a global ASTM Standard for handling, storing and sharing image data and inspection information between DICONDE-compliant systems.