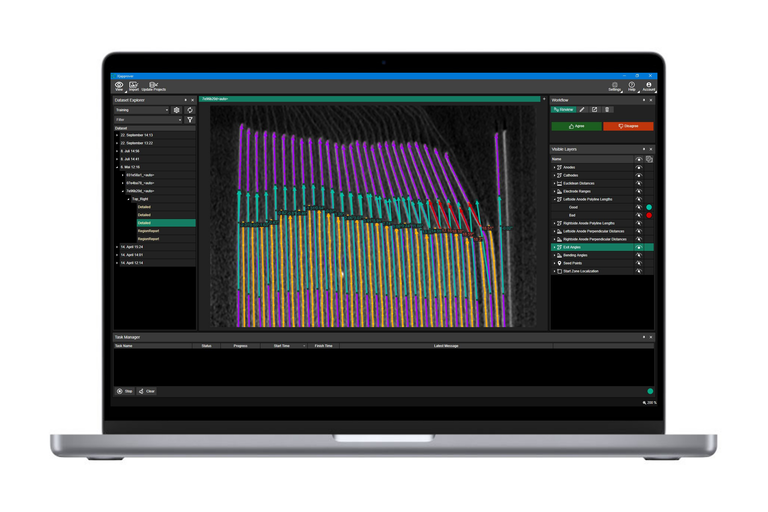

X|approver

Software for automating your defect analysis workflow

Industrial companies are scampering ways to increase inspection automation to deal with a wide range of new technologies and processes. A key area for automation lies in finding defects automatically during inspections to gain speed and improve the quality of the inspected objects. Waygate Technologies combines its comprehensive expertise in X-ray and CT inspection systems with latest artificial intelligence (AI) machine learning software, to find defects automatically and reliably for a variety of industrial sector components from castings to electronics and batteries.

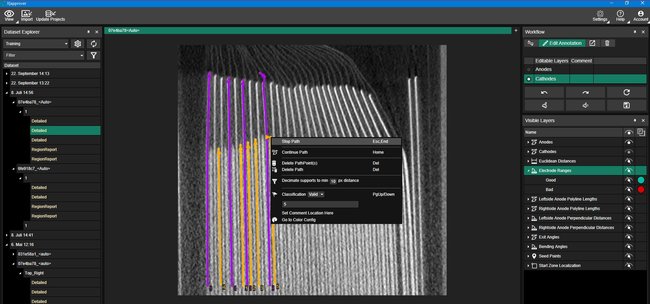

With X|approver Waygate Technologies offers an AI-based on-premises ADR software (Automated Defect Recognition) with specific teachable algorithms to evaluate the quality of components for a wide range of parts and leverage automated detection of microstructural defects from CT images. The software provides specific feature analysis with ADR for pass/fail decisions and fully automated CT workflows.

ADR starts here

X|approver consists of the full and intuitive workflow management as well as a comprehensive ADR library running in the background of your production, delivering automatic decision making. On top of it reporting functions allow to identify potential negative trends in production at just a glance. Authorized operators can parametrize scanned samples (e.g. for highly accurate overhang issue detection), and the algorithms get more accurate over time.

The highly consistent defect analysis results can reduce the workload for highly qualified operators and thus helps companies become more operator independent.

AI X-ray & CT ADR solutions can be consumed with X|approver or InspectionWorks Analyzer cloud platform. Additionally, Speed|ADR for 3D casting, ADR for electronic solder joints and cracks, and Field Radiography assisted recognition software is available.

Highlights

Benefits

Powering reliable CT ADR evaluation with machine learning

- Power consistent evaluation with 5 to 10 times greater throughput

- Significant scrap reduction reduces costs dramatically

- Permit precise AI-powered automated decision for higher quality

- Software libraries continuously expanded

- 90% + reduction in operator time and in expert analysis time

Features

AI-based on-premises ADR software (Automated Defect Recognition) with specific teachable algorithms to evaluate the quality of components

- Teachable, built-in reporting, multi-user, and customizable color picker

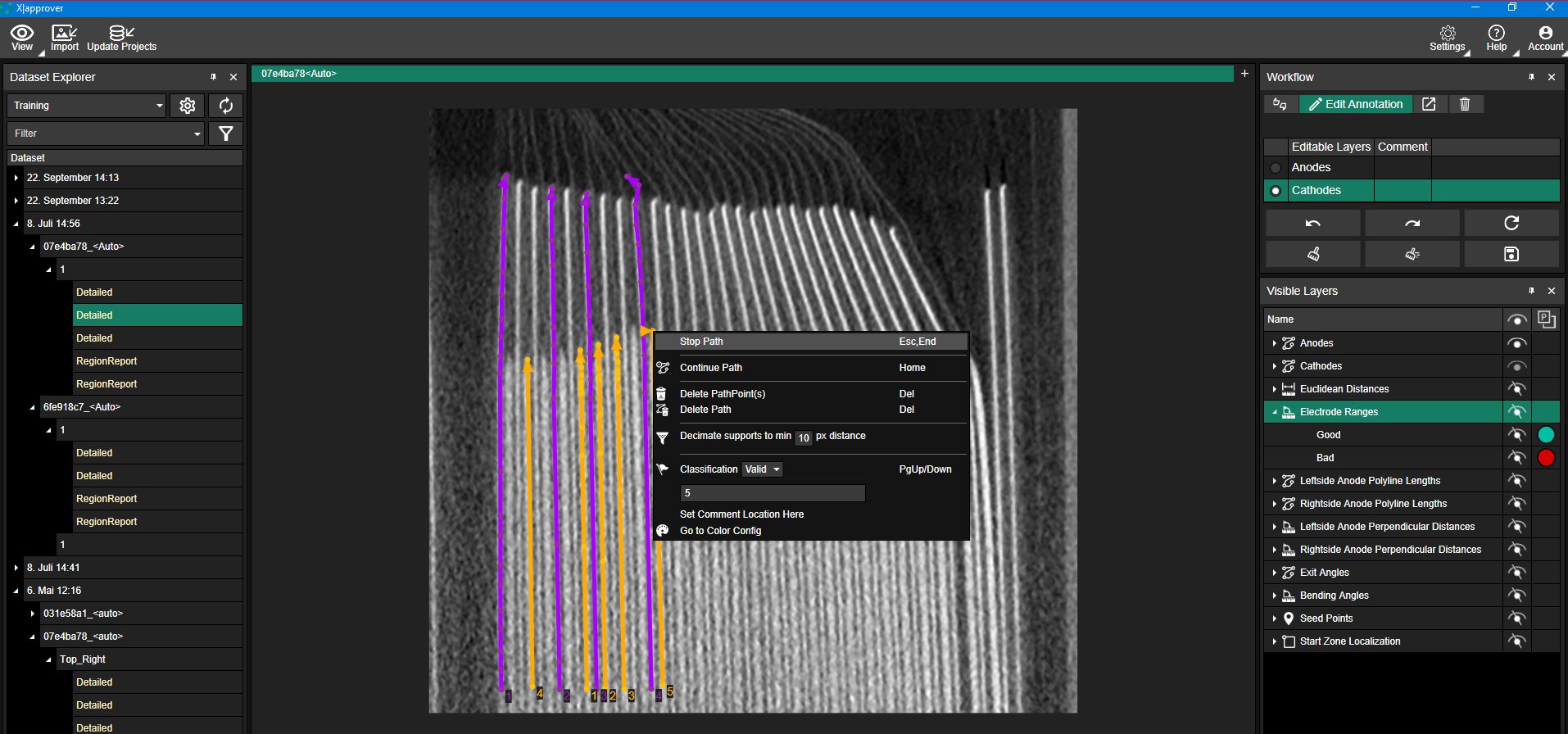

- Specific features for battery quality diagnoses such as precise electrode alignment measurements and support for multiple types of battery cells.

- Workflow features for the full machine-learning pipeline from image and 3D volume

- Annotations of ground truth from image sets acquired by users

- Ground truth preparation: inferences models are re-trained with the new information from the training data points

Applications

Waygate Technologies is building a very large library of trainable, AI and other algorithms for industrial X-ray ADR. Solutions exist or are in research for:

- Battery

- Castings (cracks, voids, foreign particles)

- Field radiography (wall thickness, aerospace cracks, particles)

- Electronics (PCBA joints, semiconductors, etc.)

X|approver is an on-premises ADR software for automating your defect analysis workflow. General features include teachable, built-in reporting, multi-user, and a customizable color picker. It also contains specific features for battery quality diagnoses such as precise electrode alignment measurements and support for multiple types of battery cells.

X|approver has workflow features for the full machine-learning pipeline from image and 3D volume important through the learning process. It supports annotations of ground truth from image sets acquired by users. Ground truth preparation can be done by users or Waygate Technologies consultants. Once ground truth is drawn for a particular structure or set of defects, the inferences models are re-trained with the new information from the training data points.

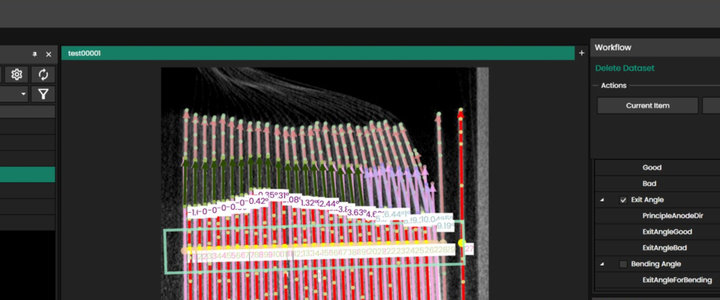

Battery technology is a specific focus at Waygate Technologies ADR (Advanced Defect Recognition) effort. During the manufacturing of lithium-ion battery electrodes, it is difficult to prevent certain types of defects, which affect the overall battery performance and lifespan.

The Waygate Technologies ADR Battery Solution running with X|approver is supporting different industries such as automotive (electric cars, electric trucks) and electronics (e.g. mobile phones). The software is agnostic to the types of cells having been adapted to cylindrical, prismatic, and pouch formats. It can be retrained and adjusted to fit the evolving nature of batteries technology as next-generation batteries enter the market.

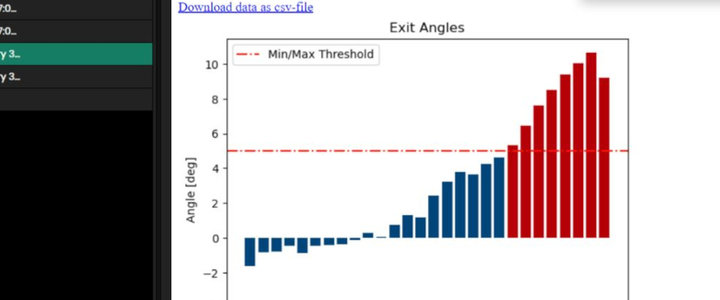

The Waygate Technologies ADR Battery Solution supports several different defects and features for analyzing battery issues. Firstly, the solution handles checking cathode and anodes positioning and length. Next, it calculates using ML overhang exit angle for the highest cathode length neighbor relation and bending angles and spacing. Lastly, it determines if electrode range are within adequate tolerances for high performing battery demands. The volumetric registration running at backend aligns CT volumes to aid the machine learning in achieving high accuracy scores and thus producing excellent analysis results.