Our visual inspection systems solutions

Access hard-to-reach areas and perform inspections with confidence using Waygate Technologies’ advanced visual inspection systems. Our remote visual inspection (RVI) solutions deliver precise, real-time results, helping you make informed decisions quickly and effectively.

Innovative Real3D measurement technologies

Achieve unparalleled precision with Waygate Technologies’ Real3D™ measurement technology. Our advanced visual inspection systems allow inspectors to capture, map, and measure in 3D, ensuring more accurate data collection and analysis. Real3D™ provides an interactive, fully-surfaced 3D point cloud, allowing for superior measurement accuracy, even in complex conditions. With features like TrueSight™ you can confidently assess hard-to-reach areas and make informed decisions faster. Waygate Technologies’ RVI solutions ensure you stay ahead of safety and efficiency demands, meeting the toughest industry standards.

Services that support your needs

We offer comprehensive remote visual inspection services to ensure your equipment is always operational. From rental and repair programs to advanced training through Waygate Inspection Academy, we support your inspection needs to minimize downtime and enhance productivity.

Comprehensive RVI for your needs

In industries like aerospace, oil and gas, and power generation, reliable remote visual inspection (RVI) is essential for preventing costly failures and ensuring safety. Waygate Technologies offers a full range of RVI tools, including video borescopes, pan-tilt-zoom cameras, and robotic inspection systems, designed to meet the challenges of any inspection environment.

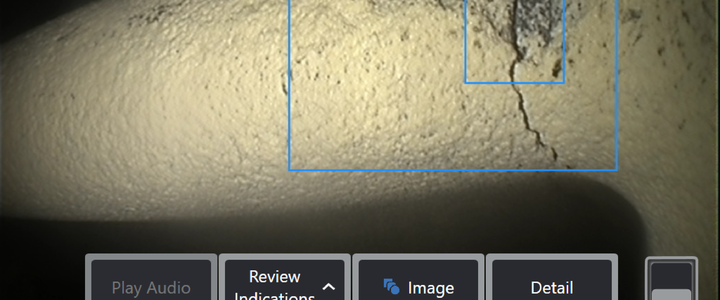

High-precision defect detection with Real3D™ technology

Our advanced video borescopes feature Real3D™ measurement technology, helping you achieve accurate measurements in hard-to-reach areas. With features like TrueSight™ and DarkBoost™, inspectors can capture high-quality images even in low- light conditions, ensuring that critical defects are detected with confidence.

Durable and versatile visual inspection equipment

For large-scale inspections, our pan-tilt-zoom cameras offer unmatched durability and versatility, with interchangeable zoom heads and rugged construction designed for remote use in industrial settings. Our robotic inspection solutions further enhance precision by automating inspections in confined or hazardous environments, reducing downtime and improving safety.

Resources that help maximize uptime and efficiency

In addition to our comprehensive support and 24/7 technical assistance, Waygate Technologies offers a range of online resources, including product demonstrations, webinars, and expert insights. Our latest video borescope, the Everest Mentor Flex, exemplifies how our solutions combine durability and precision to streamline your operations. Reduce downtime, enhance inspection accuracy, and stay ahead of production demands, with Waygate technologies support..

Discover Our Products

Where remote visual inspections matter

Aerospace RVI

Power generation

Oil and Gas

Why choose Waygate Technologies

Our combination of cutting-edge image quality and advanced 3D measurement technologies revolutionizes the inspection process, delivering greater accuracy, speed, and efficiency. These innovations allow inspectors to achieve superior clarity, enabling faster, more informed decisions:

Over 120 Years of Experience:

With a deep-rooted history in Non-Destructive Testing (NDT), Waygate Technologies has over a century of experience in delivering reliable, high-quality inspection solutions across multiple industries.

Revolutionizing Remote Visual Inspections (RVI)

We transformed the industry with the introduction of 3D Phase Measurement (3DPM) technology over a decade ago, and we continue to set new standards with advancements in AI, Automated Defect Recognition (ADR), and strategic partnerships with industry leaders such as GE, Rolls-Royce, and Rhinestahl. Our innovative solutions empower inspectors to detect and assess critical indicators like cracks, corrosion, and wear with remarkable precision, even at extended distances

Significant Efficiency Gains

Enhanced detection and workflow automation reduce inspection times by up to 25%, enabling faster assessments of critical components such as gas turbines, boiler tubes, and column towers.

Advanced Customization for Complex Inspections

Our Mentor Visual iQ VideoProbe with HD capability offers fully surfaced point cloud analysis and long-range measurement, allowing users to scan larger areas and make precise measurements in challenging environments. These tools ensure faster, more reliable assessments across industries.

Case studies and partnerships

Rolls-Royce customer story

Petrobot

General Electric

Gas turbine inspection

Remote visual inspection (RVI) plays a critical role in maintaining the safety, efficiency, and performance of equipment across various industries. It allows operators to assess the condition of hard-to-reach or hazardous areas without direct contact, ensuring that inspections can be performed in environments where manual inspection would pose risks to personnel or require significant downtime. RVI also helps in detecting potential issues early, reducing the likelihood of costly failures or accidents. By enabling inspections in confined or dangerous spaces, such as within industrial pipelines or turbines, RVI improves overall operational efficiency and enhances the longevity of assets. Furthermore, advanced remote visual inspection tools provide high-quality imaging and precise data, allowing for more informed decision-making in maintenance and repair strategies.

The effectiveness of remote visual inspection (RVI) is significantly enhanced by advanced imaging technologies, including high-resolution cameras, 3D scanning, and infrared sensors. These tools provide detailed visuals and data, even in challenging environments, ensuring accurate assessments. Flexible RVI tools like robotic systems further improve access to confined or hazardous areas, enabling comprehensive inspections that would be difficult or unsafe for human

inspectors.

Real-time data transmission and remote monitoring also boost RVI's effectiveness, allowing for immediate decision-making and collaboration with remote experts. Additionally, proper training and expertise in using RVI equipment are essential to ensure precision and reduce human error, leading to more efficient and thorough inspections.

Using remote visual inspection (RVI) systems or equipment involves a series of steps to ensure effective and accurate inspections. First, operators should conduct a pre-inspection check, which includes assessing the area to be inspected and choosing the appropriate RVI equipment, such as borescopes, drones, or robotic crawlers, depending on the environment and the inspection requirements. Ensuring that all devices are properly calibrated and functioning is also crucial for accurate data collection. Once the equipment is ready, the operator carefully navigates the RVI tools into the target area, using either manual control or automated systems, depending on the equipment.

Advanced systems often feature real-time video feeds or data collection that allow the operator to monitor the inspection process and make adjustments as needed. After completing the inspection, the collected visuals or data are reviewed to identify any issues or areas of concern. Proper training and familiarity with the equipment are essential for handling it effectively and maximizing the quality of the inspection.

Other services

Industrial radiography and CT

NDT software

Industrial ultrasonic testing