Industrial Computed Tomography

Delivering state-of-the-art industrial CT scanning services and solutions for aviation, automotive, electronics, additive and industrial manufacturing sectors through Waygate Technologies, a Baker Hughes business.

Versatile Industrial CT Scanning Capabilities

Our state-of-the-art industrial computed tomography (CT) portfolio addresses the full spectrum of industrial inspection challenges, from microscopic electronic components to large metal castings:

- Ultra-precise scanning for small components with submicron detection

- High-absorption capability for metal castings and aviation components (cylinder heads or aviation fan blades)

- Flexible research-grade systems for specialized investigations

- Production-optimized inline and at-line CT for high-volume manufacturing

Driving measurable results

Harness the power of advanced CT technology to revolutionize your quality control operations. Our innovative solutions combine cutting-edge hardware with intelligent automation to dramatically reduce inspection times while maintaining superior accuracy:

- Reduce inspection times by up to 97% (from 60 minutes to 1.5 minutes)

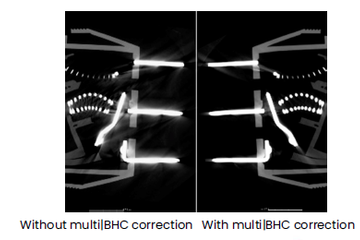

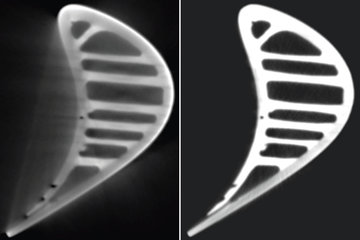

- Artifact-free precision increases sensor sensitivity, doubling CT speed/resolution.

- Streamline operations with fully automated workflows

- Achieve consistent, reproducible 3D product information

Industrial X-Ray & Computed Tomography Solutions

X-ray and CT systems and Detectors

Waygate Technologies, a Baker Hughes business, provides 2D and 3D computed tomography (CT) services across industries that include aviation, automotive, electronics, additive and industrial manufacturing. Our non-destructive 3D metrology is enabling high-speed 3D process control to ensure greater safety, quality, and efficiency.

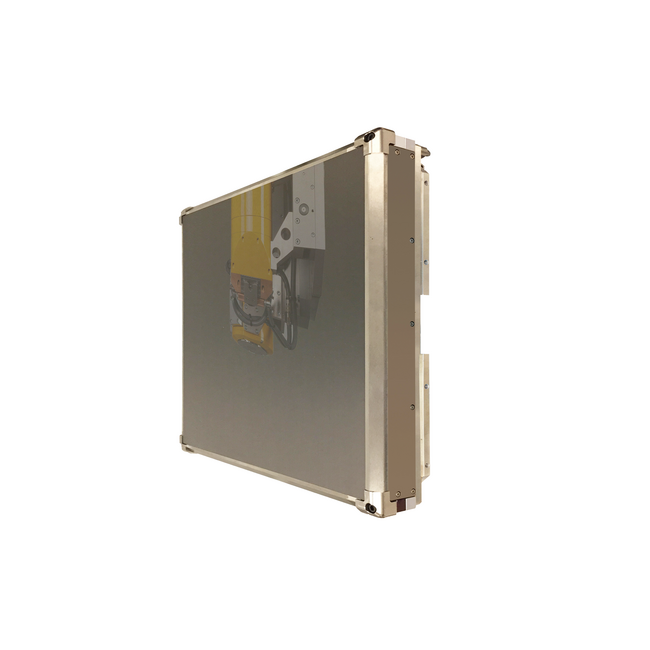

The Dynamic 41|200 belongs to Waygate Technologies’ next generation industrial X-ray flat panel X-ray detector platform. Waygate’s proprietary EnduranceTM CSI scintillator offers superior resolution and brightness compared to conventional GadOx or other powder based scintillators.

The Dynamic 41|100 is the first product in Waygate Technologies next generation industrial X-ray flat panel X-ray detector platform. At approximately 410 x 410 mm² (16"x16") detection area and 100 µm pixel size, it combines superior image quality with improved detection speed

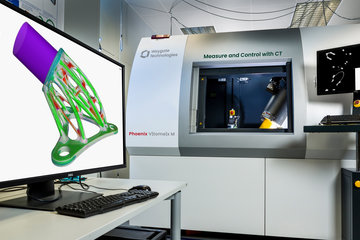

Phoenix X-ray - Advanced 2D and 3D CT Solutions

Phoenix X-Ray is Waygate Technologies' comprehensive product line that delivers advanced industrial radiography and CT systems solutions across an extensive range of inspection applications. The Phoenix portfolio encompasses everything from high-speed CT scanners and advanced detector systems to specialized MicroCT and NanoCT systems, offering unprecedented precision down to 0.2 μm resolution.

Our technology suite includes both mini focus and micro focus computed tomography systems, complemented by sophisticated 3D metrology scanners that ensure precise dimensional measurements.

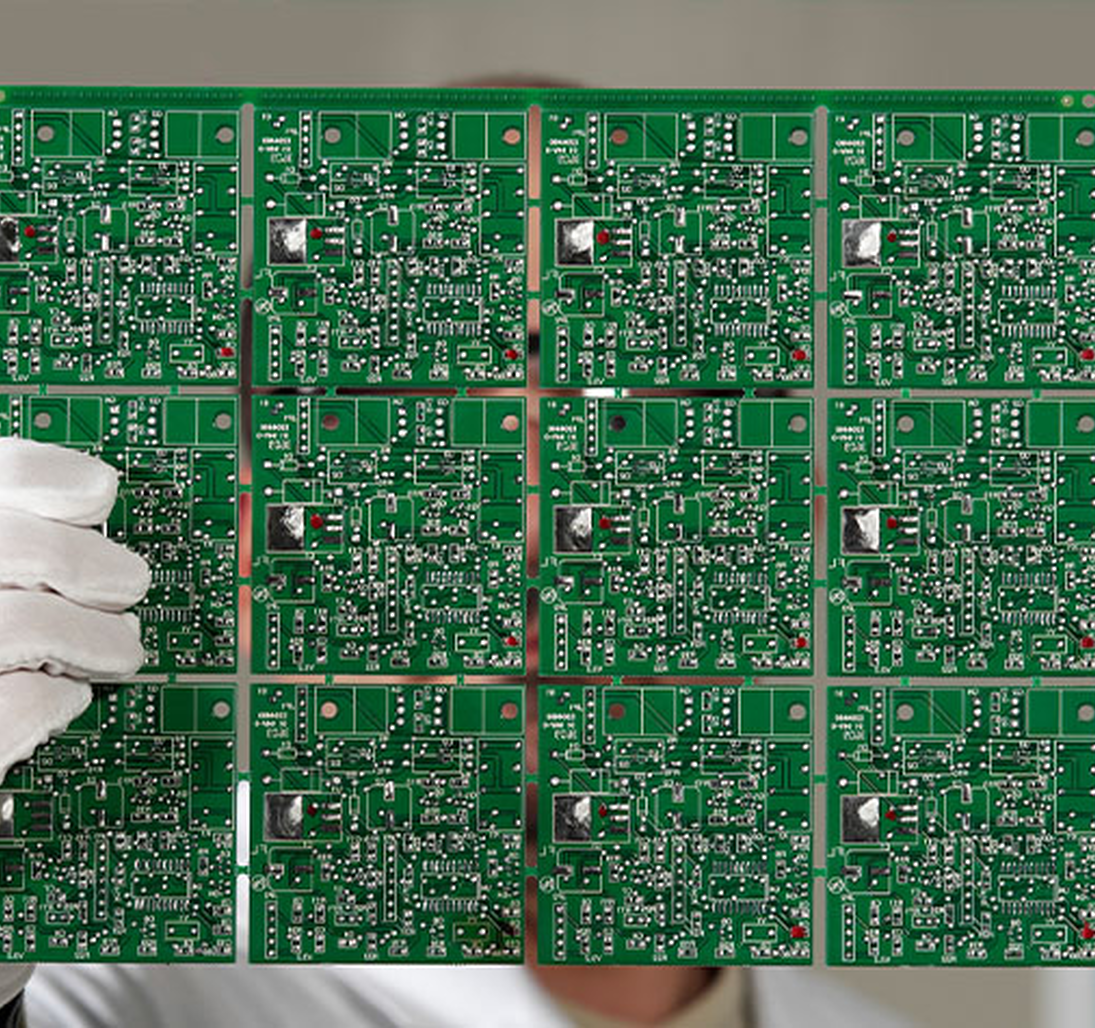

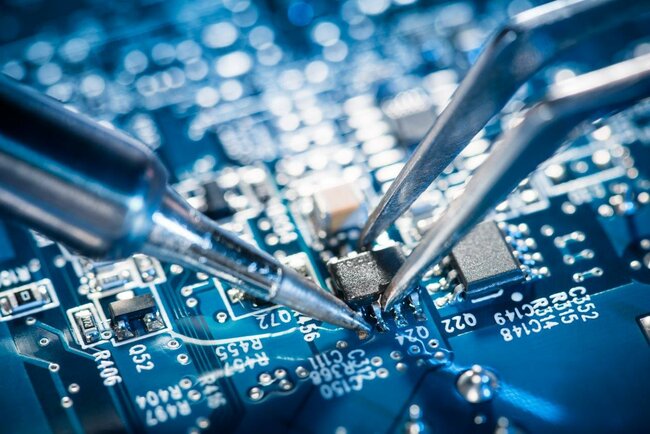

Electronics Testing Solutions

Waygate Technologies family of high-performance industrial x-ray inspection machines and intuitive software tools introduce a new industry standard for efficient, reliable and non-destructive testing (NDT) live inspections.

Extreme high positioning accuracy make our systems the effective and reliable solution for a wide spectrum of 2D and 3D offline inspection tasks: R&D, failure analysis, process and quality control.

Microscopic electrical components are the hidden heroes in millions of different devices across a wide spectrum of industries. Though small, these components play an important role in the healthy functionality of everything from airplanes to smartphones. Ensuring the integrity of electrical components via industrial x-ray electronics inspection is vitally important not only for maintaining brand reputation – but also for public reliability and safety.

In an era where technology is integral to every aspect of modern life, batteries have become the silent heroes powering our world. From electric vehicles to portable electronics and renewable energy storage, batteries are the heart of innovation. At Waygate Technologies, we understand the pivotal role, batteries play and the growing importance of ensuring their safety, efficiency, and longevity.

Global Industrial X-ray 2D and 3D CT Scanning Services

At our global Customer Solution Centers (CSC), we provide you on-demand use of our proven, state-of-the-art, non-destructive X-ray 2D and 3D Computed Tomography (CT) scanning inspection technologies and access to our staff of experienced experts.

You can access the most reliable industrial CT scanning and industrial radiography services for plastics, composites, castings, additively manufactured parts, ceramics, electronics, batteries and more.

Next to demos, in-depth customer trainings and problem solving consulting our global CSCs also offer on-demand inspection services with latest Waygate Technologies NDT equipment such as RVI, Ultrasound, 2D X-ray, and 3D Computed Tomography for failure analysis and dimensional metrology.

X-ray and CT Inspection Innovations

Waygate Technologies, formerly known as GE Inspection Technologies, is an industry leader in advanced Industrial Radiography and CT scanning solutions. Explore cutting edge innovations like planarCT, scatter|correct, speed|ADR and more.

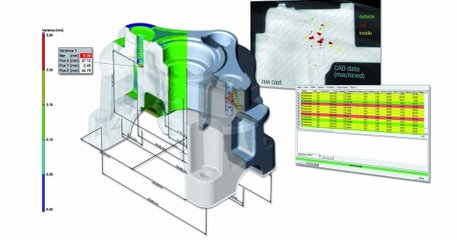

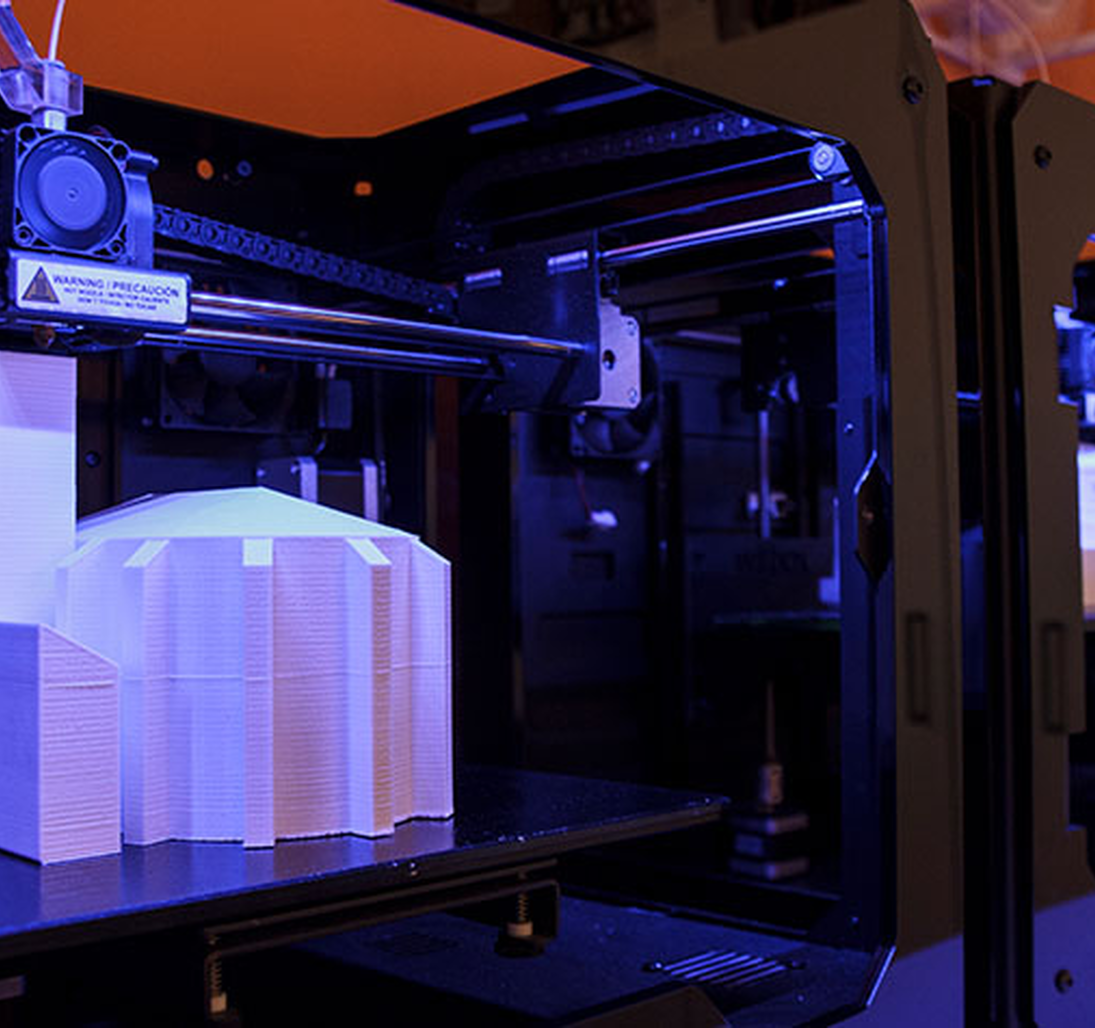

For production process control of complex and expensive components, Computed Tomography (CT) becomes the technology of choice for many inspection and metrology tasks, e.g. for automotive castings, aerospace turbine blades or 3D printed parts which by nature have hidden features.

As part of Waygate Technologies CT innovations bundle combined with Scatter|correct and latest Dynamic 41 detector technology, the new Waygate proprietary High-flux|target makes CT scanning more efficient to allow even robot based fully automated high productivity mass CT inspection on the production floor, e.g. in casting industry or additive manufacturing.

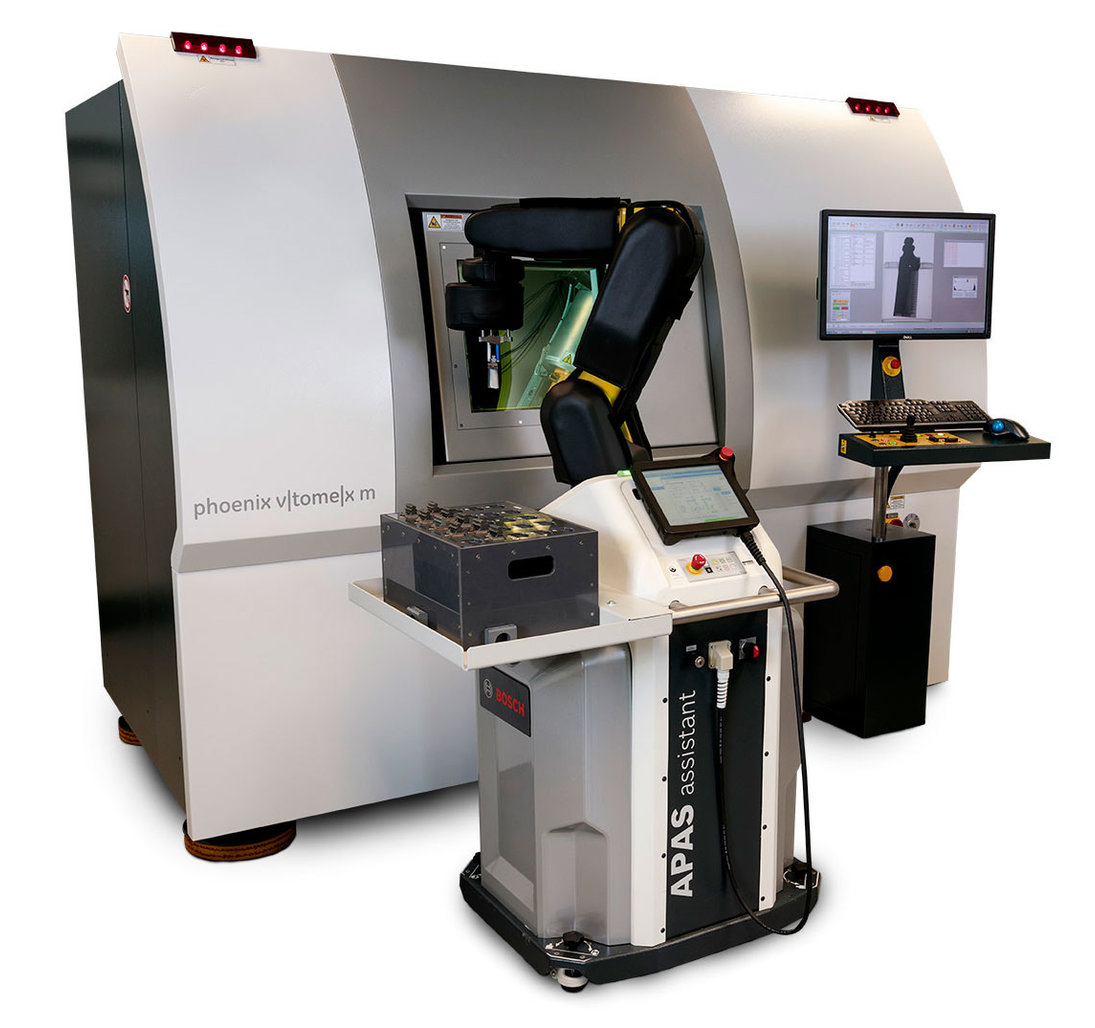

Exclusively available in Waygate Technologies' Phoenix V|tome|x premium performance CT system family, True|position and Easy|calib technology expand the measurement positions with specified accuracy to all positions which can be verified with the innovative patented Ruby|plate calibration phantom.

Why choose Waygate Technologies

At Waygate Technologies, we are pioneering the future of industrial computed tomography with innovative solutions that combine unprecedented speed, precision, and automation. Our advanced industrial CT systems and dedication to technological excellence make us the preferred choice for industries demanding the highest standards in quality control and inspection. From aerospace components to automotive parts, our CT solutions deliver exceptional results that ensure safety, quality, and productivity across all applications. Here's what sets us apart:

Revolutionary Scanning Speed

Our exclusive innovations like Scatter|correct 2.0 and Dynamic 41 digital detector technology have transformed traditional CT scanning, reducing inspection times from hours to just minutes while maintaining superior image quality.

Unmatched Precision and Flexibility

With capabilities ranging from submicron detail detection to large-scale industrial scanning, our systems offer versatile solutions for every inspection need. Our advanced technologies like High-flux|target and Multi|bhc ensure artifact-free precision and superior image quality.

Industry-Leading Automation

Our comprehensive automation features, including Sample|changer and Filter|changer technologies, enable 24/7 operation and up to 100% production control, significantly reducing operational costs and human error.

Industrial CT (Computed Tomography) is a non-destructive testing and measurement technology that uses X-rays to create detailed 3D images of an object's internal and external features:

Industrial CT works by taking hundreds or thousands of 2D X-ray images of an object from different angles, then using computer processing to construct a detailed 3D model. This process reveals:

• Internal structures and geometries

• Material variations and densities

• Defects, voids, or cracks

• Precise dimensional measurements

Key applications include:

Manufacturing Quality Control - Inspecting parts for internal defects, measuring wall thickness, and verifying complex internal geometries.

Reverse Engineering - Creating detailed 3D models of existing parts, including internal features that can't be measured with traditional methods.

Failure Analysis - Examining failed components to understand root causes without destroying the evidence.

Assembly Verification - Checking assembled products for proper component placement and potential interference.

Unlike medical CT scanners, industrial CT systems:

• Use higher energy X-rays to penetrate dense materials like metals

• Offer higher resolution (down to micrometers)

• Can handle larger and heavier objects

• Often provide more detailed measurement capabilities

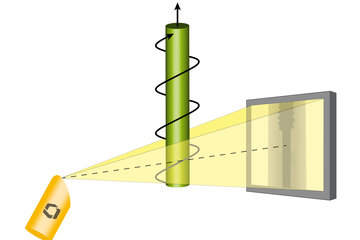

- X-ray Generation

- A powerful X-ray source generates a beam of X-rays

- The energy level is adjusted based on the material density and thickness being scanned

- Object Positioning

- The part is placed on a precision rotary table between the X-ray source and detector

- The table's position and movement are computer-controlled for precise positioning

- X-ray Penetration and Detection

- X-rays pass through the object

- Dense areas absorb more X-rays, while less dense areas allow more X-rays to pass through

- A digital detector panel captures the X-rays that pass through the object, creating a 2D projection image

- Rotation and Image Capture

- The part rotates through 360 degrees in small increments

- At each increment, a 2D X-ray image is captured

- Typically hundreds or thousands of 2D images are collected during one complete rotation

- Data Processing

- Specialized software processes all the 2D X-ray images

- Using complex algorithms, it reconstructs these images into a 3D volume

- The reconstruction creates a complete 3D model made up of voxels (3D pixels)

- Analysis and Measurement

- The 3D model can be sliced in any direction for internal viewing

- Software tools allow precise measurements of internal and external features

- Different materials can be distinguished based on density variations

- Defects, voids, or inclusions become visible in the 3D model

Key Technical Parameters:

- X-ray power (typically 100-450 kV for industrial applications)

- Detector resolution and size

- Geometric magnification (determined by source-to-object and object-to-detector distances)

- Number of projections (2D images) taken

- Reconstruction algorithms used