Phoenix V|tome|x M300

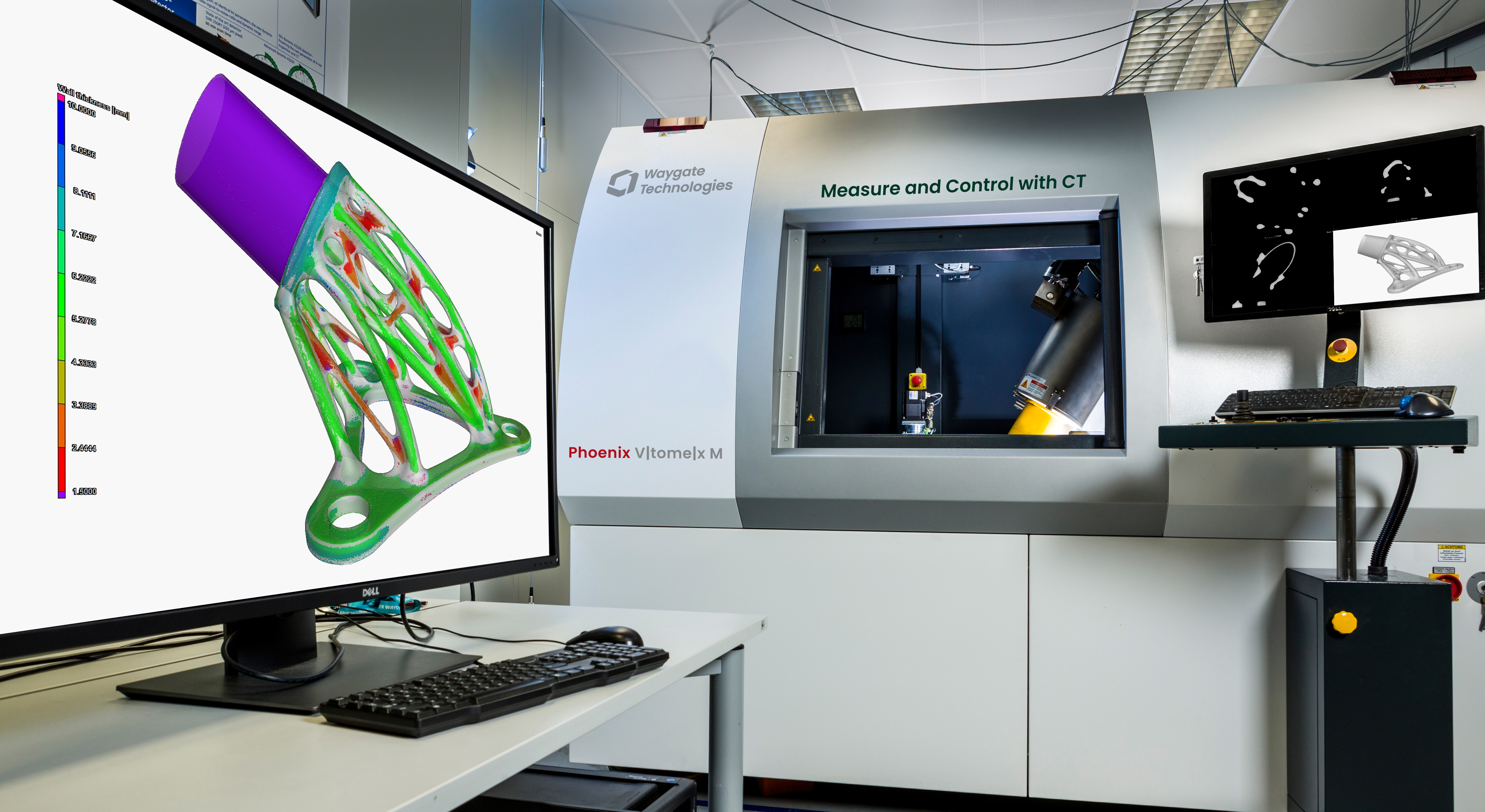

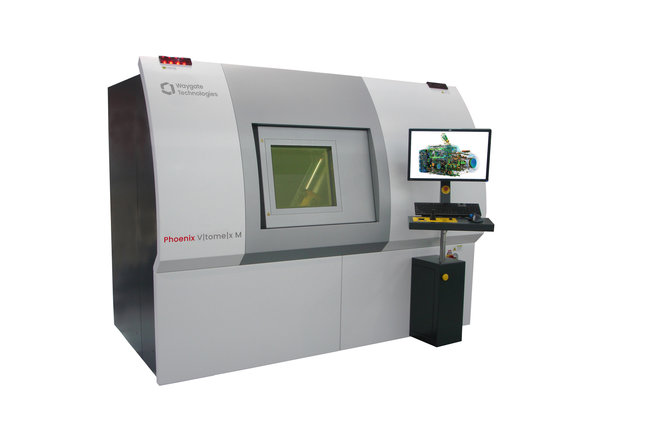

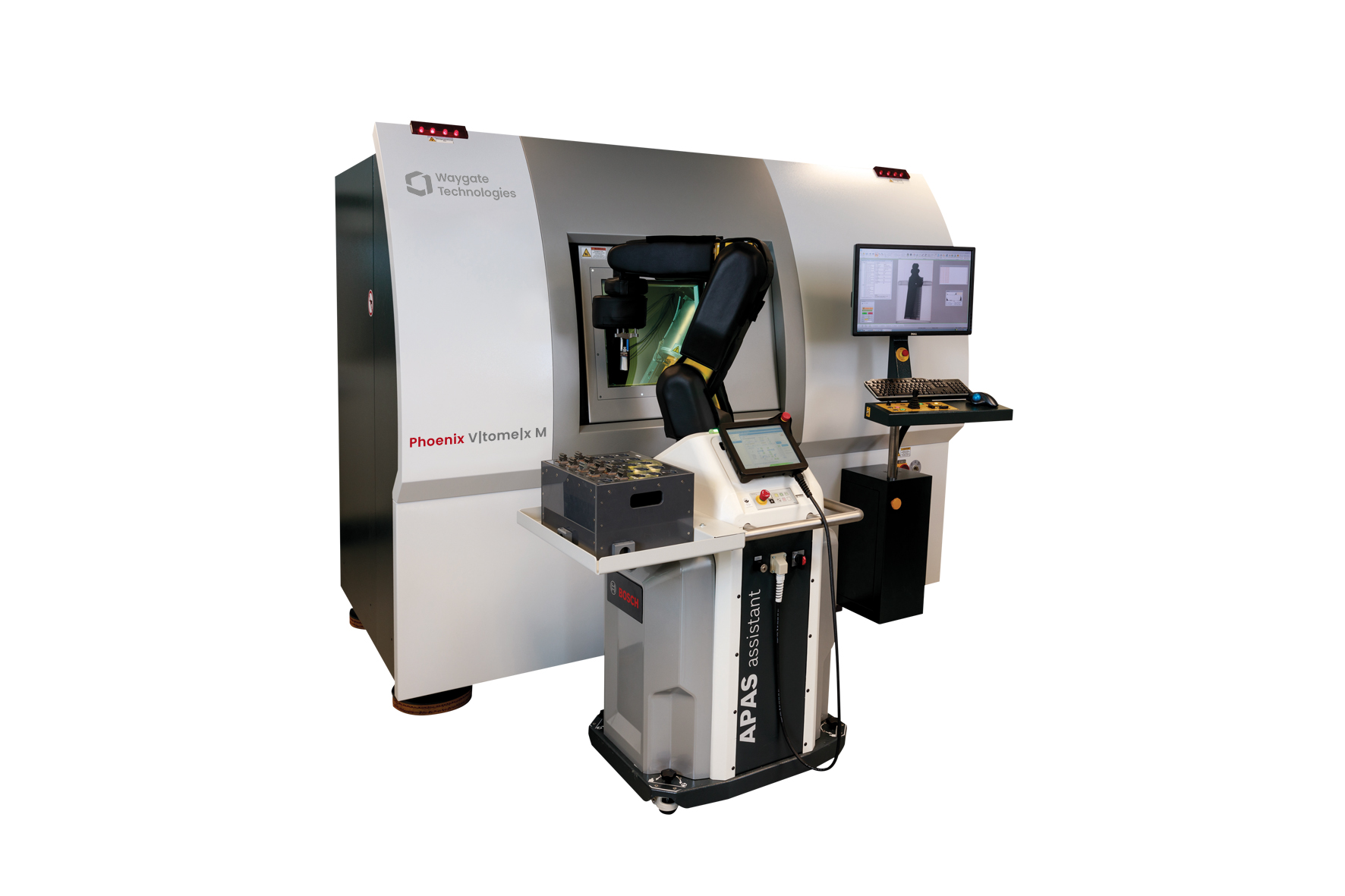

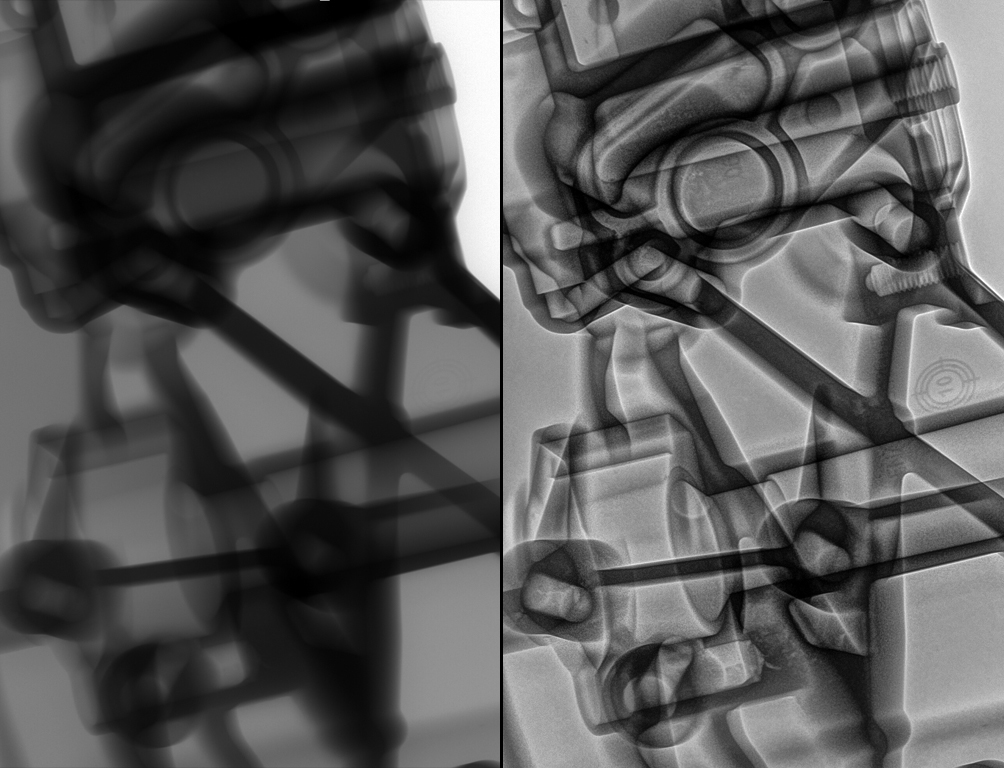

The Phoenix V|tome|x M is Waygate Technologies most versatile and precise X-ray microfocus CT cabinet system for 3D metrology and analysis.

This highly productive Dual|tube scanner with its 300 kV microfocus and optional 180 kV nanofocus X-ray tubes delivers improved accuracy at unprecedented speeds—helping you dramatically optimize your lab research results and production quality processes to meet today’s und future increasing demands.

Our powerful industrial computer tomography (CT) system, designed for 3D metrology and analysis, provides industry-leading magnification at 300 kV. It is the world’s first microCT scanner with Scatter|correct technology, to automatically remove scatter artifacts for higher image quality. With a variety of exclusive high performance detectors and proprietary premium CT technologies, the Phoenix V|tome|x M revolutionizes CT inspection and 3D metrology - delivering faster scans and higher throughputs without compromising image quality and measurement precision.

Highlights

Benefits

CT Scanning & Metrology at Higher Accuracy, Higher Speeds

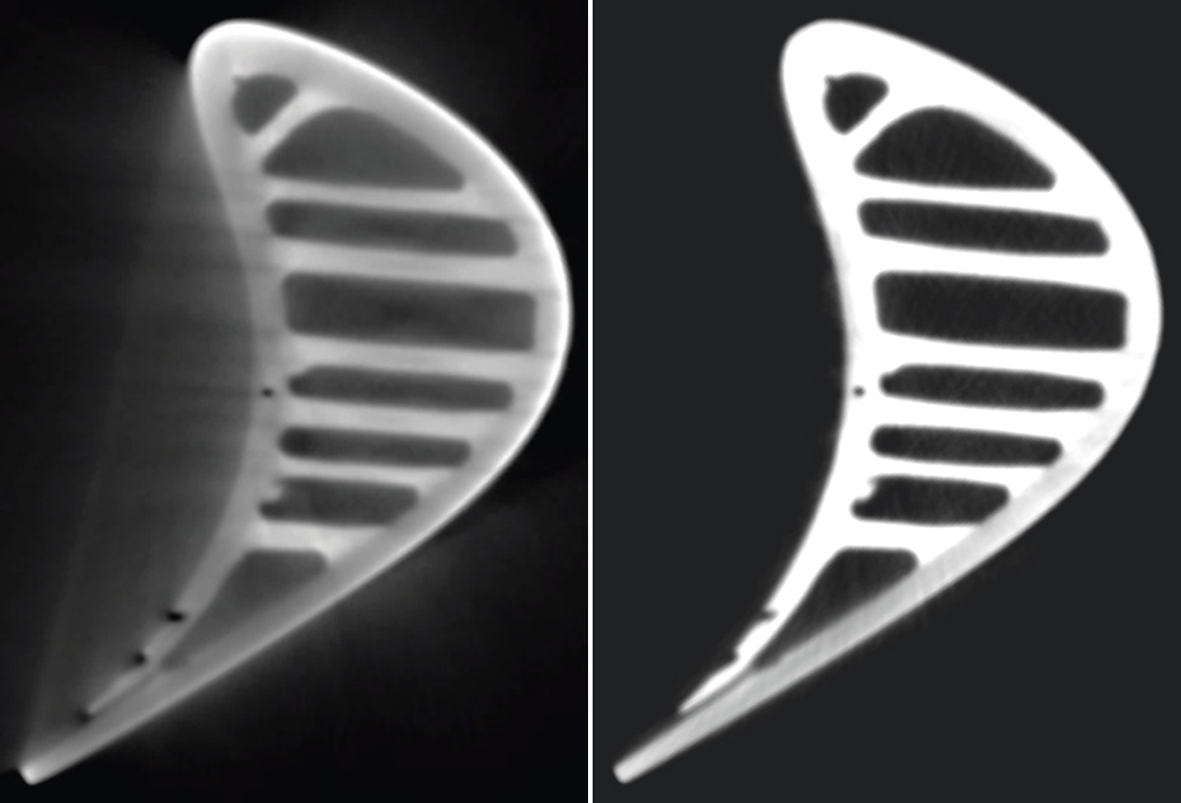

- High-quality images via Scatter|correct technology

- High-speed scans thanks to exclusive detectors technology and patented

- Outstanding reliable metrology precision

- Highest versatility due to optional 300 kV micro- and 180 kV nanofokus Dual|tube setup

- Industry-leading microfocus magnification at 300 kV

Applications

The Phoenix V|tome|x M300 system covers an extremely wide range of application capabilities:

- Internal defect analysis

- 3D quantitative porosity analysis

- Assembly control

- Materials structure analysis for small high-absorbing castings

- Highest precision nanoCT of small or low absorbing samples

- Research: 3D printing, composites, battery cells and modules, ceramics, medical industry

- Precision 3D metrology

- CAD Data nom/act comparison

Tubo radiogeno microfocus da 300 kV / 500 W - appositamente ottimizzato per le applicazioni TC, opzionalmente in combinazione con un tubo radiogeno nanofocus ad alta potenza da 180 kV/20 W per scansioni di massima precisione di campioni più piccoli e a basso assorbimento

La durata del filamento è fino a 10 volte superiore, in modo da garantire stabilità a lungo termine e massimizzare l'efficienza del sistema grazie al filamento a lunga durata (opzionale).

L'esclusiva tecnologia brevettata da Waygate Technologies, Scatter|correzione, consente di eseguire scansioni TC altamente precise di campioni ad alta dispersione di radiazioni, con la qualità d'immagine superiore della TC a ventaglio e con una produttività fino a cento volte superiore rispetto alla TC a cono.

Raddoppio della risoluzione TC alla stessa velocità o raddoppio della produttività allo stesso livello di qualità dei rivelatori DXR con passo da 200 µm. Rispetto ai rilevatori a 16 bit, la tecnologia ottimizzata a 14 bit offre la massima efficienza con una gamma dinamica di 10000:1, consentendo di risparmiare tempo nell'uso e di generare meno rumore nell'immagine.

Scansione di parti ancora più grandi con un volume di scansione fino a circa il 70% maggiore

Definizione di un asse di rotazione della scansione virtuale per facilitare la regolazione della scansione e la flessibilità delle scansioni TC ROI

Lo strumento Multipli|bhc corregge gli artefatti da striature che tipicamente si presentano come bande scure multiple posizionate tra aree dense in campioni multimateriale.

Filtro adattativo per la correzione della dispersione che offre una qualità d'immagine impareggiabile, riducendo in modo significativo gli artefatti causati dalla riduzione dei valori di grigio in set di dati TC con campioni ad alto assorbimento.

Questo supporto, che può essere rimosso senza difficoltà, consente di cambiare automaticamente i diversi campioni.

In combinazione con il Campione|scambiatore, il sistema Filtro|scambiatore opzionale consente di eseguire scansioni TC miste in batch.

Rendete completamente automatica l'acquisizione dei dati, l'elaborazione dei volumi e la relativa valutazione senza difficoltà.

Servizi mondiali di scansione industriale a raggi X 2D e 3D di Waygate Technologies

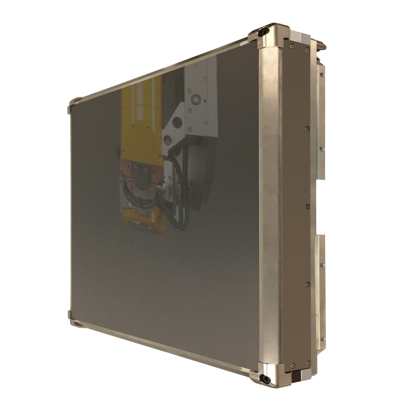

The Phoenix V|tome|x M comes standard with our exclusive 4 MP Dynamic 41|200 next-generation photodiode design industrial X-ray detector. It provides 10x increased sensitivity relative to the state of the art 200µm pixel-size DXR detectors producing a 2-3x cycle time increase without image quality impact, making inspections and measurements more efficient and productive.

As a premium option, the 100µm / 16 MP Dynamic 41|100 detector provides 2x the resolution increase without impacting cycle times. Detection of 2x smaller defects without an increase of geometric magnification allows for the imaging of large objects at higher resolutions.

Dynamic 41 digital detector technology means you get up to 2-3x faster CT scans or doubled resolution.

Advanced Scatter|correct technology automatically removes scatter artifacts for artifact-free precision CT results on the quality level of fan-beam CT scanned several hundred times faster with advanced cone-beam CT.

Our proprietary High-flux|target allows for higher power on a smaller focal spot, so you can cut scan time in half.

Boost your CT scanning performance with a fully automated, robot-based workflow and 3D analysis in real-time.

Backed by our proprietary technology and durable hardware, you can maintain safe and reliable operations while remaining in compliance.

By bringing your CT inspection right onto the factory floor or into the lab, you can unite manufacturing with quality control for greater reliability, speed, and efficiency.

Unique Dual|tube configurations enhance the flexibility. Depending on the inspection task, fast and easy change between the microfocus and nanofocus X-ray tube is possible just by a push of a button.

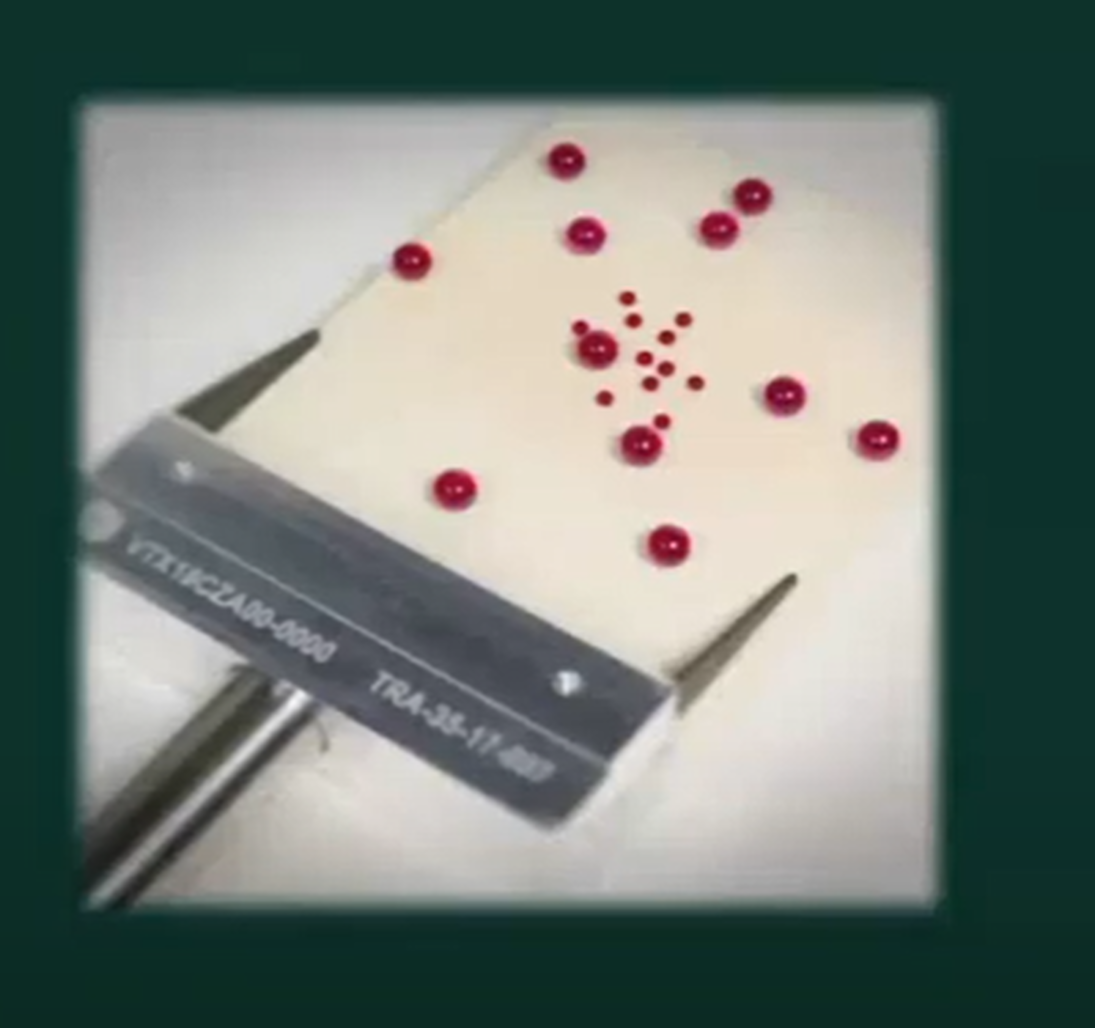

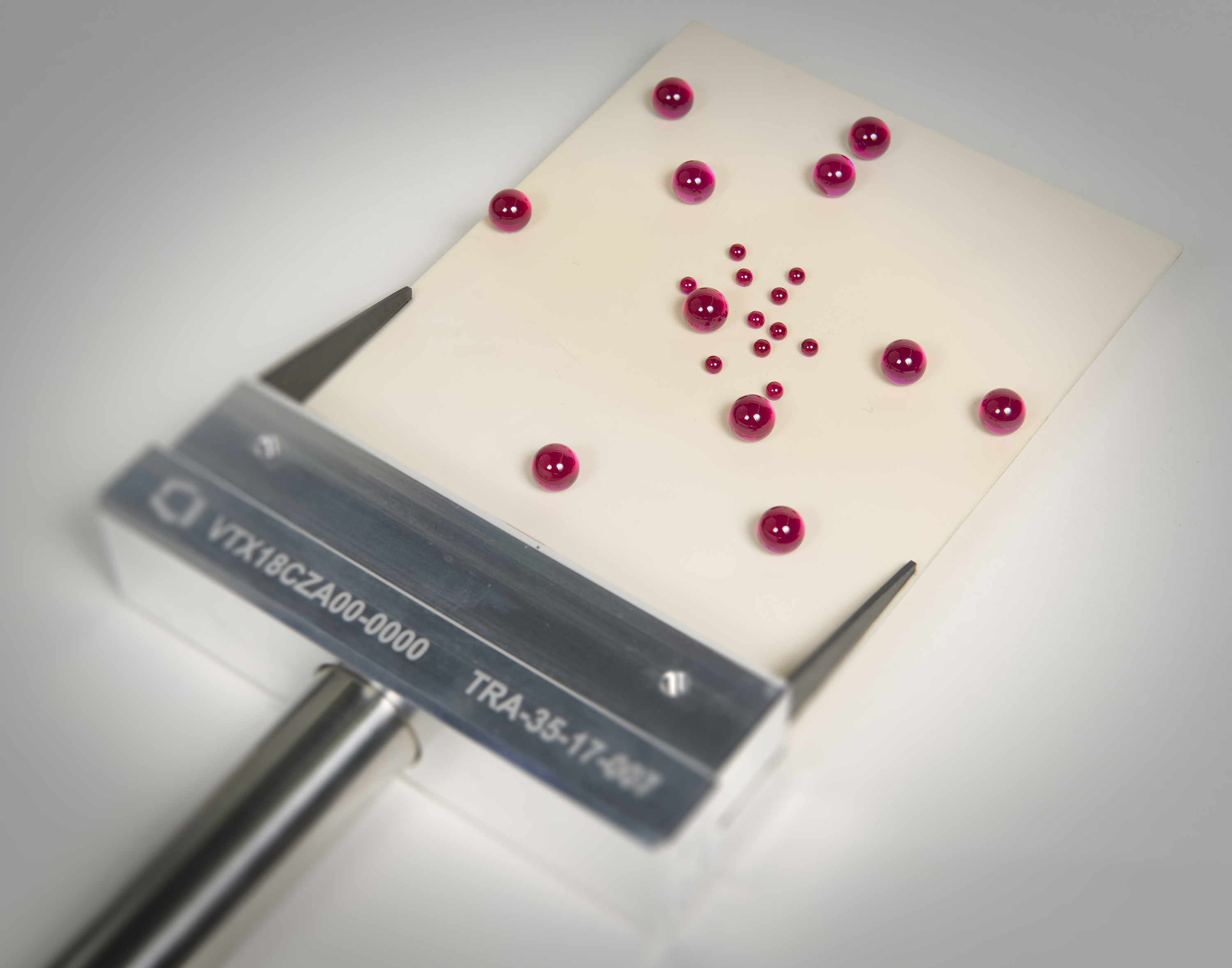

With Ruby|plate and True|position technology, the Phoenix V|tome|x M has a specified accuracy of SD ≤ (3.8 + L/100 mm) µm, referring to VDI 2630-1.3 guideline. For all other positions between the VDI positions, a remarkable accuracy of SD ≤ (5.5+ L/100 mm) µm can be reached.

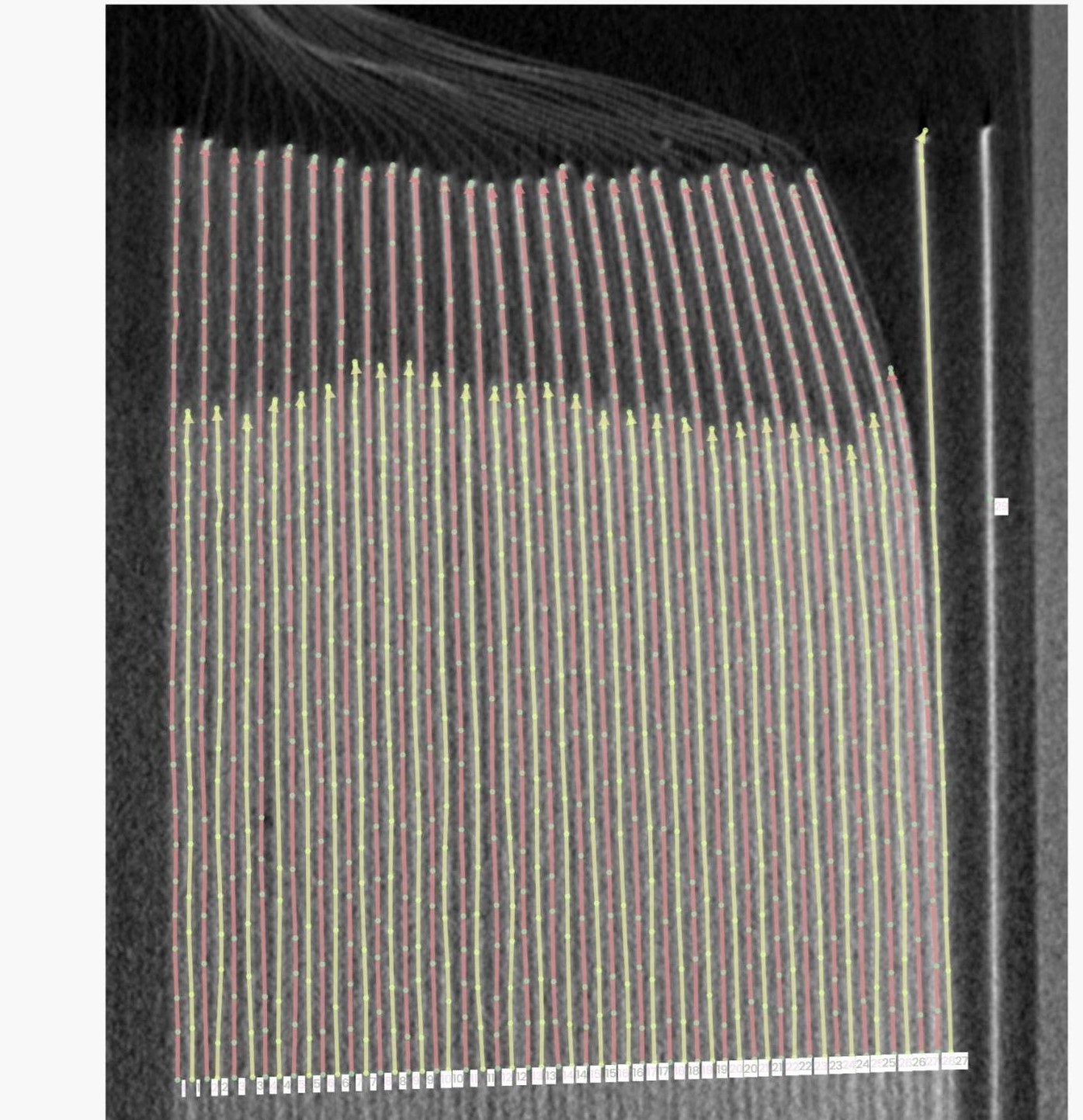

Proprietary machine learning (ML) based algorithms deliver exceptional Automated Defect Recognition (ADR) across various flaws for e.g. battery anode overhang analysis or typical casting defects. Our AI and data science based ADR library yields greater accuracy and enhanced ease of use compared to conventional ADR approaches, eliminating the need for expert parameterization skills.

Waygate Technologies offers X|approver, the next level and premium ADR platform consisting of the full and intuitive workflow management as well as a comprehensive ADR library running in the background of your production delivering automatic decision making. On top of it reporting functions are provided to see potential negative trends in production at a glance. Any authorized operator can parametrize scanned samples (e.g. for highly accurate overhang issue detection), and the algorithms get more accurate over time.

There is more information in an images acquired within a 2D application or slide taken from a CT scan visible for the human eye. The system includes Waygate Technologies X|act NDT inspection software with industry leading Flash!™ intelligent image processing technology unveil details that are not visible before. Users benefit from two versions:

- Flash! (for general NDT use such as casting inspection)

- Flash! Electronics (optimized for Electronics inspection)

Technical Specifications

Want to pimp your system? With our software- and hardware-upgrades, you can increase your quality and throughput. Have a look at your upgrade options by clicking here!

Up to 50 kg, depending on the application.

Up to 500 mm diameter and 600 mm in height with limited travel range.

Up to 420 mm diameter and 400 mm in height.