Krautkrämer WheelStar

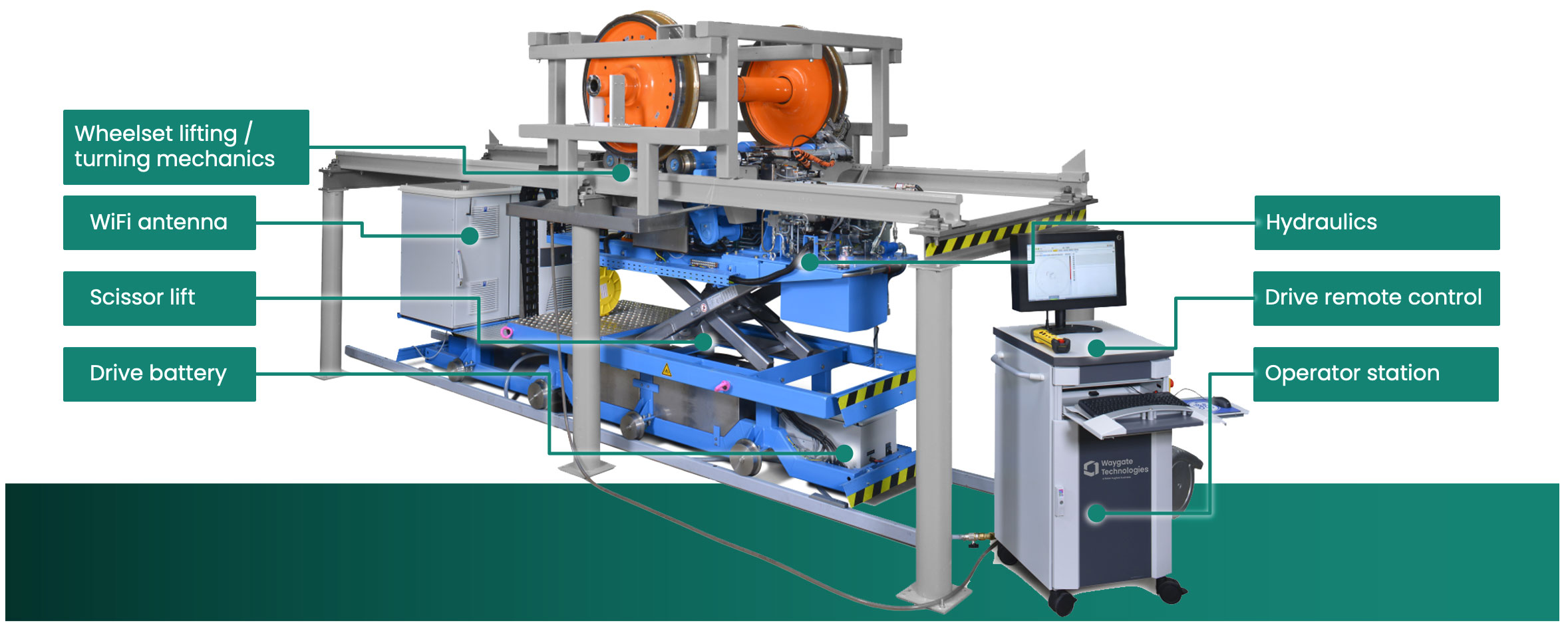

Krautkrämer WheelStar performs the complete inspection without removing the wheelset from the rail car, which provides maximum inspection throughput - the whole inspection cycle only takes 15 minutes per complete wheelset.

Train wheels are one of the most safety critical elements of rolling stock as they are exposed to high stress, particularly due to increasing speeds, loads and distances. Global railroad standards require these assets to be ultrasonically inspected on a regular basis. Rail operators, manufacturers and maintenance facilities are constantly seeking increased productivity and improved quality using non-destructive testing solutions. Krautkrämer WheelStar makes even overnight wheel inspection easy. It inspects the tread, face, flange and (straight) web areas of the wheel and visualizes the results in a projection view including automatic defect recognition (ADR) for easy interpretation by the operator.

Highlights

Benefits

- High return on investment

- Superior performance

- Reliable and easy automated process

- Trusted by customers, auditors and operators

Features

- USIP high-end electronics with modular architecture

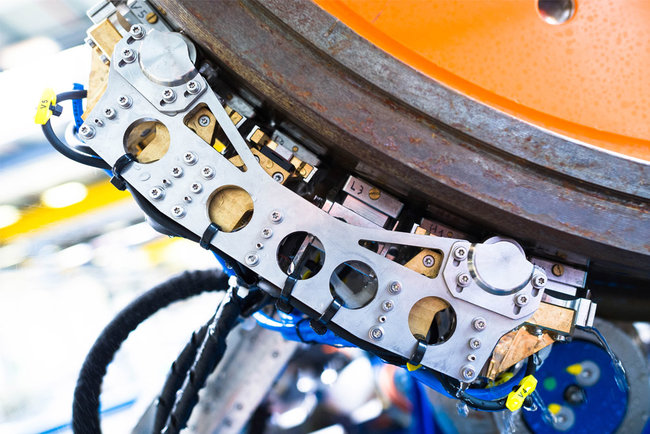

- 8 phased array probes, 6 conventional probes, 2 - 4 MHz

- Phased array: Radial and axial angle sweep

- Cable-free, battery powered, movable test mechanics, length ~ 4.5 m

- Wireless data transmission between test mechanics and operator workstation: Industrial Wi-Fi 802.11 g/n

- Workflow based software with integrated PLC control and stored wheel types

- Optional: Store ultrasound A-Scans for easy drill-down

Applications

- Inspected areas on rail wheels: Tread, face, flange, web (planar)

- Realized by set of conventional and phased array transducers

- 15 minutes cycle time per wheelset

- 90 seconds net testing time per wheel

- No wheelset removal required

- No time-consuming prepositioning

- Reduction of work preparation due to pre-programmed wheel types

- Fully automated inspection with highest reproducibility and traceability

- Less false calls due to elimination of geometric echos and automated defect recognition

- Intelligent highlighting of relevant incident increase inspection quality

- Short operator training

- Straightforward operating workflow with integrated PLC control

- Battery powered and cable-free operation

- Wireless data transfer

- Compliant to specific requirements of users around the world

- Automated reporting

- Long lifetime, highquality design

- Modular system with integrated high-end Krautkrämer USIP electronics

- Professional project execution, trusted by industry leaders

- Easy to operate, only short operator introduction required

- Guided workflow, from stored wheel type to automated data transfer and reporting

- PLC control fully integrated

- Easy result interpretation and fewer false calls thanks to automated defect recognition and geometry echo suppression

- USIP high-end electronics with modular architecture

- 8 phased array probes, 6 conventional probes, 2 - 4 MHz

- Phased array: Radial and axial angle sweep

- Cable-free, battery powered, movable test mechanics, length ~ 4.5 m

- Wireless data transmission between test mechanics and operator workstation: Industrial Wi-Fi 802.11 g/n

- Workflow based software with integrated PLC control and stored wheel types

- Optional: Store ultrasound A-Scans for easy drill-down

- 15 minutes per complete wheelset. 90 seconds net scan time per wheel

- Volumetric flaw: FBH >= 2 mm

- Surface flaw: Crack >= 5 mm length, >= 1 mm depth

- Inspected area: Tread, face, flange, web (planar). Realized by set of conventional and phased array transducers

- Complies: DIN 27201-7, other specifications on request