InspectionWorks Care

Unternehmen, die Maschinen und Verfahren zur zerstörungsfreien Prüfung (ZfP) einsetzen, um die Qualität und Zuverlässigkeit der von ihnen hergestellten und verwalteten Produkte zu gewährleisten, haben beträchtliche Investitionen in Geräte getätigt. Wenn die Geräte eingesetzt und verwendet werden, verschlechtern sie sich mit der Zeit und müssen gewartet werden.

Um solche Anlagen optimal zu nutzen, können ordnungsgemäße Arbeitsverfahren und Wartung die Leistung und Langlebigkeit verbessern. Um die ZfP-Anlagen optimal zu nutzen, kann die Datenwissenschaft Betreibern, Managern und Supportmitarbeitern helfen, den Status der Anlagen zu verstehen und entsprechend zu planen.

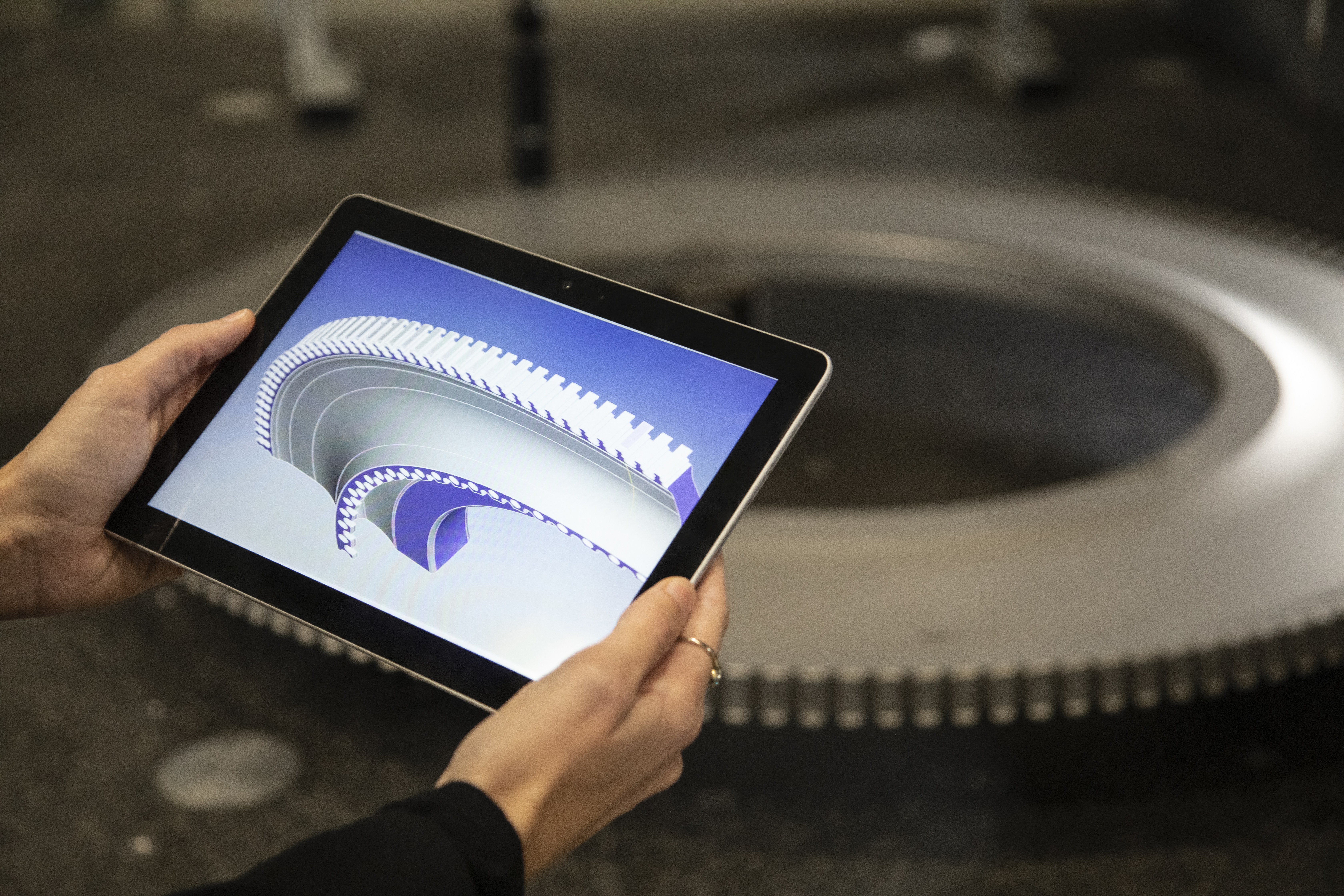

InspectionWorks Care ist eine anbieterunabhängige Überwachungslösung für Industrieanlagen, die Ihnen einen umfassenden Überblick über den Verschleiß und den Zustand der Komponenten von Radiographie-, Ultraschall-, Sichtprüfungs- und anderen Inspektionsgeräten im Außendienst und in Ihren Werken gewährt.Sie erstellt nahezu in Echtzeit Zusammenfassungen und detaillierte Darstellungen der Statusanzeigen von Maschinen und ihren Umgebungen. Die Software hat eine Vorwarnfunktion, die dem Bedienpersonal und anderen Mitarbeitern hilft, den zukünftigen Zustand einer Maschine vorherzusehen.

InspectionWorks Care hilft Ihnen, regelmäßig die Leistung Ihrer Maschinen und Geräte nachzuverfolgen, um Fehler und Probleme proaktiv zu erkennen und zu vermeiden.Dadurch profitieren Sie von längeren Betriebszeiten und weniger ungeplanten Ausfallzeiten, einer optimierten Wartungsplanung, mehr betrieblicher Effizienz, Qualität und Vorhersagbarkeit sowie geringeren Gesamtbetriebskosten für Ihre ZfP-Anlagen. InspectionWorks Care kann auf verschiedene Weise bereitgestellt werden und ist Teil verschiedener Support-Pakete.

Highlights

Benefits

Providing a comprehensive overview of the health status and condition of the components of factory and field systems

- Enable higher uptime and less unplanned downtime

- Drive operational efficiency, quality, and predictability

- Plan preventive maintenance and other activities with precision

- Improve system performance and lifetime

- Better anticipate on downtimes

- Proactively replace components

- Lower Cost of Ownership due to increased uptime

Features

InspectionWorks Care Dashboard and Performance Report work multimodally with a range of industrial asset management and smart factory KPIs

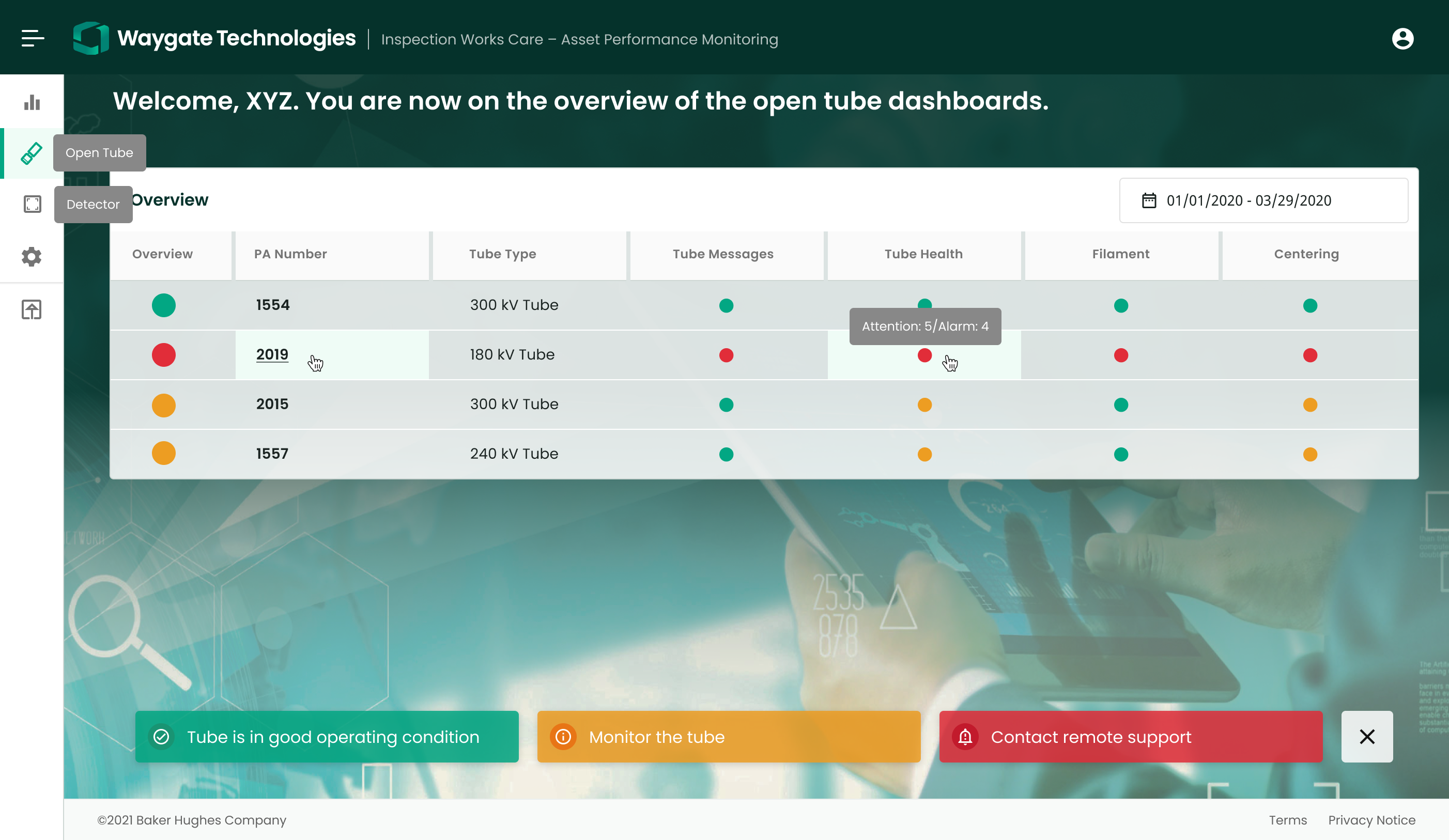

- InspectionWorks Care Dashboards is a high-level portal page that delivers insights into all the NDT systems in your fleet.

- InspectionWorks Care Performance Reports deliver all relevant information on the system’s condition including a comprehensive executive summary.

Applications

InspectionWorks Care helps track the health of the NDT fleet, effectively manage system maintenance and avoid unnecessary downtime.

- System messages: Monitors any occurrence of severe system message triggered by severe events.

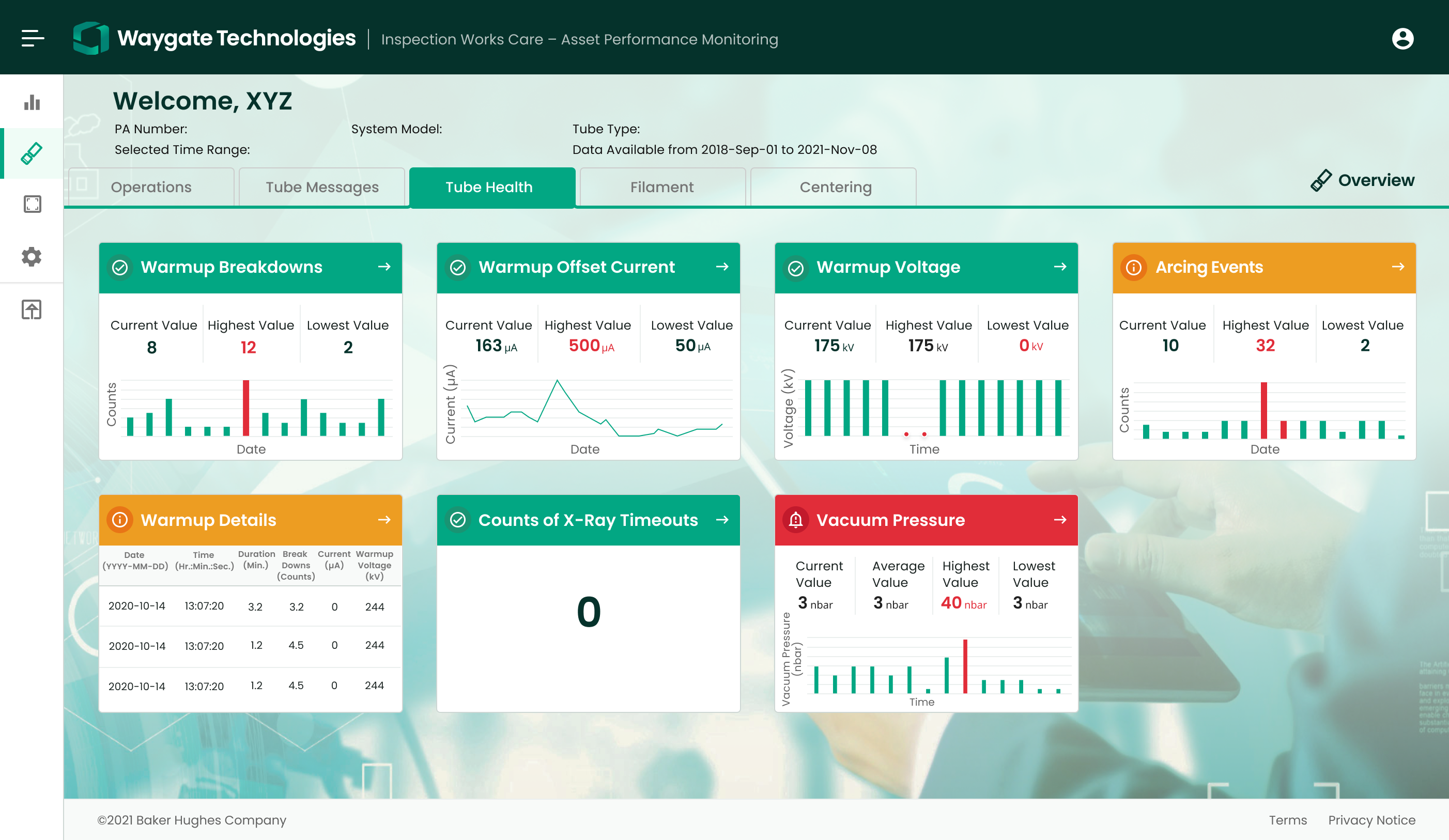

- Tube health: Monitors tube parameters such as warmup parameters, vacuum pressures, and X-ray timeout events.

- Filament: Monitors filament emission points values and filament failure date.

- Centering: Monitors the range of the X and Y centering values.

- Detector health: Monitors detector parameters such as SNR, CNR, CDF, etc.

InspectionWorks Care can be delivered as a cloud dashboard for anyone in the organization to consume. With the cloud-based Dashboard, users have access to high-level portal information on their X-ray or other industrial testing gear including detector and device health status. Users can also drill down to detailed KPIs. Trends can help determine optimal management of machines and other measurement. In the of Computed Tomography (CT), a hig- level portal page for all of your machine depicts tube, filament, centering, and detector business level indicators from green to red. Detailed detector info such as Signal, SNR,CNR, and bad pixels info as well as more specific tube data can also be found with the dashboards.

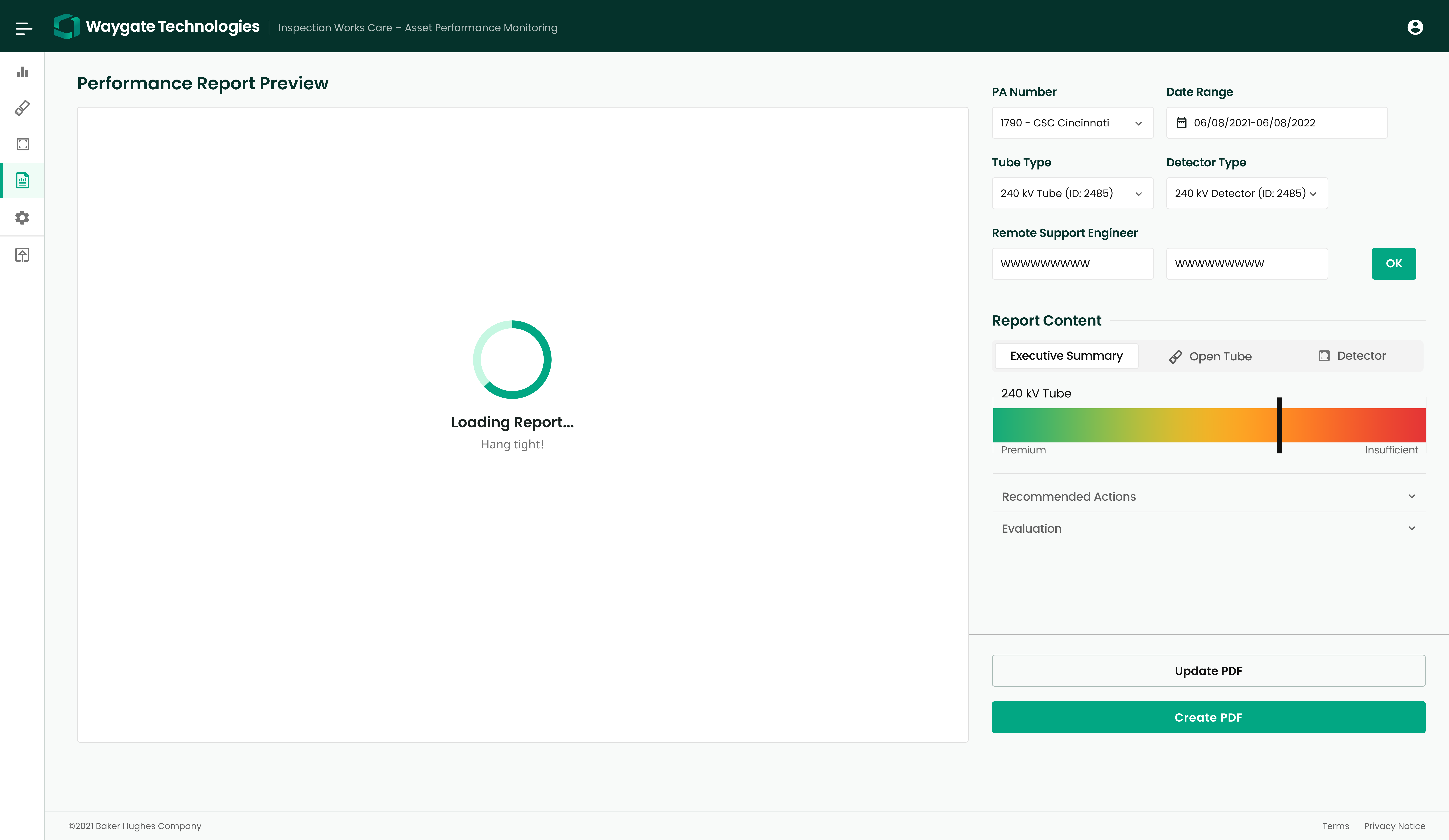

InspectionWorks Care can also be delivered as Performance Reports. The Performance Reports consists of a routinely sent multi-page performance reports covering executive and detailed information on the status of industrial machines and environments. These reports are also coupled with routine 30-minute touchpoint with a Waygate Technologies consulting expert who analyzes the current status and recent trends facing your factory machinery.

The monthly InspectionWorks Care Performance Report outlines the following categories: system messages, equipment performance statistics, maintenance procedural notes, and environmental status.

IW Care takes snap shots of data from industrial machines in near real-time or according to one’s preferences. Using Extract, Transfer, and Load (ETL) data science principles and techniques, the software turns disperse data into information easily consumed by operators and managers.

The software pulls from a growing list of KPIs which are constantly monitored. These include

- General Tube Conditions: Total x-Ray On Time, Total Tube Operating Time, Tube Operating Time, X-Ray On Time, System Message Events

- Warm-Up Events: Number of Breakdown Events, Warmup Offset Current, Warmup Voltage, Warmup Arc Events

- Operating Parameters: X-Ray Timeouts, Arching Events During Operation, Vacuum Pressure Over Time Plot, Centering X and Y values, Filament Emission Point, Filament Failure

- Detector Parameters: Detector KPIs including bad pixel count, bad pixel lines, bad relevant clusters, signal level, signal to noise ratio (SNR), offset level, electrical noise, MTF, CDF, contrast to noise ratio (CNR)

The software then parses this data, forming graphs with trending lines and reference points to help managers and engineers understand the healthier of their industrial assets. By using the solution, good asset planning is not only possible but greatly simplified.

InspectionWorks Care is a secure software solution that embraces technology from leading open source partners and third-party suppliers. The solution leverage security protocols and best practice workflows.

The software is multi-modal working with a range of industrial asset management and smart factory KPIs. It manages X-ray, Computed topology, ultrasonic, and other domains. It will be ready to hand smart factory features via wireless feeds. IT supports a variety of machine and factory systems including but not limited to X-ray open and closed tubes, DDA detectors, and servers and other infrastructure components. With InspectionWorks Care, uses can digest, analyses and transform manufacturing data into knowledge that can be acted upon. This action-oriented knowledge foster automation.

The IW Care Dashboard will provide a detailed overview of the health status and condition of various components of the CT system(s). For now this means open tube- and detector health monitoring.

The IW Care Performance Report is an asset management solution leveraged by IW Care software and consulting by Service Experts. This solution offers operational status and system health monitoring of the open tube and detector (at the moment). It includes (bi)monthly touchpoints with Service Experts to review the system(s) performance, analysis of the data and learn best operational practices.

These touchpoints are bi-monthly or monthly:

-

Monthly: if bought as a standalone option or when included in a Premium SSA.

-

Bi-monthly: in case when combined with a preventive maintenance contract, Essential SSA or Advanced SSA.

For now, the IW Care Dashboard and Performance Report is available for the v|tome|x series with open tube configuration and it evaluates the open tubes and detector’s health.

In the future, more data anaylsis will be available like closed tubes and generators.

In summary, IW Care outlines the following categories:

-

System Messages: Monitors any occurrence of severe system message events. Tube Health: Monitors tube parameters such as warmup parameters, vacuum pressures, and x-ray timeout events.

-

Filament: Monitors filament emission points values and filament failure date.

-

Centering: Monitors the range of the X and Y centering values.

-

Detector Health: monitors detector parameters such as SNR, CNR, CDF, etc.

The system requirements for InspectionWorks Care are minimal. All types of IXS Systems including those in V|tome|x series can be equipped with InspectionWorks Care if they are equipped with open tubes, common detectors (Dynamic 41 100, Dynamic 41 200 or DXR 250 RT) and meets the following requirements

-

Datos|x software version 2.10.1

-

Gain/Offset Tool

-

Image Quality Tools

-

Burn-In check

-

MTF

-

ASTM-bad pixel

-

Click & Measure Pack

-

-

Calibration Sphere (for MTF)

-

Log Agent

The above requirements are needed in order to gather data on the detector and derive the performance metrics as mentioned above. The OPCUA connector and the Gain & Offset tool is part of the InspectionWorks Care package.

The Image Quality Tools allow in-depth performance control to ensure high image quality based on ASTM standards. Each tool can be used separately based on the application requirement.

No, we offer an online version and an offline version.