Highlights

Benefits

- Ensures the proper amount of chemical dosing for your well based upon intelligent, real-time insights garnered from your ESP

- Makes precise, accurate decisions and automatically adjusts system parameters on-the-fly to boost well production

- Frees up personnel to prioritize sampling, treatment optimization, and non-ESP wells

- Removes the error, risk, and carbon emissions associated with manual intervention

- Overcomes the inaccuracies of traditional flow meters so you can confidently set your wells on auto-pilot

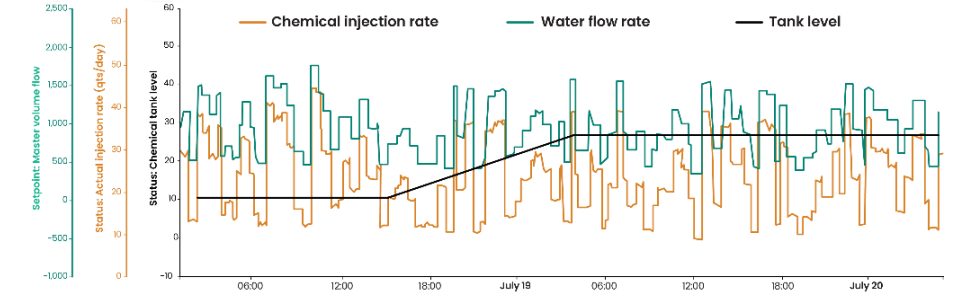

- Allows ESP and chemical trend plotting side-by-side for holistic performance analysis

- Reduces equipment and manpower intensity onsite, lowering well failure costs

Applications

- Unconventional oil and gas wells experiencing scale, corrosion, and/or sand control issues

Overview

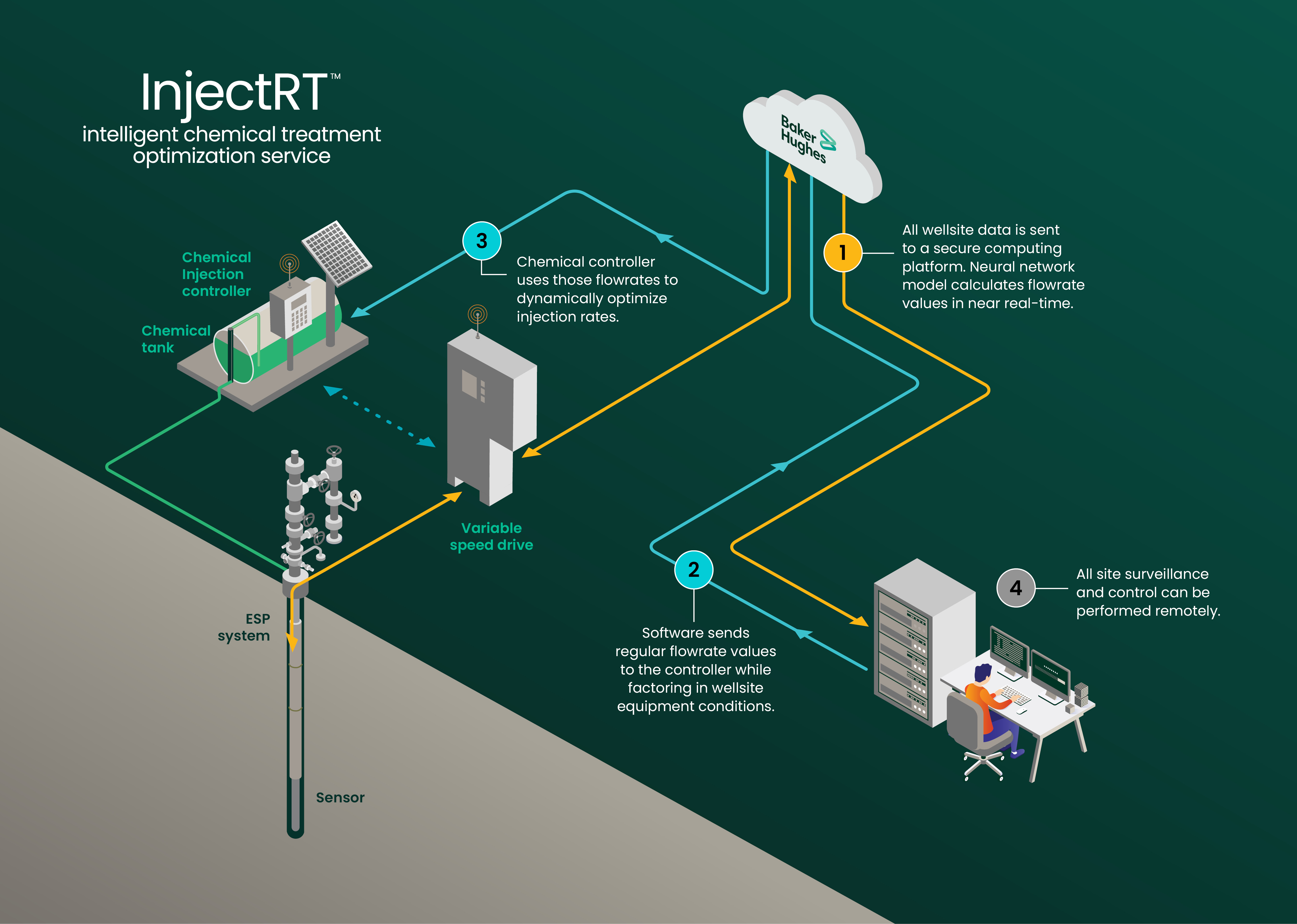

The InjectRT™ intelligent chemical treatment optimization service offers a highly precise, instantaneous injection system that ensures the proper amount of chemical dosing for your well based upon intelligent, real-time insights garnered from your ESP. InjectRT helps increase run life by mitigating risks associated with corrosion, scaling, and organic deposits.

More accurate

Inherent ebbs and flows create chemical dosing errors and emulsion issues. With a much higher level of precision and ccuracy than traditional flow meters, the InjectRT service eliminates manual dosing measurements and testing for less error.

Reliance on low accuracy flow meters to determine multiphase flow rate is replaced with a more accurate realtime virtual flow rate simulator. Physics-based models help analyze well profile, fluids, and reservoir productivity data to automatically and intelligently maximize operational efficiency. Built-in algorithms with years of learning ensure predictable performance, eliminating variances.

And, with InjectRT, all of your production data is located in one place eliminating the risk of ESP and chemical injection system incompatibility.

Autonomous

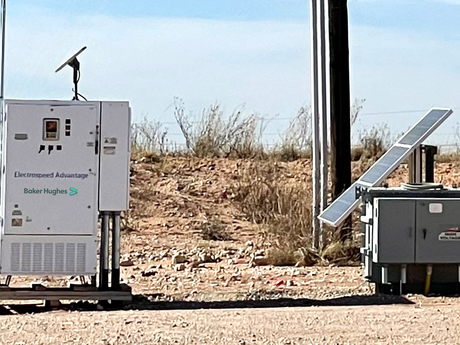

While variable speed drives can only speed up or slow down injection rates, the InjectRT service quickly analyzes data from your ESP to drive real-time adjustment of treatment rates through intelligent injection controllers installed at the wellsite.

A secure computing platform with years of physics-based modeling continuously collects and analyzes data to optimize and automate safe well site operations. These intelligent algorithms create highly consistent neuro pathways, so you can:

- Remotely adjust dosage rates eliminating over and under injection situations, saving chemical spend

- Deliver appropriate chemical dosage protecting asset integrity, lowering failure costs

- Alleviate ESP down time increasing production pump down time and chemical failures

- Schedule chemical inventory replenishment intelligently and efficiently to eliminate chemical runout and lower delivery costs

Efficient

The InjectRT service removes manual intervention for higher levels of efficiency and reduced HSE risk. With all of your data in one location, and with preconfigured analytics and machine learning capabilities, InjectRT makes precise decisions and automatically adjusts system parameters on-the-fly, so you can:

- Quickly analyze well optics and chemical usage trends

- Eliminate under or over-pumping, optimizing chemical spend

- Reduce run time, pump downtime, and subsequent workover costs and carbon emissions

- Reduce man hours spent on physical inventory checks on chemicals so you can spend time on more value-added work

- Optimize production

The InjectRT service instantaneously aligns chemical injection rates with ESP-derived virtual flow rates.