Highlights

Highlights

Benefits

- Precisely tailored to operator requirements; patented technology improves efficiency, size, reliability, weight, and cost

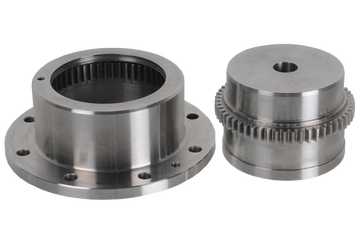

- High-accuracy gears with non-contact bearings designed for over 100,000 hours of continuous operation

- Load-sharing epicyclic systems split torque to several paths, reducing load on individual gear elements thereby reducing size

Features

- Purpose-built to exacting customer specifications and ISO/AGMA/API standards

- Proven outstanding reliability with highest efficiency

- Gearbox diameter and skid width minimized while guaranteeing drivetrain integrity

Capabilities

- Configured in three principle arrangements to allow different ratio, torque transmission, and shaft rotation characteristics

- Power between 0.5 MW and 37 MW, transmitted torques up to 4.35 mNm, and operating at speeds from as low as 20 rpm to 40,000 rpm

Overview

Overview

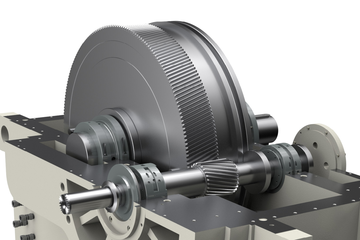

Our Allen gears epicyclics can be used between a wide range of prime movers and driven equipment. Used on almost all gas turbine driven sets worldwide, our units are world leaders in the 3-20 MW range. Many of the major engine manufacturers and packagers around the world use our gears for gas and steam turbine generator drives.

Many years have been invested in perfecting our manufacturing technology that's critical for successful operation of high-integrity transmissions, and to meet the ever-increasing demands of high speed and high-power applications.

In-house design and manufacture of all the critical components (e.g. gears, bearings, carriers, and couplings) gives us complete control over quality, and the ability to ensure highly reliable transmission.

All our units are custom-designed to suit the exact technical requirements of the application. Whether the customer's primary concern is efficiency, weight, or anything else, we'll deliver the perfect solution.

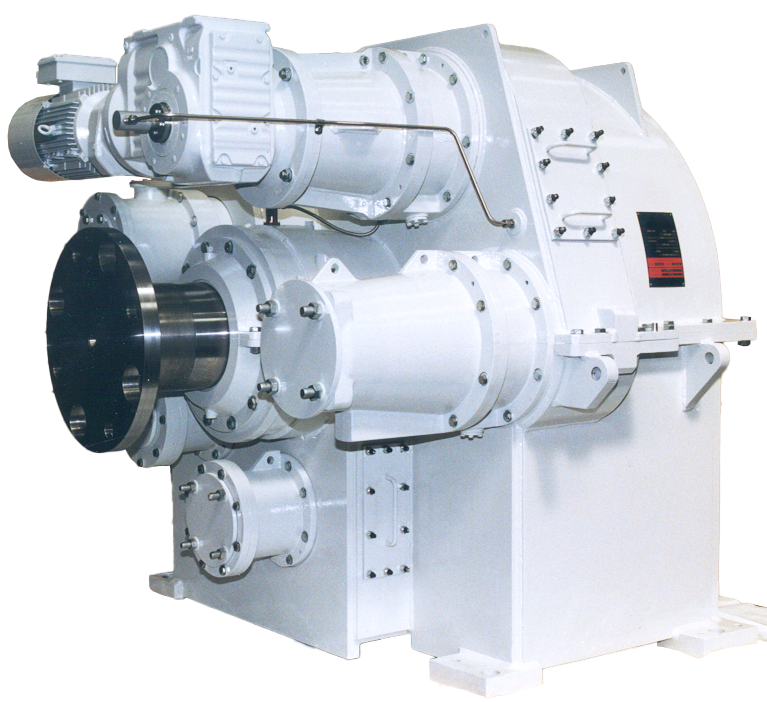

Gas and steam turbine gearboxes—power generation

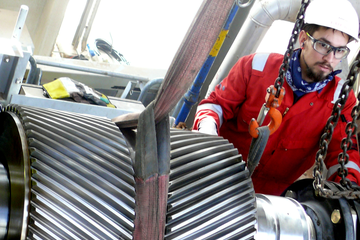

Our units are installed in critical operations around the world including, oil rigs, chemical plants, hospitals, and localized power stations. Design features include:

- Generator-mounted gearboxes

- Turbine-mounted gearboxes

- Lubrication pump, fuel pump, etc., power take-off (PTO) drives

- Starter-drive, power take-ins (PTIs)

- Integrated barring drive gear

- Instrumentation packages for condition monitoring

- Integrated lubrication systems

Vertical epicyclic gearboxes—cooling-water pumps

Our vertical epicyclic geared pump drive enables substantially smaller electric motors than traditional direct-coupled motor drives. This size reduction contributes significantly to an overall cost savings in both installation and operation of a typical circulating pump package.

- Gear units designed to suit motor and pump interfaces

- Gearcase can be designed to support weight of drive motor

- Reduced overall package size

- Coaxial drive train (motor, gearbox, pump)

- 99% mechanical efficiency

- Self-contained full-duty lubrication system

- Reduced noise and vibration

- Transfers thrust or accepts external thrust via integral thrust bearing

- Eliminates the need for a low-speed coupling

Hydro turbine gearboxes—power generation

As a leading supplier to the power-generation industry, we have unique experience in applying this technology to hydro-turbine projects. A geared system offers the ability to drive a lower-cost, high-speed generator with a low-speed turbine. Low-head turbines running at 40–200 rpm with a power output of 1–30 MW can be geared to high-speed generators, resulting in higher overall efficiency.

Allen Gears epicyclic technology constantly outperforms other gear systems for efficiency and reliability. Our patented technology, combined with industry-leading manufacture and design quality, provides the very best compact solution for small to medium hydro turbine systems.

- High efficiency of typically 99% translates directly into additional revenue

- Co-axial arrangement reduces overall size

- Compact, smaller, and lighter than alternatives; reduces overall system size

- Lower pitch-line velocity produces less noise

- Horizontal and vertical arrangements

- Multiple stage solutions for high-ratio speed increasers