Highlights

Highlights

Benefits

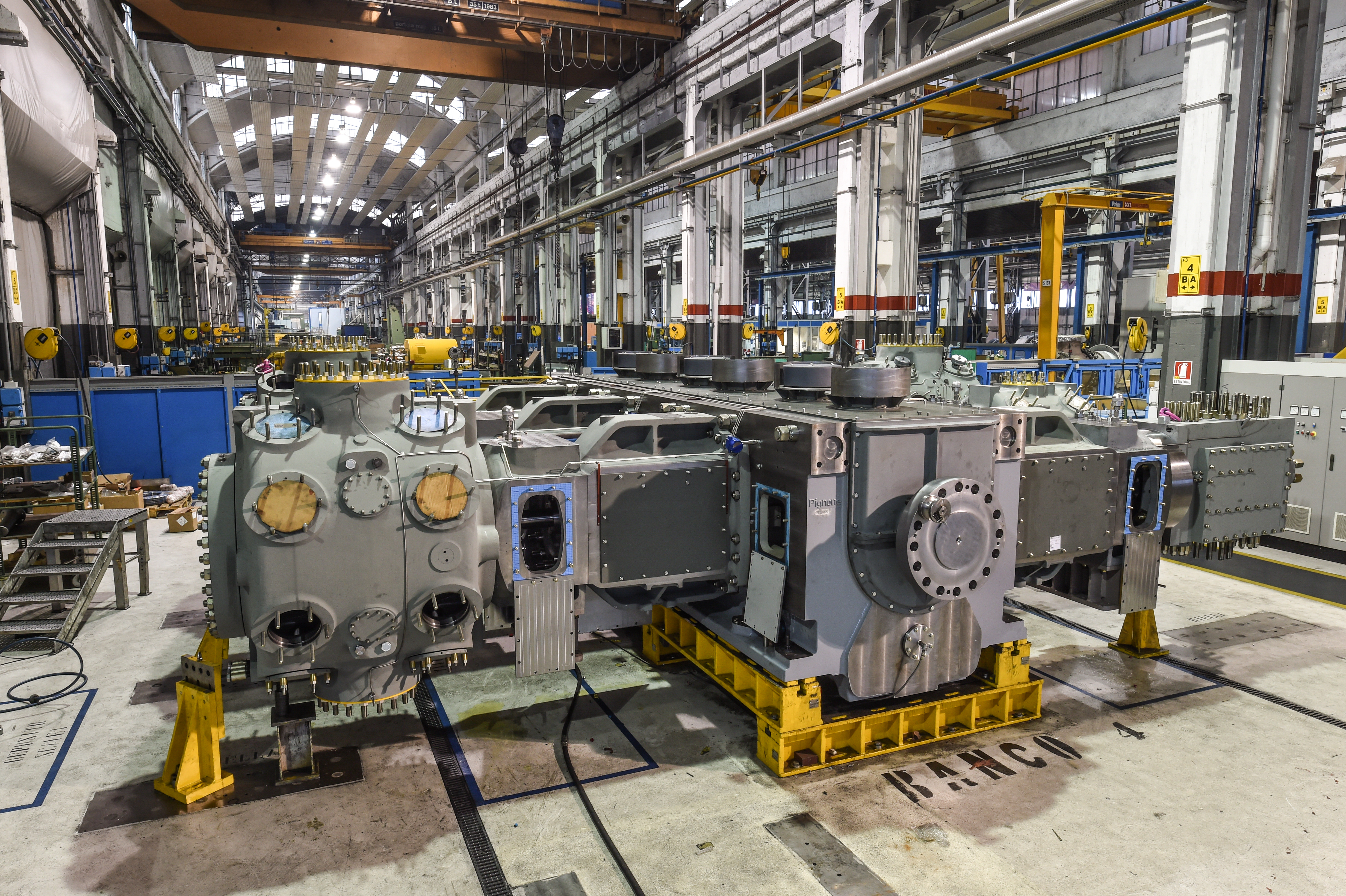

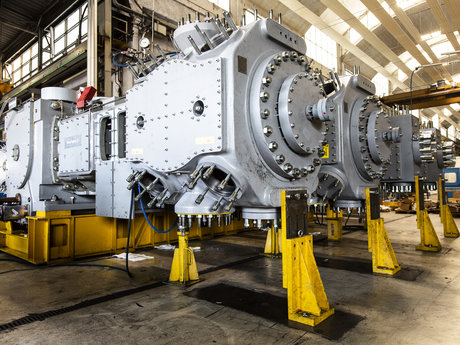

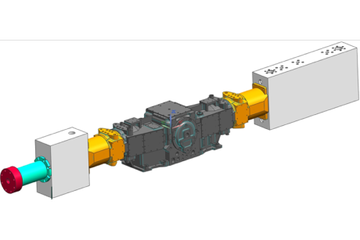

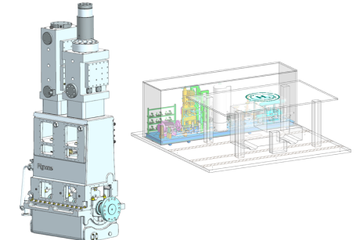

- Fully integrated solution including motor, vessels, piping, supports, and control panel

- We have unique in-house ability to perform plant-wide acoustic and dynamic piping analyses

- We offer 10 models with designs and materials optimized to improve uptime for each application

Features

- Modular design allows up to 10 cylinders per frame, with cylinder size up to 1,250 mm

- Machines can range from 100 to 20,000 kW, and up to 800 bar

- Double-acting piston with 1,980 kN load capability; a fully balanced crank mechanism is available for offshore applications

Applications

- All refinery processes

- Natural gas

- All hydrogen services

Overview

Our API 618 compressors are well-known for decades for low pulsation and vibration, which translates directly to exceptional efficiency, low maintenance, and low power consumption. They are used across a wide range of refinery, petrochemical, and natural gas applications including hydrocracking, ammonia, refrigeration, re-injection, and gas lift.

*At max. speed and max. number of cylinders

One century of hydrogen experience

Our technologies and solutions for API 618 process compressors are known in the refinery and petrochemical industry for unparalleled reliability and efficiency. With more than 800 units installed for refinery hydrogen applications, our API 618 compressors can manage hydrogen compression up to 170 bar with compression ratio high enough to match any requirements. Optimized for sliding pressure and capacity operations, our technology can also guarantee best-in-field efficiency for storage applications.