Highlights

Highlights

Benefits

- High pressure and temperature capabilities: 670 bar, 450°C

- High efficiency and reliability with simplified maintenance

- Pull-through design available on request

Features

- Internal volute casing and a back-to-back impeller configuration

- Low net positive suction head

- Reverse hydraulics available to operate as hydraulic power-recovery turbine

Applications

- Refinery and petrochemical: reactor feed in hydrocracking, ammonia charge processes, carbamate

- Enhanced oil recovery injection: treated seawater, seawater, CO₂ injection, oil flow line

- Gas treatment: amine services for gas sweetening

Featured Video

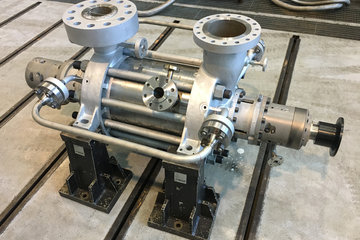

Our DDHF multi-stage, double-casing, centrifugal barrel pumps are engineered for reliable 20-year operation, well proven with over 1,000 units installed worldwide. They’re highly efficient with an optimized hydraulic design that provides low net positive suction head (NPSH)—close to the maximum theoretical threshold.

Specification

Proven performance, upstream and downstream

DDHF pumps incorporate proven solutions to common materials, pressure, flow rate, installation, and integration challenges faced in upstream oil and gas applications. They also deliver exceptional performance in heavy-duty refinery and petrochemical applications—easily handling fluids with low specific gravity, pressures reaching 670 bar, and temperatures up to 450°C.

Key design features include an internal volute casing and a back-to-back impeller configuration, which simplifies maintenance, reduces downtime, and guarantees high reliability. The package also includes customization options to best suit each customer’s unique project requirements.

CO2 applications

To reduce carbon footprint, our DDHF product line includes a compact machinery layout option for high-density CO2 pumping. An extensive research campaign was performed with International Labs to characterize many CO2/hydrocarbon mixtures, and design the hydraulics to best fit the fluid evolution. The pump's performance has been extensively validated with rigorous multi-speed testing at our factory.

Full lifecycle support

We can provide full onsite support during installation and commissioning to guarantee flawless execution and quick response.

After installation, we can support continuous improvement throughout the pump’s operating life with conversion, modifications and upgrades, including:

- Impeller modification or diffuser replacement to match actual operating conditions

- Wear-ring upgrade to composite materials that reduce internal leakage, and increase efficiency with clean fluids

- Super finishing of internal wetted surfaces to increase efficiency

A remote monitoring and diagnostic service is also available.