Highlights

Highlights

Benefits

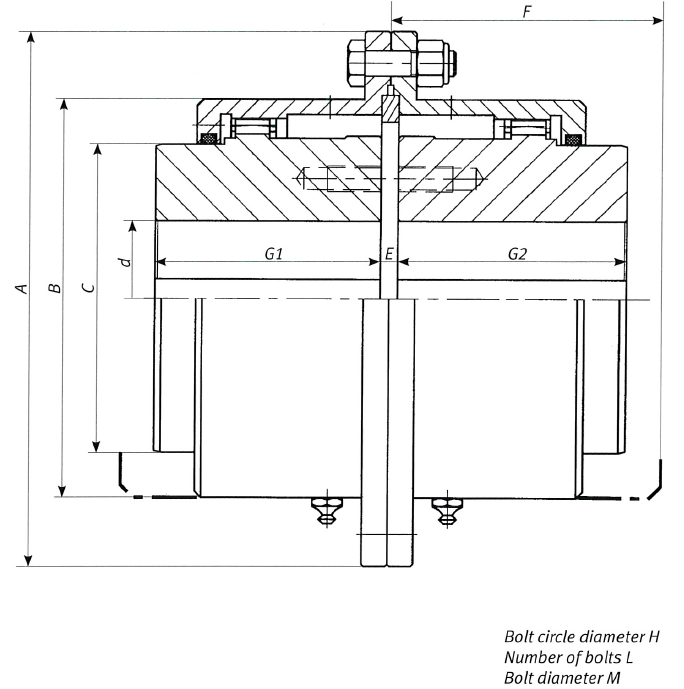

- Compact series (AFC) can be mounted on shafts up to 265 mm diameter for optimized overall dimensions in all industries

- Heavy-industry series (AFX) fits shafts of up to 900 mm diameter; high torque capacity for extreme loads

- Custom design capabilities to meet any requirements

Features

- Construction dedicated to iron and steel norms and derived from AFX and AFC standards to match challenging power transmission requirements

- Can be balanced per ISO/AGMA/API requirements

- ATEX certified for nuclear and explosive areas

Applications

- Transmittable torques Tt calculated for 12 hours per day operation

- Misalignment: from 0°30’ (no-load) to 1°30’ (load)

- Service factor Ks: 1 and speed factor Kv: 1

Overview

Overview

Since 1946, we have delivered thousands of COMELOR and Lufkin Gears couplings. This webpage reviews our two standard series (AFC and AFX), which have decades of proven service in all kinds of transmission applications worldwide. We have the experience, knowledge, and specialized engineering expertise to develop a customized solution that meets any requirements for your industry.

The basic speed for AFC and AFX30 to AFX180 couplings is 1,000 rpm. For AFX200 to AFX650 couplings, the basic speed is 300 rpm. Coupling capability can be adjusted based on customer application speed.

Lubrication

Our couplings are greased as a base configuration. In the case of specific applications involving higher rotation speeds or specific customer requests, we can propose different lubrication solutions, including:

- Oil filling

- Oil sprayed though nozzles as close as possible to the teeth and collected in a coupling guard

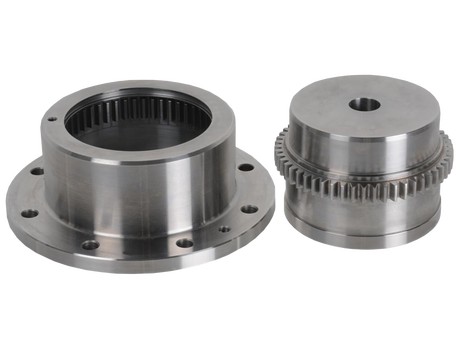

AFC Series

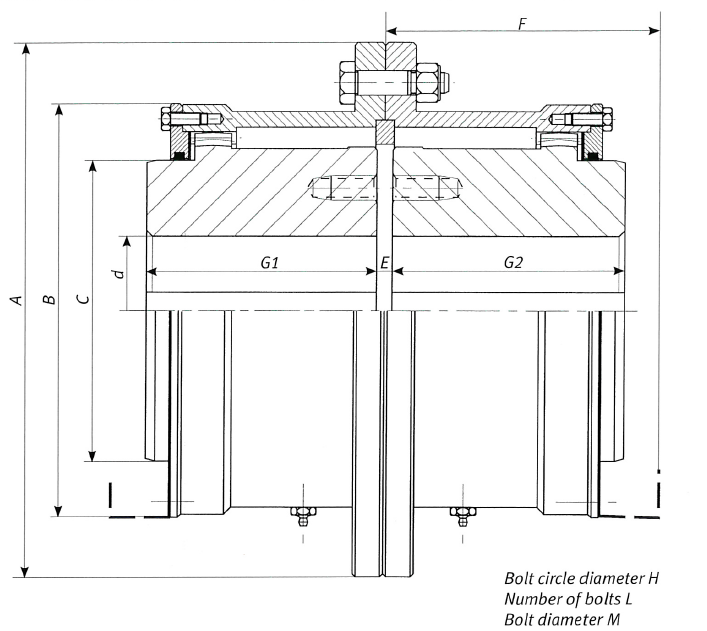

This series is designed for applications in every industry, with simple construction and all the essential qualities that characterize flexible gear couplings. Construction includes a centering ring that enables complete interchangeability of the flexible gear coupling halves. Its dynamic characteristics (moment of inertia, weight, and balancing possibility) make it ideal for high-speed applications such as connection between speed increaser/reducer gearbox and compressor or turbine.

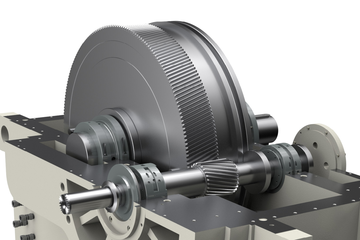

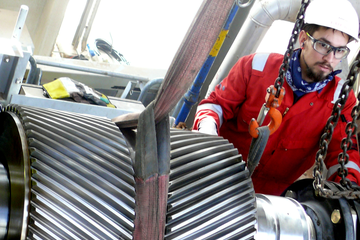

AFX Series

With a high torque capacity for applications requiring extreme loads, this series is designed primarily for heavy industry such as steel, aluminum, copper, rubber, sugar. It differs from the AFC series by its removable sleeve covers. The AFX series enables connection to shafts of up to 900 mm diameter, and the weight of such large couplings can exceed 10 tons.

See the resources section below for downloadable PDF specifications tables for the AFC and AFX series.

Custom designs

Our custom coupling designs are derived from the AFX and AFC standards. They present specific capabilities developed to match the most challenging conditions and precise power transmission requirements while mitigating angular misalignment.

- Disc brake coupling: fitted with a disk brake; used, for example, in hoist drive of overhead crane

- Brakewheel coupling: fitted with a handwheel brake; used, for example, in hoist drive of overhead crane

- AFR rope drum carrier coupling: used, for example, as connection between speed reducer and winch drum

- AGD coupling with large misalignment capacity: provides an increased capability to deal with misalignment; used, for example, in mill roll drive

- Disengageable coupling: can be engaged or disengaged with the driver and the driven equipment; used, for example, as connection between tandem motors

- Shear pin coupling: fitted with shear pins used as over-torque protection; used in any application where over toque can occur, for example, crusher or roll mill

- Telescopic coupling: fitted with a sliding capacity of the hub, enabling it to accommodate variable distance between shafts; used, for example, for hydrafiber drive in a paper mill

- AGV high speed coupling: designed for high-speed applications, for example, as connection between speed increaser/reducer gearbox and compressor or turbine