Highlights

Benefits

- High reliability and low vibration levels

- Highly efficient for condenser cooling

- Light and compact design simplifies installation and improves ease of maintenance

Features

- Modular design provides flexibility for tailored solutions

- Duplex material for sea water applications

- Standards: ISO, HIS, (design); EN, ASTM (materials); ISO (performance)

Applications

- Water transfer, irrigation, desalination, waste water

- Combined-cycle power plants

- Oil and gas, LNG (sea water and fire-fighting systems), chemicals

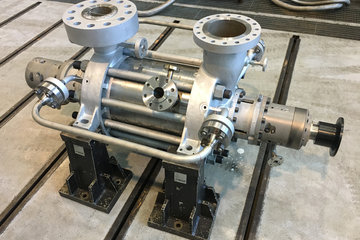

The Saturne™ pump, licensed by GE Steam Power, is a vertical turbine pump (or suspended bowl pump) for use in a wet pit with a vertical water column. It's driven by a direct motor, or through a gearbox, installed on the pump head or a separate floor. It's designed for large flows up to 20 m3/s, which is beneficial for massive irrigation purposes or water intake in large desalination plants. There are over 500 Saturne™ pumps currently operating around the world, and they are well known for high reliability and low vibration—less than 1.8 mm/s.

The pump consists of a high-efficiency hydraulic module with axial, mixed flow, or centrifugal impellers; shaft line immersed in the pumping fluids or with an independent flushing system; and fabricated casing, which includes the discharge column and elbow.

The portfolio includes various types

- Welded or casting components

- Carbon steel, stainless steel, duplex or super-duplex

- Pull-out or non-pull-out

- Several technologies for guide bearings: rubber, graphite, ceramic

Materials for seawater applications

- Impeller: duplex or super duplex stainless steel

- Pump casing: duplex or super duplex stainless steel

- Column and delivery head: duplex stainless steel

- Shaft: duplex stainless steel

Materials for raw and fresh water

- Impeller: stainless steel

- Pump casing: cast iron or carbon steel

- Column and delivery head: carbon steel

- Shaft: stainless steel or martinsitic steel

Specifications