Highlights

Highlights

Benefits

- 100+ years of engineering expertise, innovation, field-support experience, and customized solutions worldwide

- High-stiffness and ultra-compact solutions with reduced weight, and ultra-low noise and vibration characteristics

- Customization options enabling high degree of flexibility for integration with complex shaft-line configurations

Features

- Integral or shrunk-on collars can withstand very high sliding velocities while supporting gas processes external forces

- Pinion(s) shaft provided with Hirth teeth, integrated shaft-driven pump to feed the system in oil for any operating conditions

- Design and performance validated by rotor-dynamics (impellers cross-coupling), FEA (casing modal) and specific running tests

Applications

- Air and other gas compression with electric motor or turbine driver, for energy recovery with turbo-expanders driving generators

- Pinion speeds up to 50,000 rpm; power transmission up to 25 MW; gear ratio up to 15:1

- Various chemical and oil and gas applications including gas compression, air separation, power generation and carbon capture

Overview

Overview

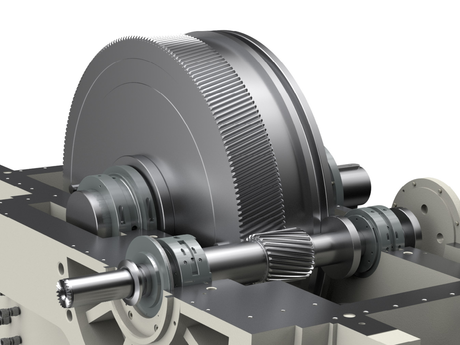

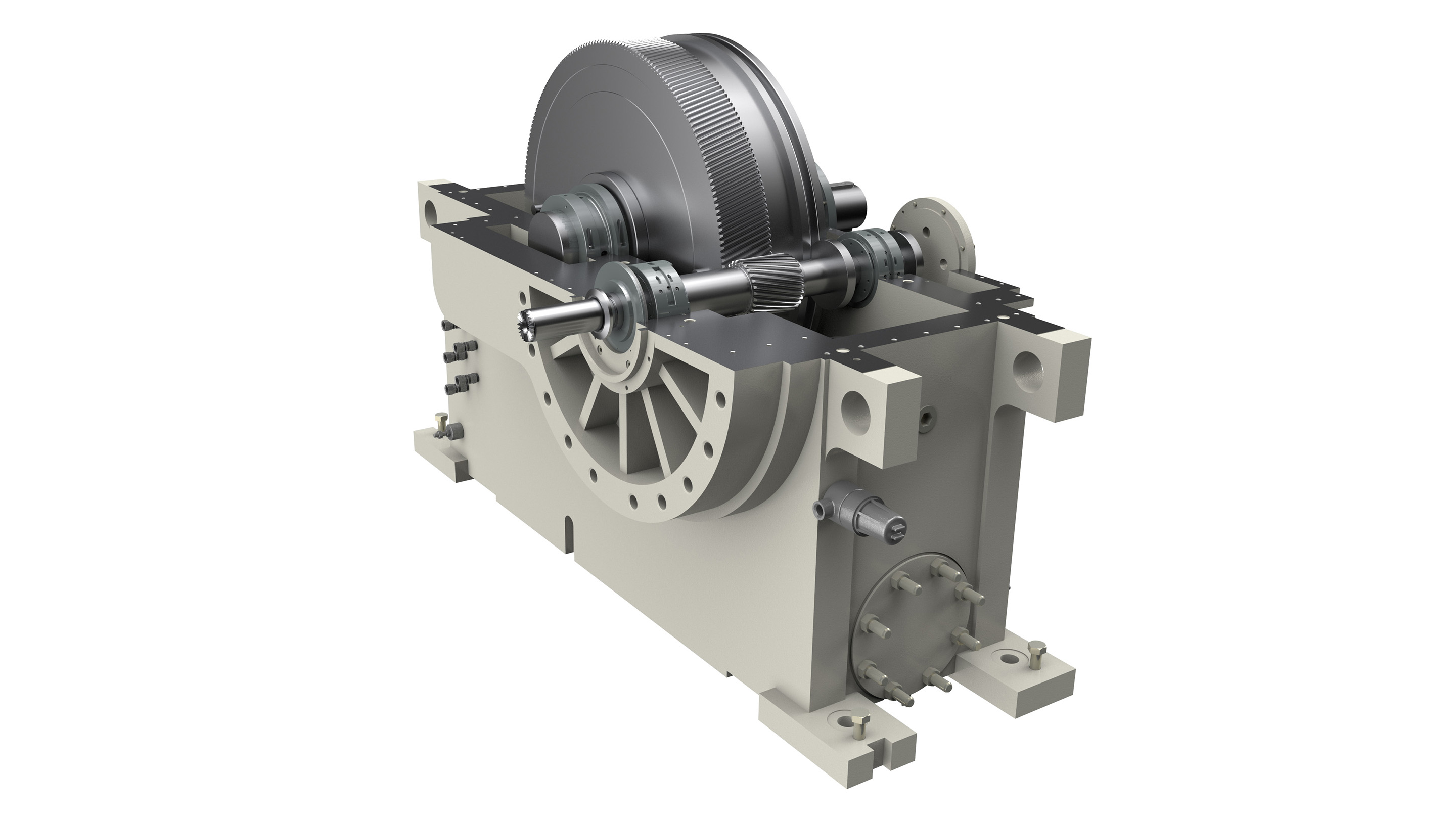

Stout, sturdy, and stable

Lufkin Gears integral gearboxes are custom-designed to meet growing industry needs and requirements. Each customer gets our full engineering support to ensure that all collaboration needs are met so that even the most complex design is carried out smoothly, and the best possible product is delivered. These units are robust enough to handle the loading of heavy impeller housings, yet maintain the finesse needed to avoid vibration issues. They can be designed to meet API613 through API 617 and ATEX if required.

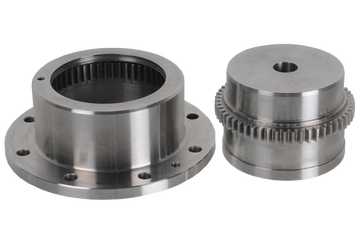

Gear teeth and thrust collar

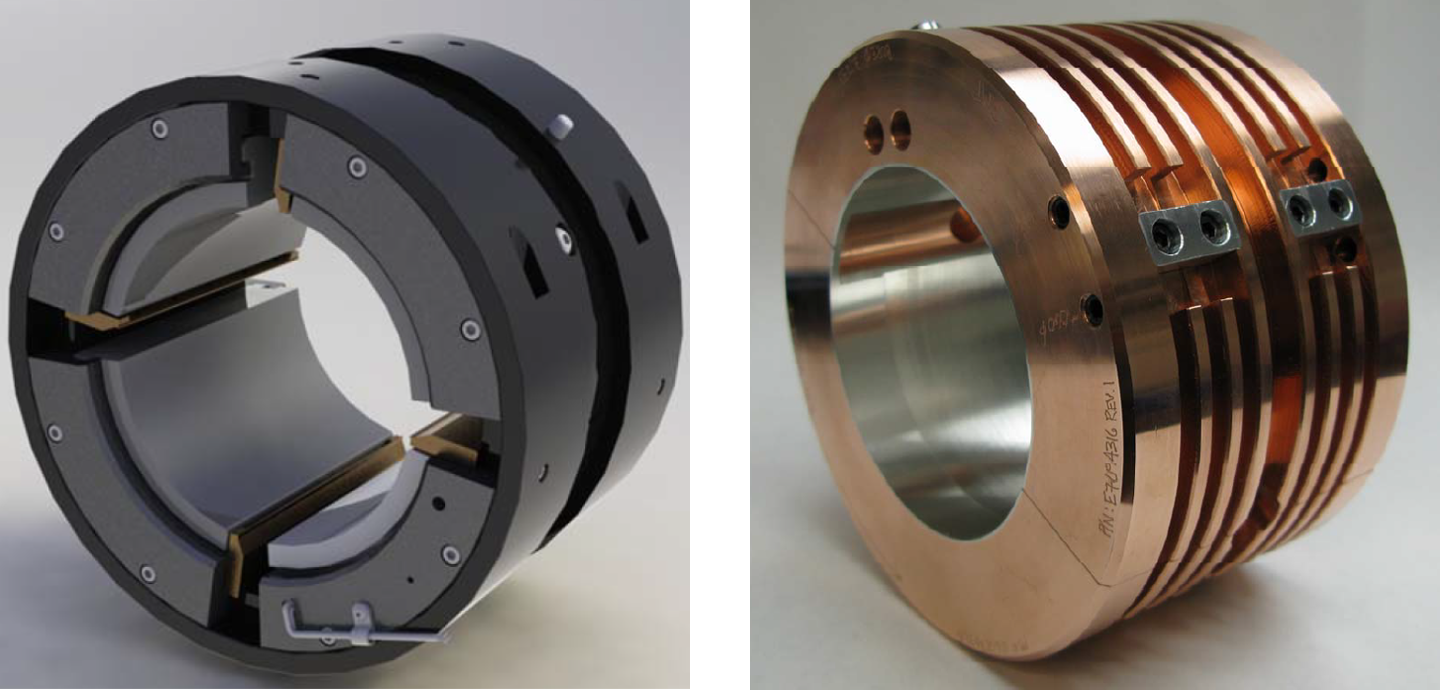

Gear teeth are typically preferred to be single-helical for better axial end play control, but can be double-helical when suitable. For single helical teeth, we will utilize either integral or shrunk-on thrust collar(s) to eliminate the need for a redundant thrust bearing on the high-speed pinions—greatly improving unit efficiency. Teeth are precision ground and can be modified to correct torsional and bending contact mismatches. Gear teeth and thrust collar(s) can be case-hardened, nitrided, or through-hardened as needed.

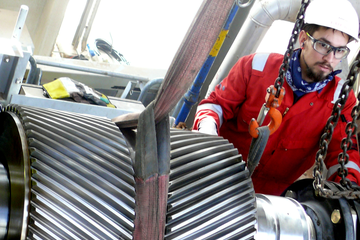

Gear casing

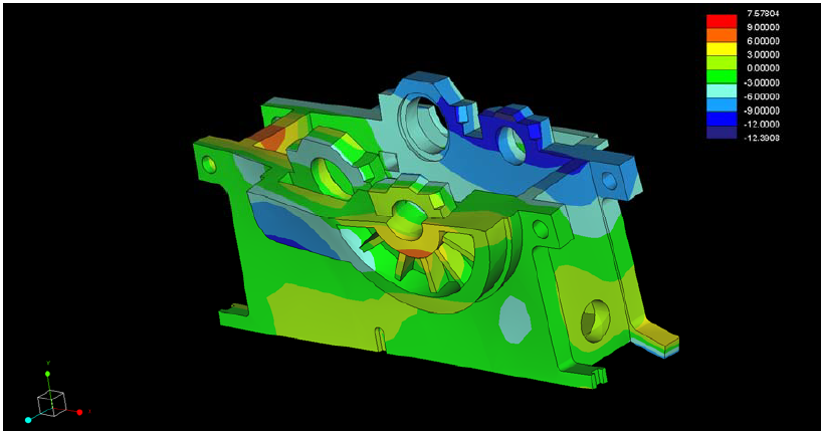

Each gear casing is custom-designed to meet turbo equipment mounting and loading requirements which include a dedicated finite element analysis (FEA) to optimize the architecture. The casing cover can be designed to be dismantled without removing the impeller casing. Bearings can be internally constrained to secure the gear elements in place if the cover is removed. The gear casing is fabricated out of heavy steel plate for robustness and stiffness to ensure long life and stability. Oil-pump mounting solutions are available as shaft-driven or offset-mounted on the casing if needed.

Bearings

Multiple bearing design options are available to suit the application. Multiple styles of sleeve bearings, taper-land thrust, tilt-pad journal, tilt-pad thrust, and integral squeeze-film damper bearings can be used to meet a variety of design considerations.

Stability

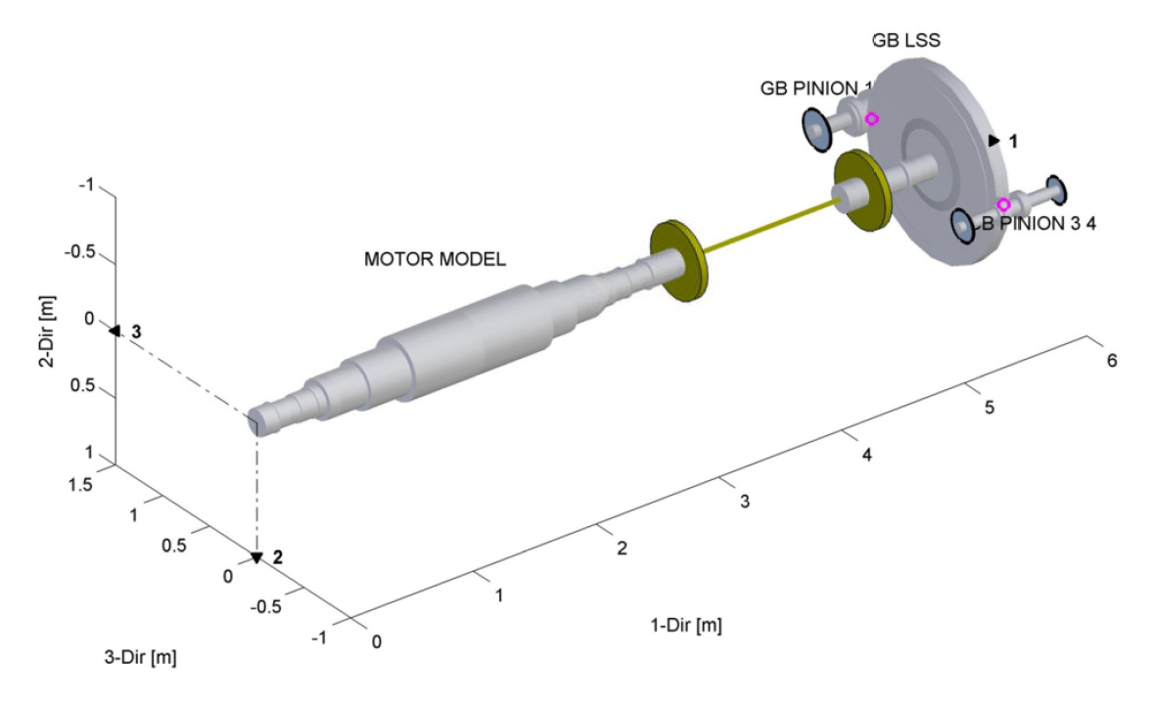

Our integral gear units are designed with stability in mind. We custom-tune each pinion to operate safely away from critical speeds, working with the customer to establish impeller and seal weight/inertia requirements and impellers cross-coupling data to ensure trouble-free operation. We can provide undamped, damped, and stability analyses as required by API 613 and 617.

Condition monitoring

Bently Nevada or similar equipment is available on all shafts to monitor radial and axial vibration as well as phase angle. Magnetic speed pickups can also be mounted to sense the gear teeth, or mounted to sense a gear with a specific tooth count. We use embedded simplex and duplex RTDs or thermocouples for bearing temperature monitoring.