Highlights

Highlights

Benefits

- High power levels while performing both at extremely high and cryo operating temperatures and achieving great pressure ratio

- Can handle all pure or mixed natural gas, and petrochemical products with liquid up to 35% of weight at discharge

- We can do standard testing to ASME PTC10, Type 2 with option for full-load string test with up- or downstream compressors

Features

- Aerodynamics and multistage arrangement based on specific process needs to provide high pressure ratios or high flow rates

- Hydraulic, pneumatic or electric actuator control patented multilink IGV to guarantee precise control up to 130% design flow

- Totally sealed train, single-shaft with high speed generator on magnetic bearing available for low power application (<1 MW)

Applications

- Cryogenic gas treatment and dew point control applications

- Petrochemical (syngas, H₂ rich process)

- Waste-to-value applications (LAES, pressure let-down, geothermal, waste-heat recovery)

Overview

Overview

Our turboexpander-generator designs respond to specific industry needs for increased capacity, reduced costs, and maximized reliability in a wide range of fullstream and low carbon applications. Our fleet ranges from 0.3 to 20 MW with a proven record of performing at extreme temperature and pressure conditions, delivering the highest power level.

Shaft power

0.3 to 20 MW

Max. speed

40,000 rpm

Inlet and outlet flange

4 to 64 inches

Max. inlet pressure

150 bar

Temperature range

-270°C to +315 °C (or +500ºC without adjustable nozzles)

Max. enthalpy drop per stage

300 kJ/kg

Max. liquid content at suction

1% weight

Max. liquid content at discharge

35% weight

Energy recovery from heat injection and pressure

In 2019, we delivered a new concept for turboexpander generator designed to convert the natural gas pressure energy into electricity as the main component of our Heat Injection Pressure Energy Recovery (HIPER) system—an optimized natural gas waste-pressure recovery system for pressure reduction stations.

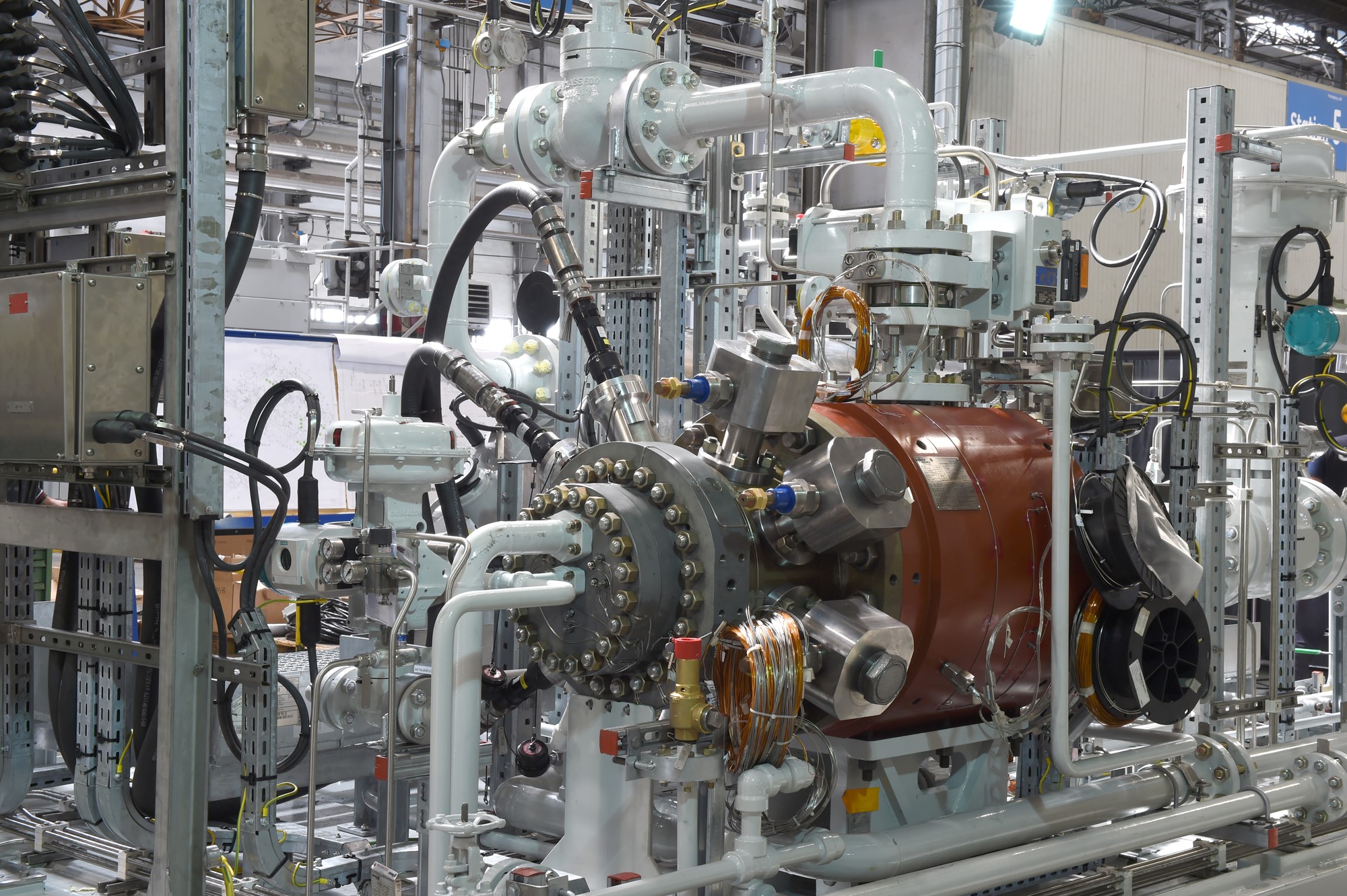

Rated for 85 barA pressure, this 300 kW expander is a single-shaft machine directly coupled with a high-speed generator at 30,000 rpm to avoid gearbox and related auxiliaries. This configuration is completely oil free, as it is supported only on magnetic bearings in a totally sealed case, which avoids gas leakage, flares, and vents to atmosphere.

Advantages suggest its adoption in pressure let-down applications either as a single machine or a whole system, as long as process data are compatible.

We have manufactured three large 17 MW double-stage expander generators. Two are operating in Canada and Brunei at waste-heat recovery plants based on our organic rankine cycle (ORC) to recover gas turbine exhaust heat.

The design is based on two integrally geared stages, the largest having a 1,000 mm diameter impeller, and a multi-link inlet guide vane system suitable for high process gas temperature, up to 315°C design temperature.

Regardless the required installation, the design can guarantee the same high performance in either a cold or tropical environment.