Highlights

Highlights

Benefits

- Low overall cost of ownership with exceptional reliability and long life

- Extended maintenance intervals

- Drawing on 90 years of engineering expertise, innovation, and support

Features

- Purpose-built to exacting customer specifications and ISO/AGMA/API standards

- Robust designs with rigid case construction

- Low noise, low vibration, and industry-leading material specifications

Capabilities

- Speeds up to 70,000 RPM and power up to 100 MW

- Cast and fabricated casings

- Integrated lubrication, vibration, and temperature monitoring

Overview

Overview

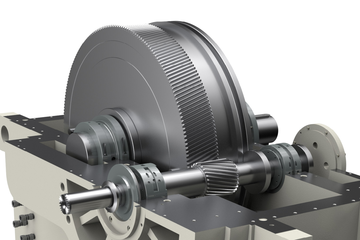

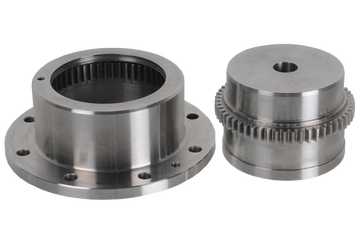

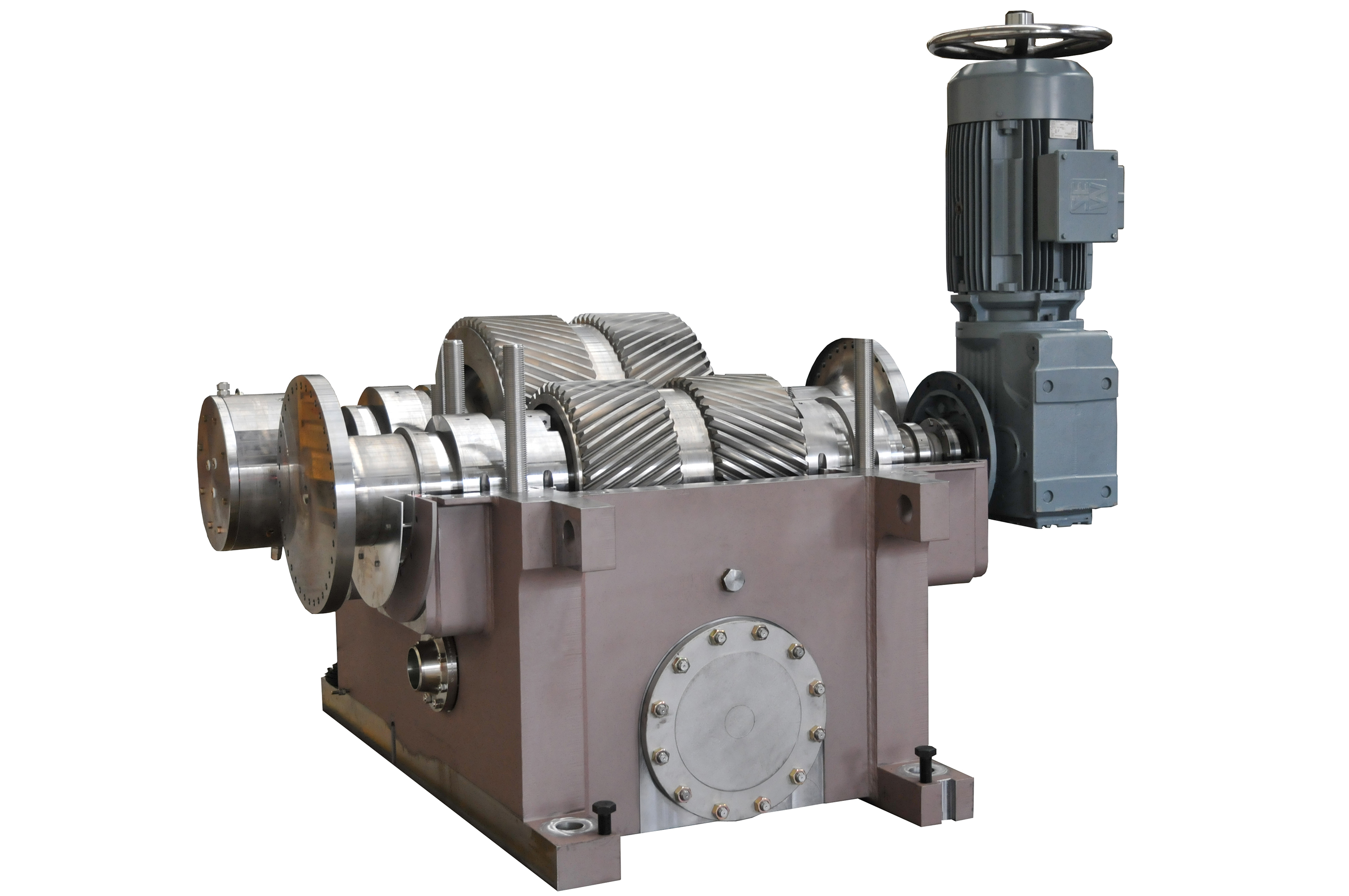

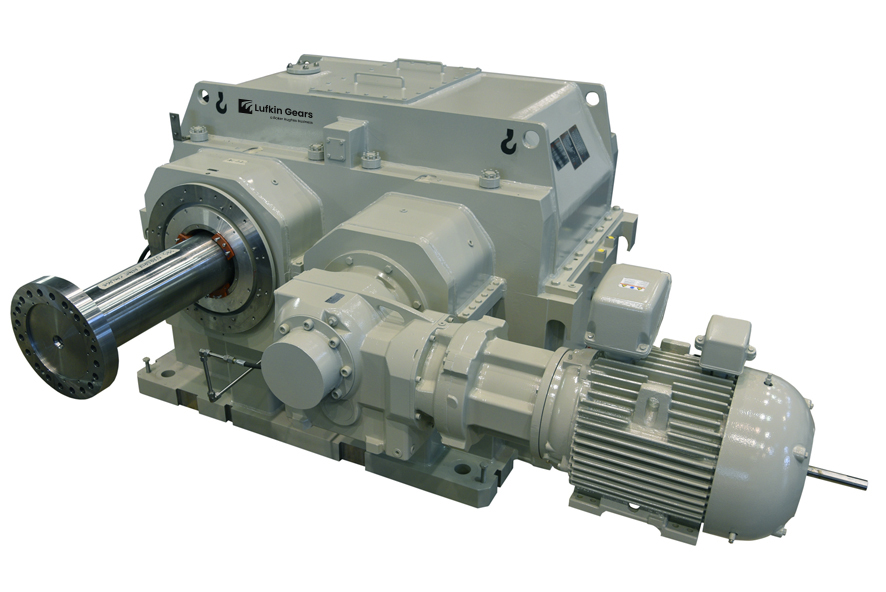

Our Lufkin Gears and Allen Gears brands bring a deep history of industry-leading technology to demanding high-speed mechanical-drive, turbo machinery, and marine-propulsion applications. They continually set the standard for design and manufacturing to meet or exceed the most stringent customer and industry specifications. Our designs include single helical and double helical gearing, and proprietary fluid-film bearing technology to ensure the highest performance and reliability. We use the highest quality materials with advanced processes including through-hardening or carburizing, and precision form-grinding of gear teeth to increase durability, power capability, and efficiency for the most demanding turbomachinery applications.

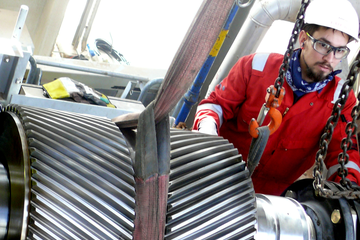

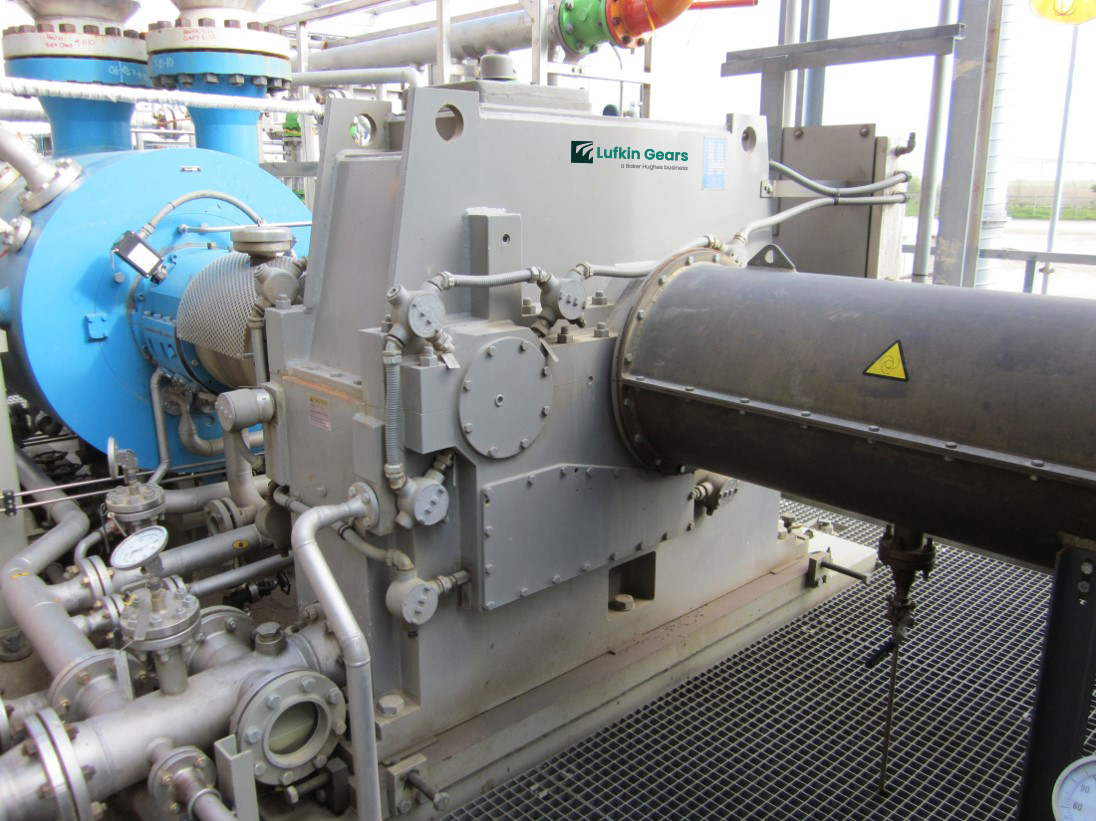

Compressors

Our Lufkin Gears technologies are use on offshore platforms, refineries, and petrochemical plants to drive axial, centrifugal, reciprocating, and screw compressors in various applications. Our high-performance gears are driven by motors, engines, steam and gas turbines at powers up to 90 MW, driving critical service compressors at speeds up to 40,000 rpm. When plant operations demand the utmost in reliability and uptime, Lufkin Gears deliver the reliability to keep production running.

Pumps

Critical pump applications across all industries around the world use Lufkin Gears products to drive axial, centrifugal, reciprocating, and screw type pumps. Pumps are typically driven by motors, engines, steam and gas turbines at powers up to 40 MW and speeds up to 25,000 RPM. For decades, the Lufkin Gears brand has been the standard for these demanding applications.

Generators

The reliability of Lufkin Gears units is known around the world in power generation services for connecting steams and gas turbines up to 90 MW to drive generators that keep plants running and avoid costly downtime. Available with turning drives, integrated clutch and brake systems for synchronous condensing, our gearboxes ensure maximum flexibility to meet any energy requirements.

Fans and blowers

Fans and blowers in every industry segment worldwide are driven by Lufkin Gears units. For applications up to 12 MW, our parallel-shaft gearboxes are used with motors and turbines in API and non-API industrial, chemical, petrochemical, and power plants. Our gears are designed to exacting customer specifications to insure the highest reliability and efficiency.

Test stands

Drawing on decades of proven engineering experience and depth, we can custom design a solution for any test-bench application. Whether to increase production or in developing a next-generation technology, we have the knowledge to deliver a purpose-built solution.

Custom

We can custom-engineer a Lufkin Gears solution for any power transmission application.