Terminals, blending, and transportation services from Baker Hughes help you maximize the profitability of your crude oil stocks and finished fuels, regardless of the market conditions you face. Our wide range of treatment chemistries and emergency response services protect your storage assets, maintain your fuel quality, and add value across the storage and transportation chain in several ways.

Maintain asset integrity

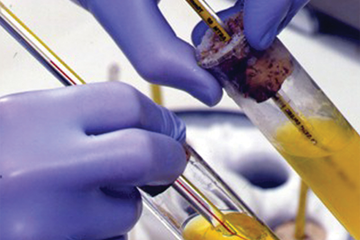

Prevent fouling and damage to your crude oil storage facilities—whether they’re in a terminal, a tanker, a railcar, or a truck—with specialty chemical systems that mitigate corrosion, scavenge H2S, and stabilize the crude to prevent separation during prolonged storage periods.

Improve crude diet flexibility

Boost refinery margins with pour point depressants that make high pour point crudes a viable feedstock by mitigating blockages, wax deposition, and solidification during transport and processing.

Increase fuel values while mitigating safety concerns

Keep your fuels and finished products in spec or boost product value with our dynamic suite of fuel-additive technologies that enhance lubricity, improve stability, mitigate corrosion, eliminate water entrainment, and neutralize H2S and mercaptans.

Quickly respond to fuel spec changes

Meet your business goals and rapidly resolve supply and trading challenges with our quick-response additive treatment programs that help you upgrade your fuels or bring challenging crudes and fuels back into spec—quickly and effectively.

Together, let’s develop the optimal treatment strategies to help you maximize the profitability of your crudes, feedstocks, and fuels in whatever market environment you face.