Highlights

Highlights

Benefits

- Our high-efficiency designs from ambient down to ensure optimal refrigeration and cooling capacity with substantial energy recovery

- Zero-leakage design with a low-temperature cryocooler and magnetic bearings, optimized AMB footprint and weight for offshore applications

- Strong collaboration with SKF on cryogenic engineering and refrigeration systems for AMB optimization, enabling the first AMB for 5.5MW floating LNG

Features

- Advanced use of cryogenic nitrogen liquefaction and technologies, with verified wheels up to 1,000 mm diameter for large-capacity machines

- Wide range of sizes up to 15MW supported on AMB or oil bearings with optional dry gas seals for aggressive gas applications

- Management of energy recovery, coolant and liquefaction turbomachinery, including installation, full-load string testing, start-up, and service

Applications

- LNG feed-gas treatment (onshore and floating)

- Cryogenic gas treatment: dew point control, LPG recovery, refrigeration

- Petrochemical and natural gas: methane, ethylene, syngas, H2 rich process, argon

Overview

Overview

Baker Hughes's turboexpander compressors feature the latest cooling methods and are available in a wide selection of frames and sizes. Extensive in-field experience and state-of-the-art design features ensure the highest performance for simultaneous refrigeration service, cryogenic cooling systems, cooling power, and energy recovery at ambient down to low operating temperatures.

Specifications

Shaft power

0.1 to 15 MW

Max. speed

60,000 rpm

Inlet/outlet flange max

2/48 inches

Max. inlet pressure

250 bar

Temperature range

-270°C to +270 °C

Enthalpy drop per stage

300 kJ/kg

Max. liquid content at suction

1% weight

Max. liquid content at discharge

35% weight

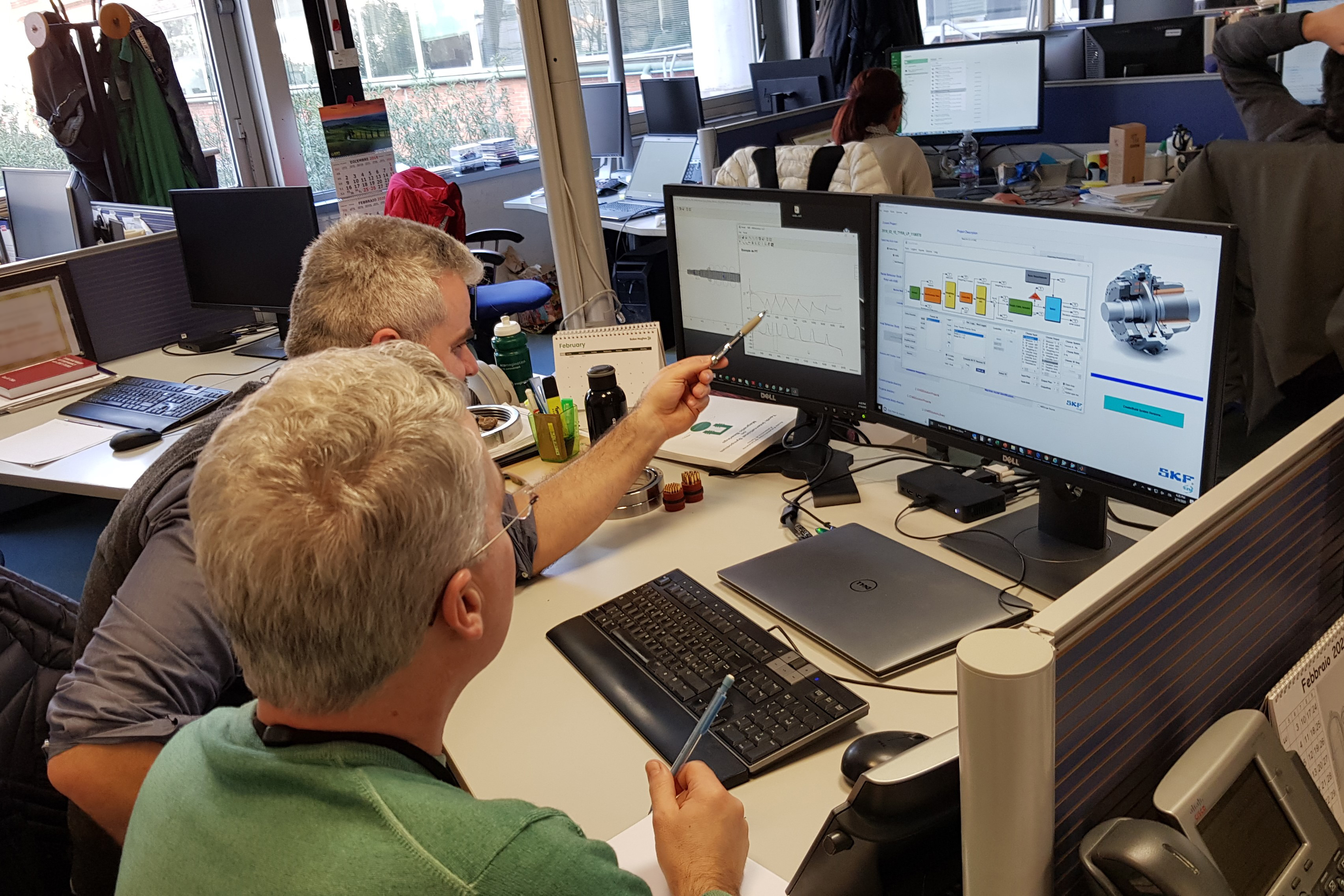

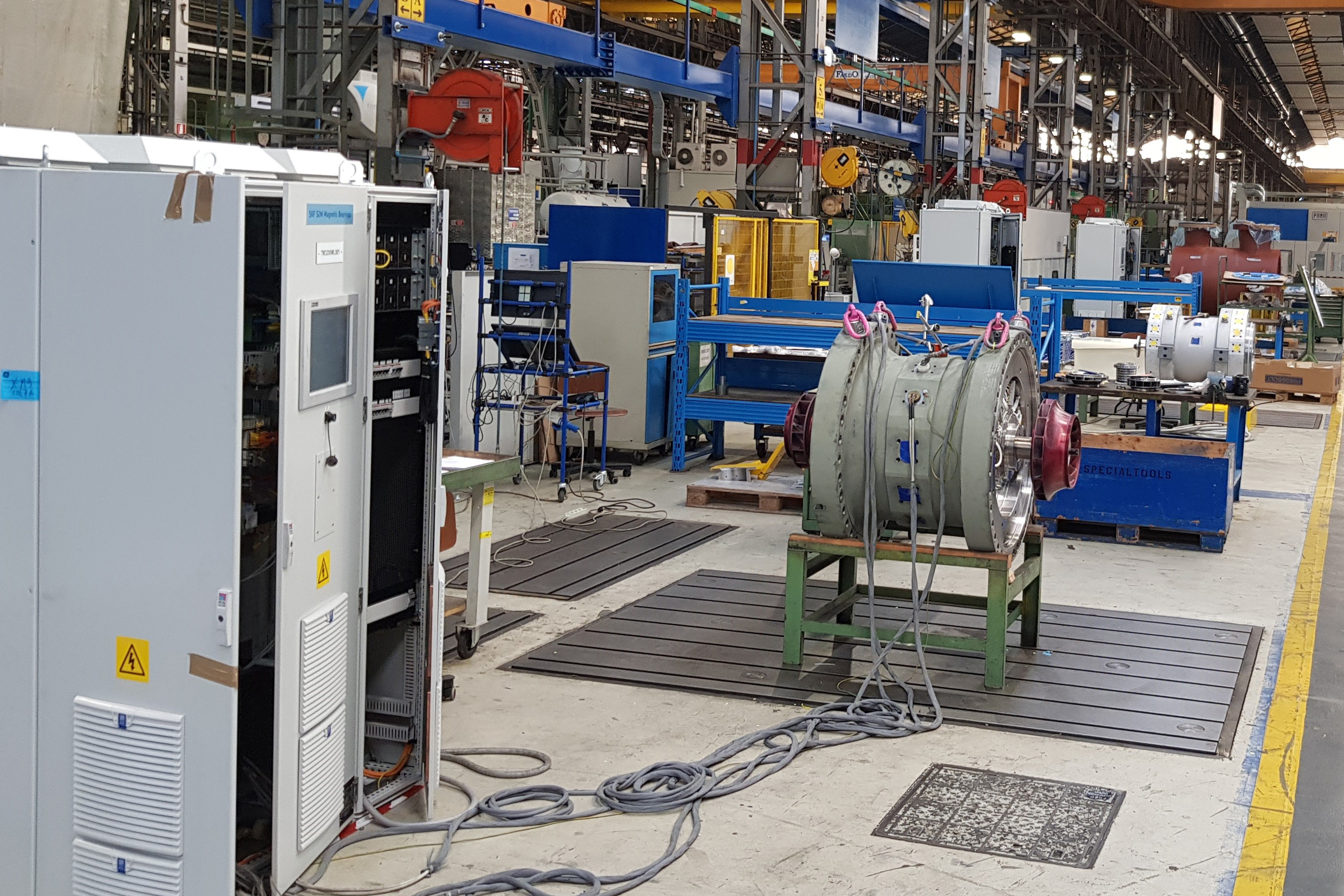

Complete in-house capabilities

For a 2019 offshore platform project in the North Sea involving seven of our single shaft, high-speed moto-compressors with active magnetic bearings (AMB), we also delivered two AMB expander compressors with dry gas seals (DGS). Service is characterized by high H2S content not compatible with magnetic bearings. Hence, the DGS solution was the only way to enable oil-free configuration in sour service. Assembled and tested in-house, our turboexpander compressors leverage our internal capability for magnetic-bearing tuning and testing resulting from the agreement with SKF.