Highlights

Benefits

- Proven to lower torque in lab tests and field applications

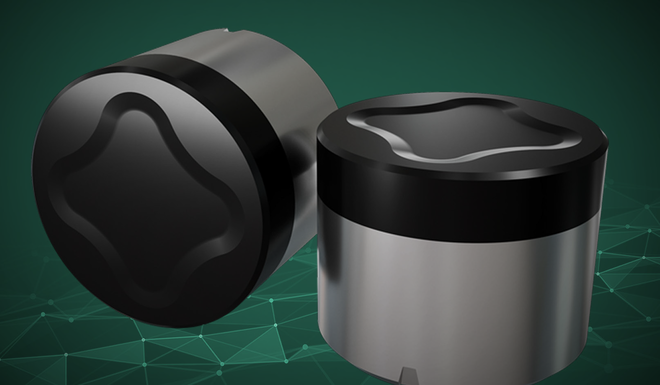

- Non-planar diamond table

- Reduces friction between formation and cutter

- Lowers heat generation at cutter/rock interface

- Maintains sharper edge for more efficient drilling over life of run

- Improved face geometry reduces stresses and improves durability to reduce breakage and chipping

Applications

- Intervals with abrasive formations combined with other types of rock that could introduce impact loading

- Conventional BHA’s and RSS with high-speed motor

Overview

CryoCut™ shaped-cutter technology from Baker Hughes, helps beat the drilling day curve and reduce drilling costs by minimizing friction on the cutter face, improving rates of penetration (ROP), and drilling more efficiently. Run on the Baker Hughes PermaFORCE™ elite PDC drill bit platform, CryoCut shaped cutters use unique non-planar diamond table geometry and polished cutter base technology to enhance performance in key applications.

In more challenging environments, like interbedded sandstones and carbonates, bit performance is directly related to cutters and their ability to withstand heat. CryoCut technology reduces heat generation at the cutter/ rock interface. This lengthens the life of the cutter, which leads to extended runs, fewer bit trips, and reduced overall time to reach total depth (TD).

Stays cooler, runs more efficiently

Lab testing has shown that CryoCut technology generates 25% less heat on the cutter face than conventional planar cutters. This reduction allows the cutter to maintain a sharper edge for longer durations during a bit run. Reducing the heat generation on the cutter face also minimizes cracking and spalling tendencies that can lead to failures and shorten run life.

Improved toughness and durability

An improved stress state delays crack initiation and propagation under loading conditions experienced during drilling. This translates to improved durability, especially when drilling in applications where abrasive formations are mixed with other types of rock that introduce impact loading. The net result is a longer lasting, more efficient cutting edge.