Highlights

Benefits

- Maintain desired well path to target depth (TD)

- Eliminate local doglegs that raise risks of stuck casing and completion strings

- Minimize damage to the bit and bottomhole assembly (BHA)

- Extend run life with higher ROP and fewer trips

Applications

- Soft formations containing hard stringers

- Interbedded formations

- Faulted formations

- Wells requiring extensive reaming to reach TD

Overview

Even the most carefully planned well path can be stymied by a stringer. When your drill bit hits a hard stringer in a softer formation, the sudden change in rock mechanics deflects the drill bit—creating a local dogleg that increases drilling time and costs to target depth (TD).

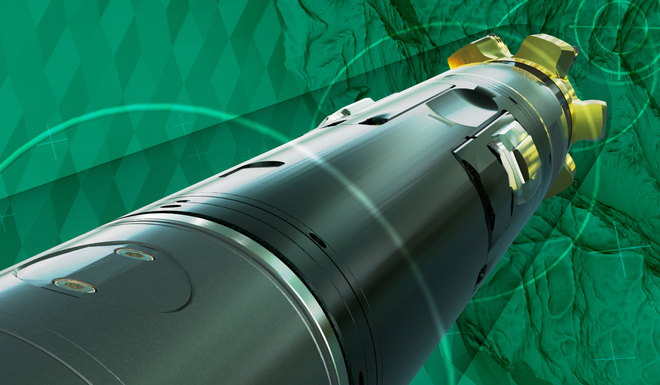

Optimize your drilling efficiency with the i-Trak™ automated stringer detection and mitigation service from Baker Hughes. Part of the suite of proven i-Trak™ drilling automation services, this innovative, early-warning service automates stringer identification to improve drilling performance in several critical ways.

Detect stringers quickly and consistently

The i-Trak automated stringer detection module combines real-time drilling measurements of vibration and load to identify high-frequency torsional oscillations in the bottomhole assembly (BHA). These oscillations, which are the leading indicators for real-time stringer detection, guide your drilling team to take the right corrective actions that maintain the well path.

Efficiently mitigate stringer impacts

This automated service enables teams to react much faster than traditional methods. With earlier detection, your drilling crew can change drilling parameters more quickly and accurately—avoiding excessive local doglegs that risk damaging your bit or BHA.

Eliminate unnecessary reaming operations

Early stringer detection helps you avoid the need for costly reaming operations to smooth out the well path—minimizing invisible lost time (ILT) to get you to TD faster.

Increase penetration rates

The i-Trak automated stringer detection and mitigation service’s advisory capabilities help fine tune your drilling parameters to maximize rate of penetration (ROP) through each stringer. By linking the i-Trak service to your rig’s automated drilling control system (ADCS), you’ll get the optimal target setpoints for RPM, WOB, and surface flow rate for fully automated stringer detection and drilling.

Contact your Baker Hughes representative to learn how the i-Trak automated stringer detection and mitigation service can lower the time, cost, and complexity of navigating your wellbores through hard stringers.