Customized solutions for predicting and preventing production loss

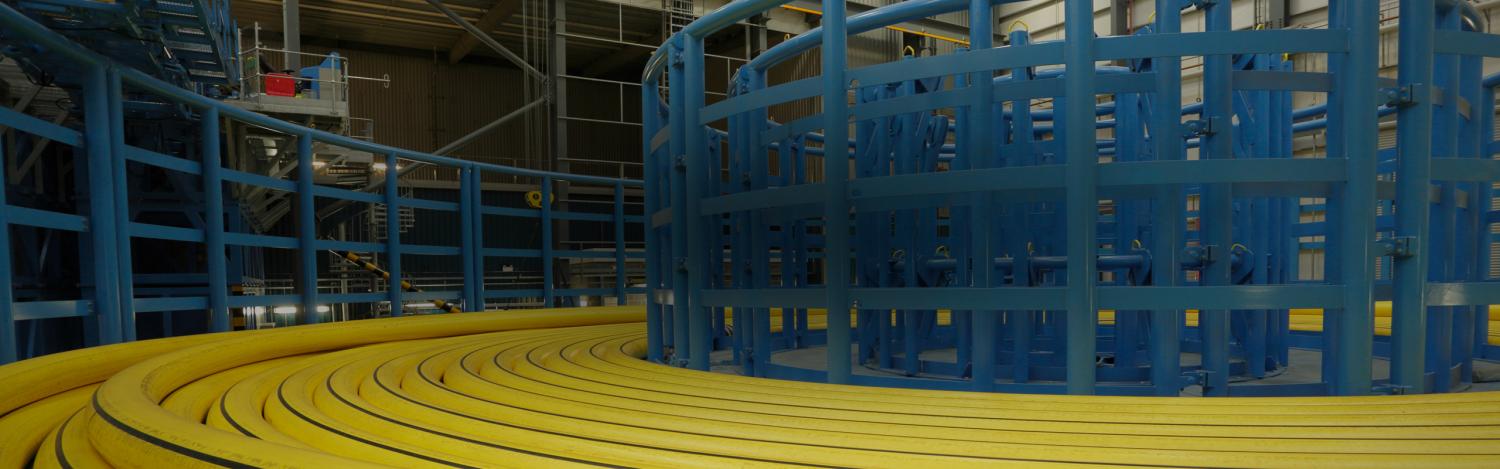

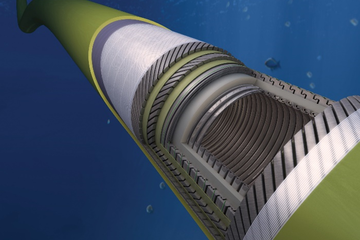

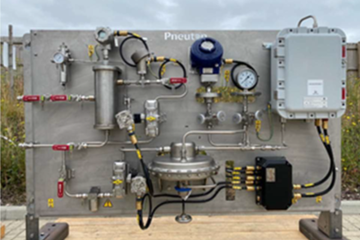

With decades of experience in the design, testing and manufacture of flexible risers and flowlines, Baker Hughes has a unique understanding of how flexible pipe systems perform in operation. We provide a comprehensive range of products and services to assist in the integrity management of these important assets. Our proven solutions include the MAPS® wire stress and wire break monitoring and inspection systems, integrated fiberoptic sensors embedded in the pipe structure, and topsides equipment for the monitoring of polymer and pipe annulus condition. In many cases, our monitoring systems, which are Predix Digital Solution-enabled, can be retrofitted to existing infrastructure, regardless of the original equipment manufacturer. In all cases, we underpin our approach with a risk-based methodology developed specifically to address the attributes of flexible-pipe construction that determine lifecycle performance. Our expertise enables solutions that are customized to meet the particular needs of an installation and its operator.

Our pipe systems’ multiple benefits enable you to:

- Monitor, in operation, the health of tensile and shield layers, and wax build-up

- Predict flexible pipe remaining life

- Offer life-extension opportunities specific to your product

- Prevent loss of production

- Plan preventative action

- Embed at purchase and activate when suitable

- Activate and monitor throughout life cycle

- Allow for on-demand deployment of MAPS FR to monitor wire stress on any flexible pipe