Highlights

Highlights

Benefits

- Excellent availability and reliability: compact mover, designed for long life and ease of maintenance

- Enhanced fuel flexibility with no impact on combustor operability or integrity

Features

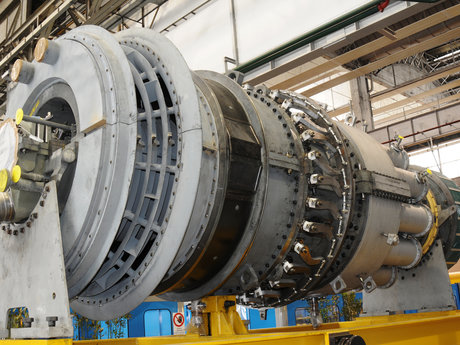

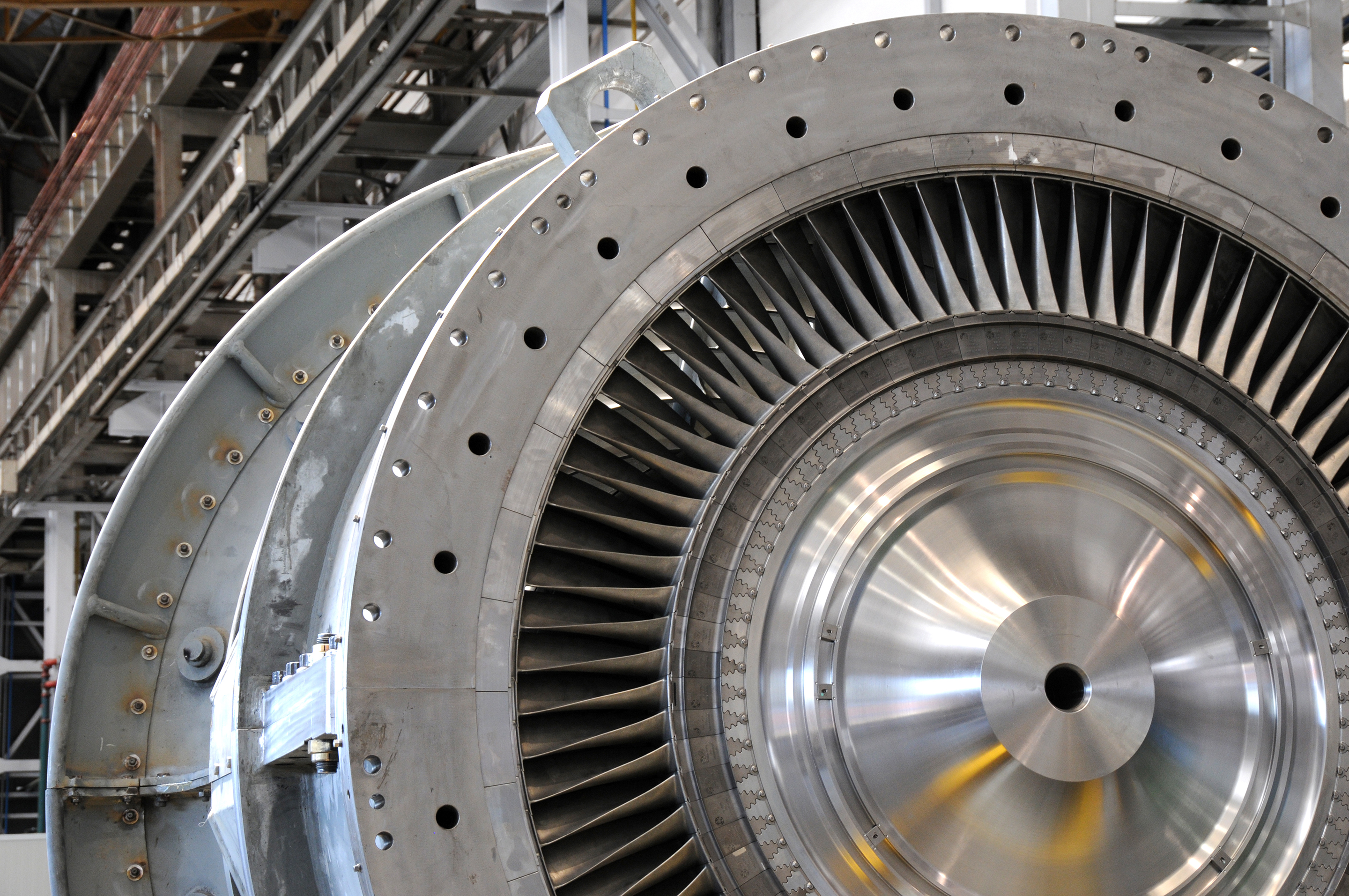

- 16-stage axial compressor adopted on former Frame 5/2B and derived from Frame 5/1N

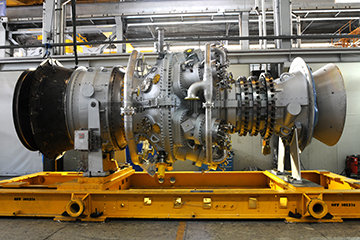

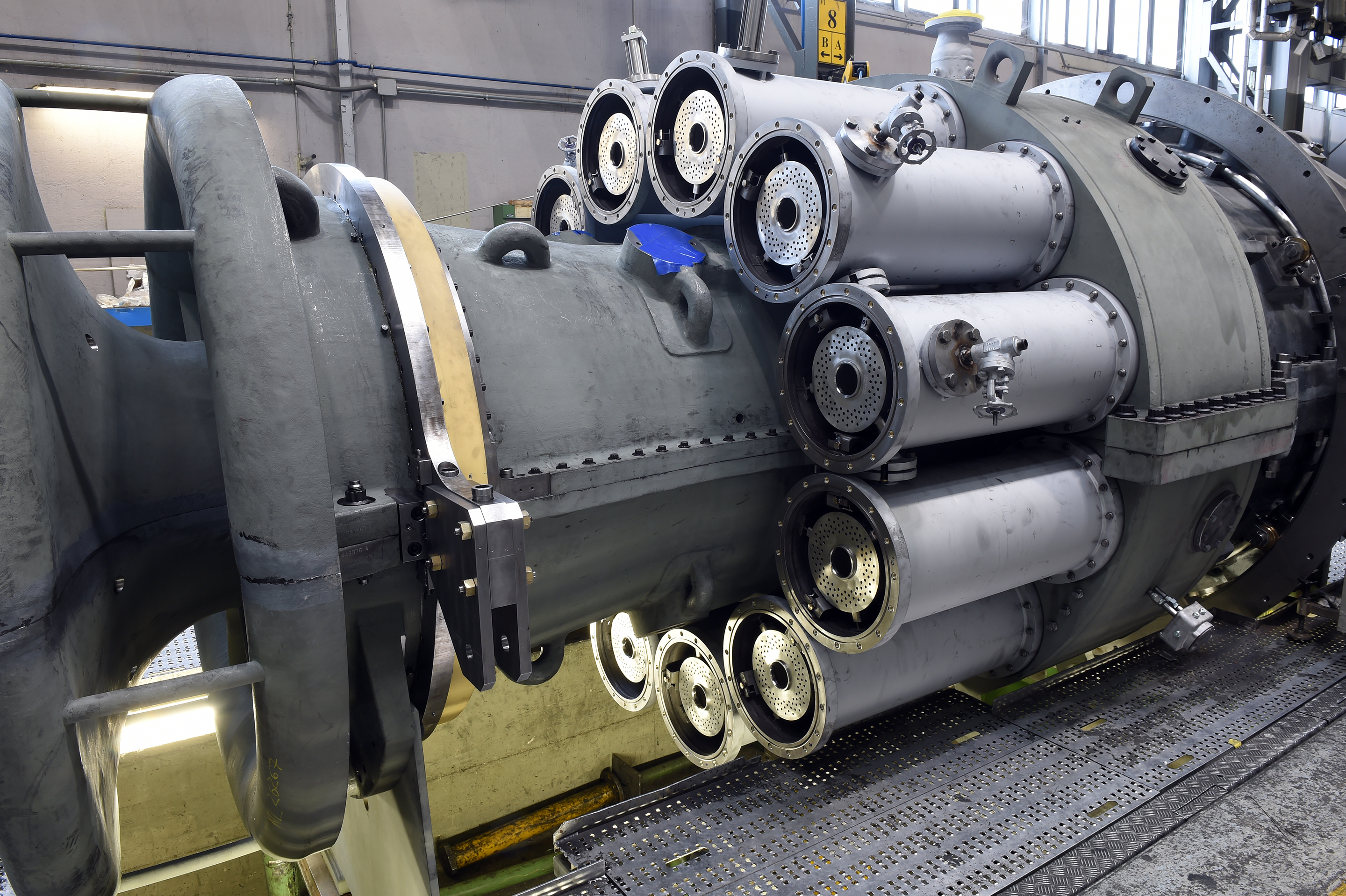

- 12 combustion chambers, dual-fuel DLN1 combustion system available, two-stage turbine with uncooled buckets

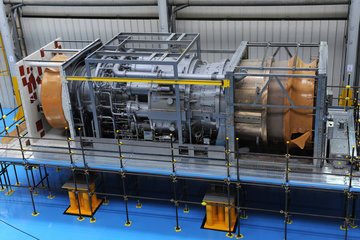

- Two-shaft turbine (high pressure and low-pressure turbines) with variable geometry nozzles between HPT and power turbine

Applications

- LNG

- Pipeline, gas storage

- Refinery, petrochemical, fertilizer

Overview

We have more than 260 units operating around the world with over 25.7 million fired-hours experience. Our first commercial unit has successfully exceeded 200,000 operating hours.

At ISO conditions with natural gas fuel, ambient temperature 15°C, no inlet exhaust losses, sea level, 60% relative humidity. Combustion inspection (CI), and liner and transition piece inspection (LTPI) can be performed at site. Package dimensions exclude driven equipment.

Fuel flexibility and composition

Our Frame 5/2C is capable of operating with a variety of fuel gases, with no combustor operability or integrity issues. It can burn heavy hydrocarbons (25% max ethane content or 20% max propane), inerts (25% max CO2 or 25% max N2), and hydrogen up to 20%.

Power crystal for power increase

An additional 6% of power with lower maintenance intervals can be provided on the standard, LHE, and DLN1 configurations with no hardware modifications.

High availability

The major inspection can be performed at site or, optionally, with module replacement to enable production increase, which is ideal in LNG plants.