Power, communication and commands are managed through e-line cable deployment to a range of purpose-built intervention technologies, each providing precision mechanical functionality. These tools are deployed with or without a tractor depending on the well trajectory or tool requirement, delivering a range of light, precise and highly effective intervention services for wellbore cleanout, completion manipulation and well access & recovery.

Highlights

Benefits

- Precise, cost effective and low risk service

- Light on logistics, footprint, personnel and time

- A comprehensive and modular technology toolbox

Applications

- Cleanout – debris milling, brushing, honing and collection services.

- Manipulation – retrieval and installation of completion components for production control

- Access & recovery - metal milling, completion component repair, fishing and pipe recovery for remediation purposes

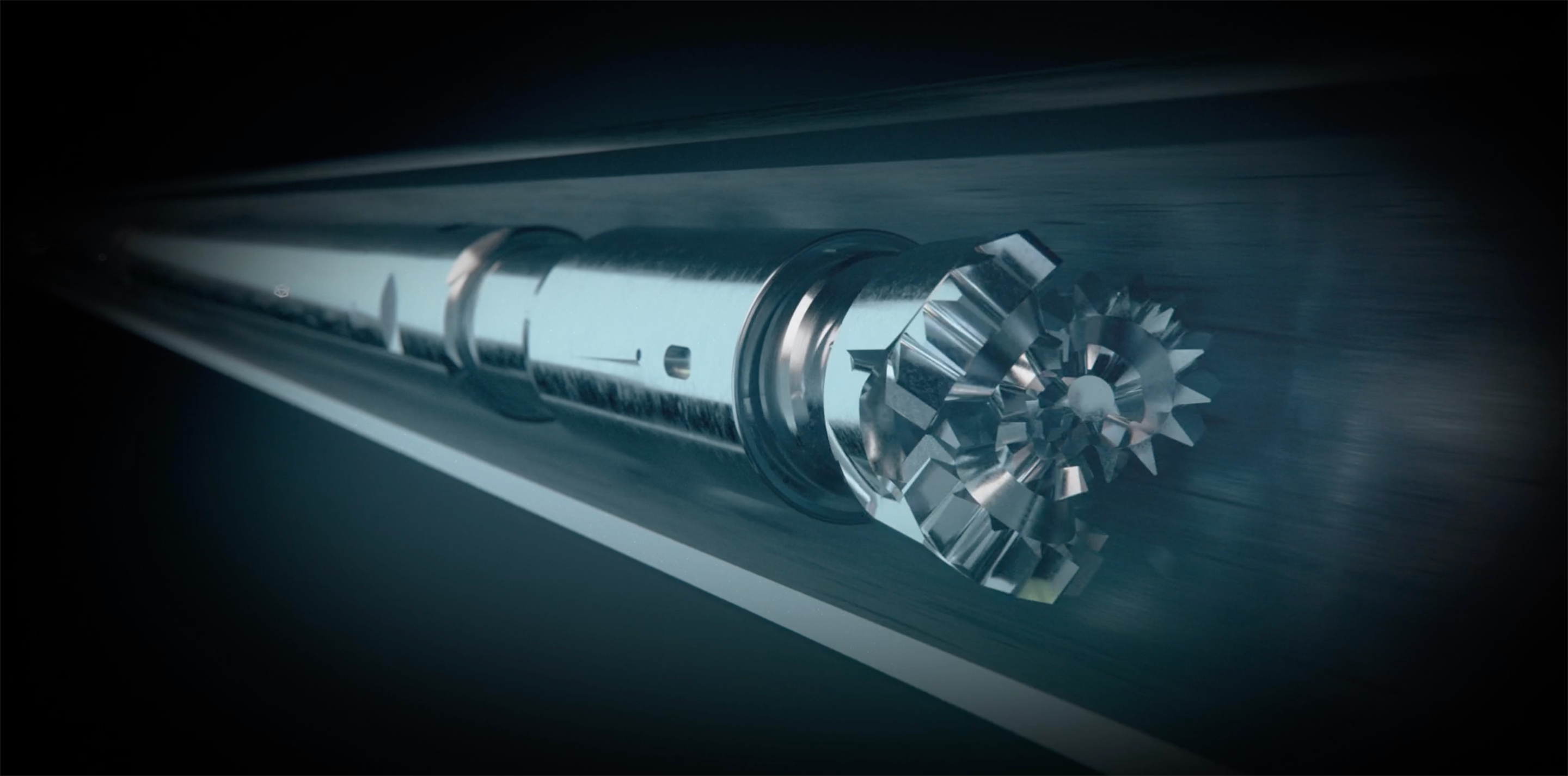

Precision cleanout

The PrecisionCollector is a robust, full system cleanout technology that can remove a wide range of debris types in varying well conditions. It mills, agitates and dislodges the debris downhole, collecting and retaining it in reservoir chambers for transportation out of hole. It is run in combination with PowerTrac or PRIME Tractor for rotational anchoring and providing weight on bit, coupled with a Direct Drive Rotation (DDR) device to generate the required torque and RPM.

In addition, cleanout services also include brushes, hones, debris mills and suction.

The PrecisionSuction tool removes debris by locally circulating wellbore fluids to recover and filter downhole debris into the reservoir chambers. It is suitable for loose debris and complex completion profiles. It is conveyed with the tractor if well deviation requires. The Direct Drive Rotation (DDR) device drives the tools centrifugal pump to generate the localized circulation.

The PrecisionCollector will dislodge and collect extremely high volumes of debris from your well.

Precision manipulation

With adaptable, progressive anchor force and controllable stroker force, the PrecisionStroker and PRIME Stroker are designed to carry-out precise completion manipulation operations, through position control accuracy of 1mm resolution and tailored stroke force control. This, while avoiding inadvertent damage to the completion.

Telemetry and instrumentation provide real-time visibility and control of the manipulation sequences. The strokers can be run in combination with PowerTrac or PRIME Tractor if deviation requires.

With a stroke resolution of 1mm, you will be exactly where you need to be. Demand certainty, whatever the conditions.

Precision access and recovery

We provide a modular technology toolbox that delivers solutions for metal milling, fishing, component re-shaping, and mechanical pipe cutting. These technologies are designed with the intent to rectify wellbore component issues, re-enabling well access for subsequent intervention operations. The e-line deployed tools provide real-time measurement and precise control to minimize time, cost and risk exposure. Also available is the Certia™ pipe recovery log, providing efficient accurate answers for tubular free-point determination.

Intelligent instrumentation and sensors provide in-well activation and control of weight on bit, torque, and rpm .