Highlights

Benefits

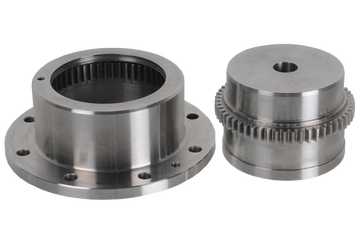

- Genuine spare parts improving machine performance with technology injection, design enhancements and advanced materials

- Collaborative and innovative repair services both on and off site for industry-leading equipment availability and reliability

- OEM Field Service Engineers (FSEs) to execute or remotely supervise site activities with optimal quality, HSE, and efficiency

Features

- Identical or interchangeable parts delivered with maintenance recommendations tailored to the customers individual requirements

- Most advanced technology and repair solutions, with services designed to meet specific customer needs

- Diverse FSE capabilities to adapt to any customer needs; advanced technologies and devices to optimize execution

Applications

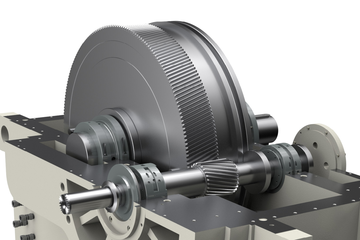

- Genuine OEM spares for entire Lufkin Gears and Allen Gears fleet (~35,000 units worldwide)

- Repair services performed by OEM with comprehensive resources at Centers of Excellence in France and USA

- FSEs perform installation, commissioning, alignment and inspections of Lufkin Gears, Allen Gears, and gears by other OEMs

Overview

As a leading supplier of precision gearboxes for the global rotating machinery market, our dedicated team of service engineers provides timely and expert advice, as well as unrivalled diagnostics and maintenance capabilities to ensure that our customers' gearboxes and associated machinery remain healthy—from commissioning through the full operational life of the plant.

Everything we do adheres to rigorous Baker Hughes quality standards no matter where or when the activities are performed. You can rely on our highly skilled service team for a comprehensive range of repairs and maintenance activities, lifetime extensions, as well as advanced upgrade solutions.

Genuine spare parts

Our approach to spare parts includes new technology injections, design enhancements, and advanced materials to improve machine performance and efficiency. We're committed to providing an excellent service experience too, in particular:

- Timely, competitive quotations

- Component recommendations and original design upgrades

- Swift manufacturing

Refurbishment and repairs

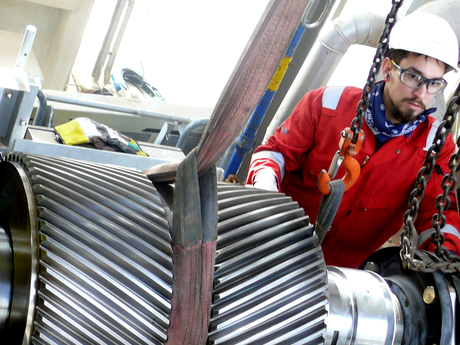

Drawing on extensive operating data from our global installed fleet, and the unique experience of our Field Service Engineers, our COE technologists continually develop more advanced repair solutions that considerably reduce customer maintenance costs and downtime.

For any gearbox repair, refurbishment or upgrade, we first perform an engineering assessment at one of our in-house gearbox repair centers to fully evaluate the equipment/part condition. Based on those expert results, a joint decision is taken with the customer to either repair or replace the defective part. This service ensures that a repaired part will run safely and efficiently, as if new.

Field services

We continually invest to enhance our people's knowledge and skills. Highly qualified and experienced teams can quickly mobilize to deliver expertly planned and executed maintenance anywhere in the world—with the latest technologies and full support of our vast OEM engineering resources and data-driven optimization procedures.

We provide detailed, recommended maintenance schedules for all gearboxes. Our Field Service Engineers perform routine inspections and overhauls as part of ongoing maintenance programs and for unplanned or emergency breakdowns. We also provide expert advice based on advanced diagnostics, to detect abnormal conditions, and rectify to avoid unplanned equipment downtime.

Services shops network

We’ve centralized our US operations into a recently updated facility in Lufkin, Texas, where our flagship technologies were developed nearly a century ago. With a roofed area of ~37,000 m2, this is our Center of Excellence (COE) for repair, remanufacturing, and services.

We also have COE service capabilities in Fougerolles, France, for parallel-shaft and epicyclic gear technologies and serving our customers in Europe, the Middle East, and Africa.

Customers in Asia can take advantage of either COE, as well as our Approved Service Provider network in Asia. All local service providers are fully trained, audited, and approved by Lufkin Gears.

In addition to servicing our own Lufkin Gears, Allen Gears, and legacy Baker Hughes industrial gear products, we continue to provide the same high level of service, for over 30 brands by other OEMs.