Highlights

Highlights

Benefits

- Resist deposition of all manner of scale

- Resist impact damage on pump stages due to solids

Applications

- High sands/solids production environments

- Producing wells prone to significant scale formation

Overview

Get superior scale resistance for your electric submersible pumping (ESP) stages with Armor™ I protective coating from Baker Hughes. Our proprietary fluoropolymer coating resists buildup of asphaltenes and scale while minimizing abrasive wear—ensuring extended run life for your ESP system at minimal expense.

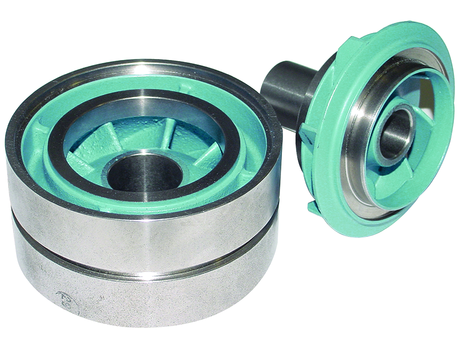

This impact-resistant coating protects critical areas in each pump stage, including impellers, diffusers, the bottom diffuser, and modular thrust bearing components. Armor I is applied to each component through multiple dip baths, which builds the coating to a uniform thickness of up to 0.5 mils (thousandths of an inch).

Once applied, the Armor I coating reduces the risk of pump plugging due to scale, asphaltenes, and moderate abrasives—increasing system uptime while lowering operating costs.

Contact us to learn how Armor I protective coating can optimize the performance of your ESP system.