Highlights

Highlights

Benefits

- Remotely monitor in-field chemical injection to quickly identify and mitigate injection problems

- Effectively manage chemical treat rates and in-field deliveries

- Extend equipment runtime and maximize production

Applications

- Onshore fields with many remote, widely dispersed producing wells receiving chemical treatments

- Remote, offshore production systems

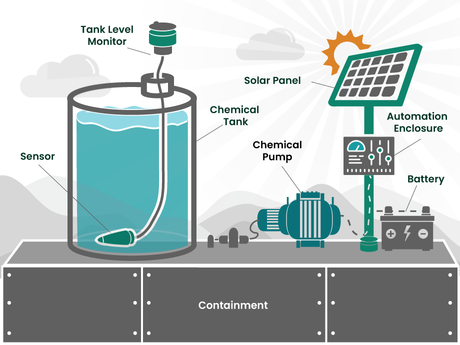

Track and optimize your chemical inventories in the field with SENTRYNET™ remote tank monitoring solution from Baker Hughes.

The system allows you to continuously monitor and track the status of your chemical treatment and inventory levels—on one well or field-wide.

Get assured chemical management with proven solutions

By integrating custom analytics with wireless tank-level monitors installed on chemical storage tanks throughout your field, SENTRYNET remote tank monitoring solution lets you optimize your chemical dosing and delivery in several critical ways.

- Verify chemical injection and usage at each well

- Observe chemical activities field wide and remotely

- Identify low or over-usage conditions in an injection location with real-time alerts

- Get customized web viewing and reporting on chemical dosage and remaining chemical inventories

- Streamline the chemical ordering and provision process

- Reduce trips to remote well sites, limiting unnecessary field expenses and risk to personnel

The automation advances and remote access that the SENTRYNET solution provides, enables you to correct many injection problems and adjust chemical treatments from your own office—saving time, minimizing equipment risks, and lowering your carbon emissions in the process.

Contact us to learn how SENTRYNET remote tank monitoring solution can improve your chemical treatments with minimal cost and risk.