Highlights

Highlights

Benefits

- Can burn multiple fuel-gas compositions; DLN2.5 combustion system capable of single digit NOx emissions from 50 to 100% load

- It delivers 37% efficiency in mechanical drive

- Ideal for combined heat and power, it can deliver 30 MWe of production and 50 tons/hour of steam

Features

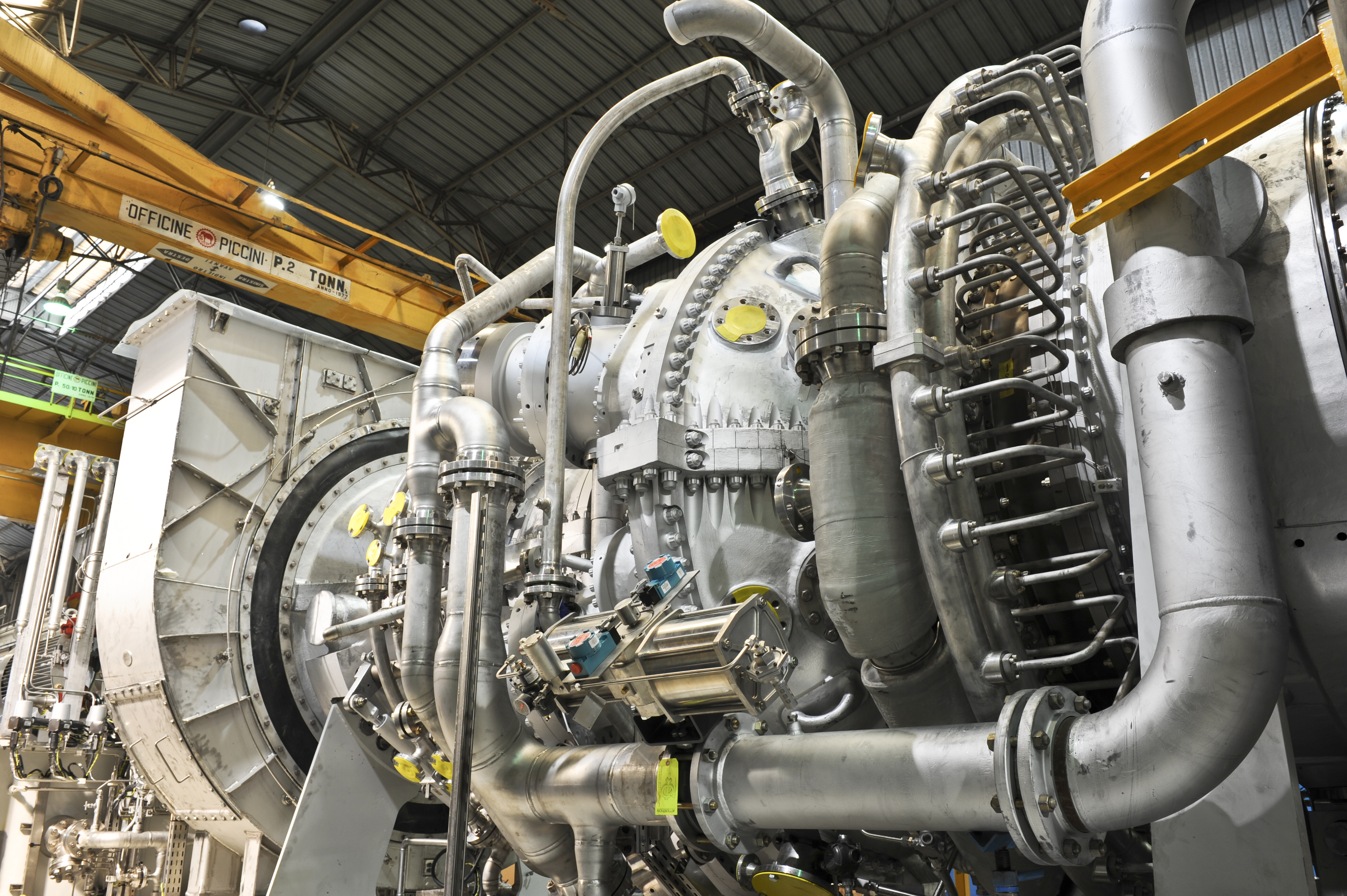

- The axial compressor is scaled up from proven GE10 which has over 100 installed units

- It has a DLN2 F-Class combustion system, of which we have over 750 installed units

- Low-pressure turbine from PGT25+ (>250 installed units), and high-pressure turbine from our Frame 5/2D (>200 installed units)

Applications

- Pipeline, and gas storage

- Refinery, petrochemical, and fertilizer

- Industrial, and combined heat and power

Overview

Overview

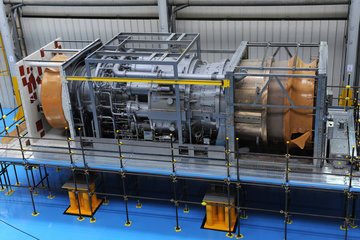

The Frame 5/2E gas turbine design is based on well-proven technologies, combining the best of our gas turbines portfolio with more than 40 years of experience. With over 60 units sold worldwide, 46 units installed, and more than 800,000 hours experience, the Frame 5/2E performs well in any environment—even with extreme ambient conditions.

Specification

Mechanical drive

Power (MW/HP)

33.8/45,300

Efficiency (%)

37

NOx emissions (ppm)

9-15

Exhaust temperature (ºC)

518

Speed (rpm)

5,714

Hot gas path inspection (hours)

24,000

Major inspection (hours)

48,000

Package dimensions (m)

9.5x3.3x4 (LxWxH)

At ISO conditions with natural gas fuel, ambient temperature 15°C, no inlet exhaust losses, sea level, 60% relative humidity. Extended maintenance plan (32,000/64,000) available with fire temperature and power de-rate. Package dimensions exclude driven equipment.

Specification

Power generation 50/60 Hz

Power (MW)

32.8

Efficiency (%)

35.8

NOx emissions (ppm)

9-15

Exhaust temperature (ºC)

518

Speed (rpm)

1,500/1,800 geared

Hot gas path inspection (hours)

24,000

Major inspection (hours)

48,000

Package dimensions (m)

11.9x2.5x7.9 (LxWxH)

At ISO conditions with natural gas fuel, ambient temperature 15°C, no inlet exhaust losses, sea level, 60% relative humidity. Extended maintenance plan (32,000/64,000) available with de-rated fire temperature and power. Package dimensions include driven equipment.

Maximized flexibility

The Frame 5/2E gas turbine can be tailored to customer needs—with 24,000/48,000 hour inspections and 15 ppm NOx in full-power mode, or 32,000/64,000 hour inspections and 15 ppm NOx with lower firing temperature (same hardware).

The turbine can burn multiple fuel-gas compositions: 70 to 100% methane, up to 25% ethane or propane; up to 5% hydrogen, and up to 30% nitrogen equivalent.

Optimized performance

The low-pressure turbine nozzles (stage 3 and stage 4 nozzle) can be adjusted to optimize performance in hot/cold day operation and/or for combined-cycle efficiency if a waste-heat recovery unit is present.