Highlights

Highlights

Benefits

- Eliminate need for wireline with hydraulic actuation

- Delivers selective fluid loss control and well control

Applications

- Circulation while installing a completion

- Zonal isolation during gravel packing operations

- Full production or injection flow post completion

Overview

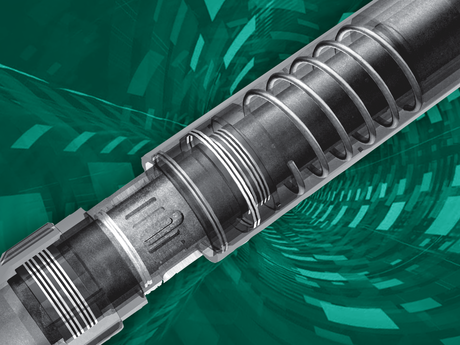

Ensure reliable isolation between your tubing and annulus during completions operations with the CMP Defender and HP Defender sliding sleeve valves from Baker Hughes.

The CMP Defender is an equalizing sleeve that allows selective communication between the tubing and casing annulus for circulation and production. And when run as part of the BOT Defender system in a concentric string, the CMP Defender gives you assured fluid loss control and well control during completion installations.

The HP Defender is a high-performance sliding sleeve that also opens communication between the tubing and annulus, but in more aggressive production environments. The HP Defender’s seal stack is manufactured from proprietary, high-strength, non-elastomeric compounds that are chemically inert and 30% stronger than most commercially available materials—giving you assured flow control in more extreme production fluids.

Both valves are deployed in the closed position and then hydraulically activated by applying tubing pressure to open their fluid ports. When desired, the HP Defender can be closed by again applying tubing or annulus pressure to a hydrostatic piston.

The hydraulic actuation of both valves eliminates the time and expense of a wireline operation. But in the event of a sleeve housing leak or some other problem that prevents hydraulic activation, both valves can be actuated through a built-in mechanical back-up opening device.

Contact us to learn how the CMP Defender and HP Defender sliding sleeves can give you reliable, selective flow and well control.