Overview

Drilling solutions for extreme demands

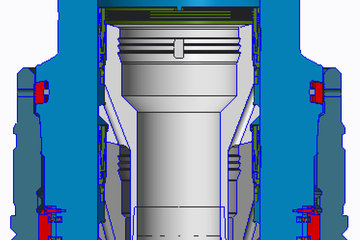

With half a century of field-proven experience and thousands of wellheads installed worldwide, our advanced subsea systems set the industry standard—keeping production flowing in any environment, and meeting our customers’ need for safe, efficient and dependable drilling. Since its introduction in 1991, our customers have relied on the MS-700 in the most challenging conditions.

New levels of reliability

Our new Aptara™ SFX technology takes the core metal-sealing technology to another level of reliability and fatigue resistance. We are extending fatigue life through the improved and recently released H-4FX designs. We offer a wide range of premium connections and casing products, and continue to develop new solutions, such as the Ulti-Max family of gas-tight, weld-on casing connectors, to make your operations safer and more productive in increasingly demanding conditions.

Stand-alone solutions and integrated systems

Our subsea wellhead and premium weld-on connectors are available as standalone solutions or as an integrated system designed for the robust performance you need, with field-proven reliability, efficiency, and versatility. Our complete-system approach enables fast, simple, and economic installation and running, while our portfolio supports subsea drilling operations at all stages of exploration andproduction. Lead times for delivery of a subsea wellhead system range between five months for a standard solution and 12 months for a fully customized solution.

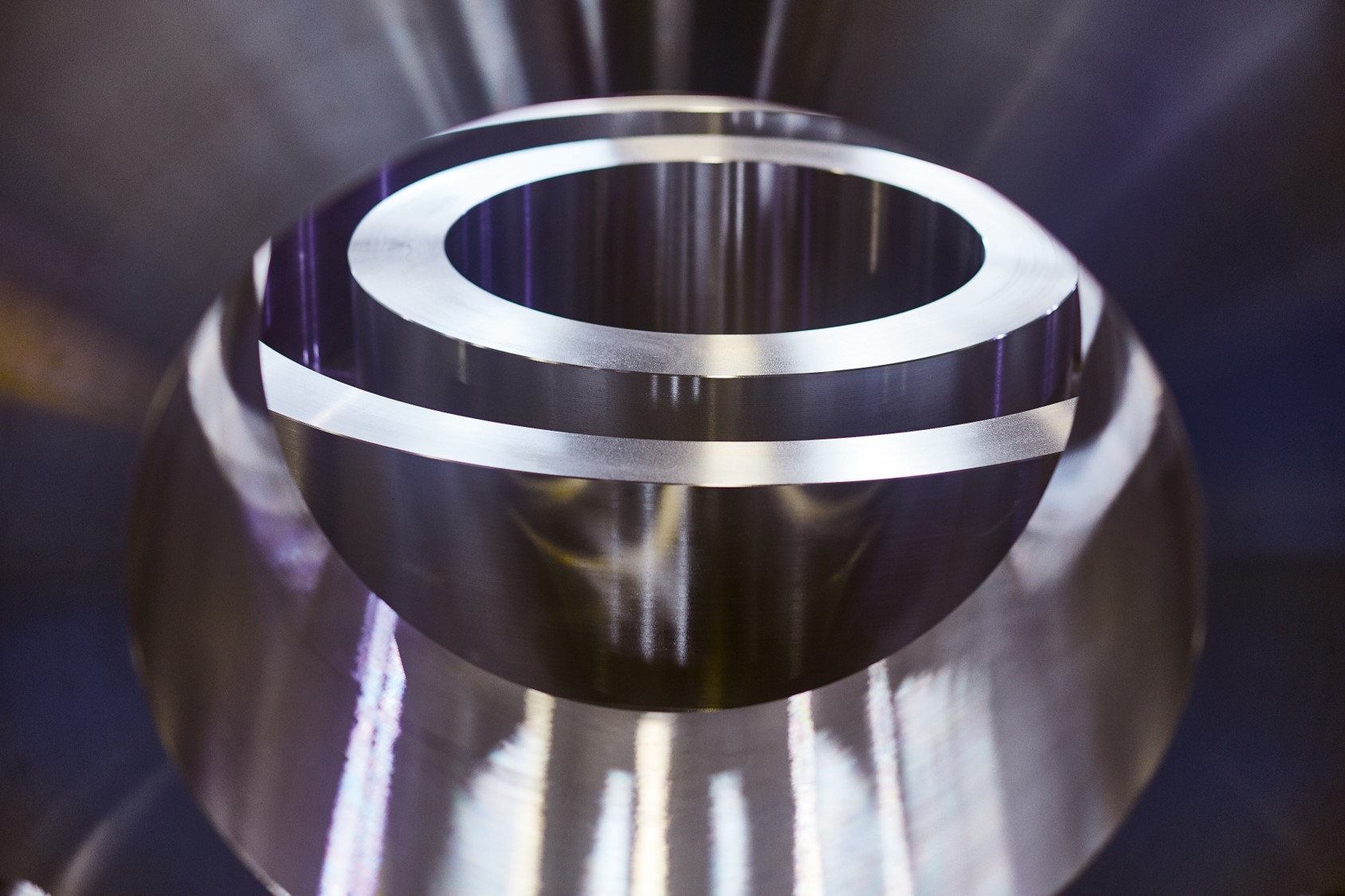

Metal-sealing technology

Our proprietary metal-sealing (MS) technology provides one of the industry’s most reliable wellhead seals—and typifies our engineering excellence. Our multiple independent metal-to-metal seals are significantly more resilient and effective than traditional elastomeric sealing systems, and enable a wider range of operating temperatures and improved gas sealing across our entire portfolio, includingpremium weld-on connectors.

Next-generation sealing technology

Baker Hughes is introducing the next evolution of MS technology, MS-2. The MS-2 seal incorporates all the advantages of our legacy MS solutions and adds an enhanced, single-trip, integrated lockdown solution to provide assurance for all well applications. This provides immediate lockdown for forces of up to 2 million pounds, without the need for a second trip, saving crucial rig time. The MS-2 seal is PR2F tested to 20,000 psi per Group 4 requirements, including a combined-load envelope, and is further tested to 200 load cycles, ensuring life-of-field reliability.

Increased operating life

We continue to invest in and upgrade market-leading solutions. To support operators working in more challenging conditions, we have improved the H-4 profile to provide two to four times more fatigue life. Now available, the H-4FX profile increases the operating life of the interface, and is fully compatible with H-4 style connectors already in the field—so, our customers do not need to worry about change-over management.

Full lifecycle support

With a global network of repair and service facilities staffed with trained experts to provide advanced tools, skills, and solutions, our customers receive full lifecycle support—whenever and wherever they need it.

Reduced capital costs and risk

From installation and maintenance to product enhancements and asset management, we push the boundaries of technology to bring new solutions to market faster and more cost-effectively—keeping our customers ahead of the curve. And by continually partnering with operators and technology and services providers, we enable safe, sustainable, and reliable growth in the offshore industry.

Features and benefits include:

- Industry-proven performance in extreme conditions

- Increased speed, flexibility, and reliability

- Extended life of equipment

- Worldwide support, service, and solutions

- Assured productivity with advanced technology

- Reduced capital costs

- Less risk and downtime

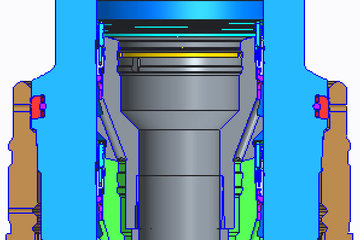

Aptara™ SFX wellhead solution

Our enhanced, standardized, fatigue-resistant wellhead solution (SFX) delivers significantly improved fatigue resistance compared to existing systems.

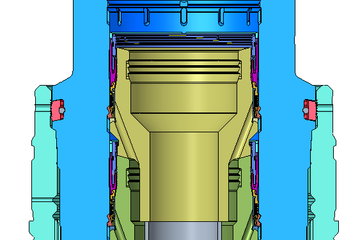

MS-800

The MS-800 can reach deeper well depths with a larger production string, which enables larger completion options.