Overview

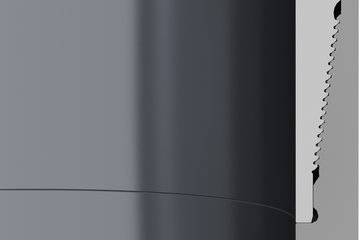

Rigorously tested and cost-effective designsWith lineage of over one million joints installed and counting, our latest weld-on connector, the Ulti-Max™ family is our most rigorously tested solution. Launched in 2015, it performs in extreme upset conditions with a seawater sealing, while delivering improved rig productivity through fast make-up and casing-string installation. The Ulti-Max GT connector has a gas-tight, metal-to-metal internal seal and is available in multiple diameters and thicknesses. It combines all the features of our widely used RL-3M connector with new materials and a more compact, lightweight, and cost-effective design. Baker Hughes also offers a high fatigue-resistant version of the Ulti-Max GT, the Ulti-Max SFX, to meet your gas-tight and fatigue requirements.

Tailored to application needsDesigned with flexibility in mind and tailored to specific application needs, the Ulti-Max GT meets or exceeds all ISO 13679 requirements for tension, compression, bending, and internal and external pressure. It also has a single-thread start that optimizes fatigue performance while minimizing the effects of back-out on seal ability and pre-load loss.

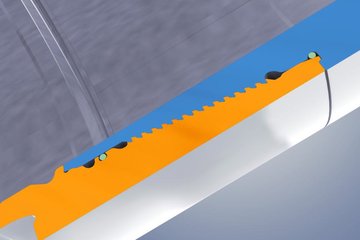

Easy and safe installationAdvanced threads and stress reliefs ensure higher fatigue performance. Large, self-aligning stab guides provide fast, safe installation in 3.5 turns, and large stress-relief grooves prevent hydraulic locking. Our patented new anti-rotation keys design is easily and safely installed in less than 30 seconds with no special tools for between 49,500 and 62,500 ft-lbs of torque capacity.

Features include:

Typical lead time of five monthsThe make-to-order Ulti-Max connector tubular joint can be delivered in five months.

|