Overview

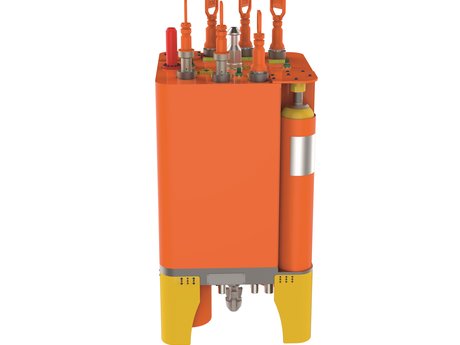

Safe and reliable subsea controlWe know that the safe and efficient control of subsea production systems is at the top of your priorities. That’s why we have ensured that ModPod, our subsea control module (SCM), is one of the most technologically advanced, versatile, and reliable control-system components available. ModPod is a multiplexed, electro-hydraulic SCM typically used for subsea tree and manifold-mounted applications. It is also used for wider applications such as subsea interventions, workovers, safety systems, and subsea isolation valve control. It ensures the stable and reliable control of subsea valves, while providing the communications and sensor data read-back required to maintain optimal operational efficiency.

Fast delivery and proven track recordModPod’s modular, configurable design, in conjunction with our structured engineering and quality processes, enables short cycle times and certainty of schedule. That means we can deliver make-to-order variants as fast as nine months.We also offer a fully configured solution.

Potential 99% production availabilityCommon ModPod components across all applications also means repeatable build processes, improving reliability at the core of your subsea system. Every manufactured unit is subjected to hyperbaric testing to 9,842 ft (3,000 m). Using standard components allows us to volume-source them, extending reliability into the supply chain and bringing down the capital cost of this unit in your production systems—a principle that extends to the SemStar5™ units in the ModPod. To date, we have delivered more than 1,000 ModPods to our customers and the SCM has a proven track record across a range of high-functionality applications, hitting production availability targets of over 99%.

Reduced total cost of ownershipThe ModPod is API17F, SIIS and IWIS compliant. The standard make-to-order configuration supports 24 control functions, sufficient for most subsea production applications. Variants can also be configured to control up to 42 hydraulic functions—enough even for subsea workover-control applications. The ModPod also offers integral accumulation and hydraulic filtration, which removes the need for separate subsea accumulation modules, reducing the total cost of ownership over asset lifetime and improving control-system reliability.

First-class heritageBaker Hughes has been designing and manufacturing directional control valves (DCV) for use in the ModPod SCM for over 25 years. The product has undergone continual development and design validation to meet ever-increasing demands for reliability, availability, and safety in control systems. Our DCVs are qualified to 10,000 psi with a variety of control fluids. Validation work is continuous and the product line is continuing to evolve to meet the requirements of high-pressure, high-temperature (15,000 psi and 350°F) and 20,000 psi field requirements.

Common features of the ModPod series:

VetcoGray ModPod packageThe VetcoGray ModPod package requires minimal one-time engineering between order confirmation and integrated-system factory-acceptance testing.

VetcoGray ModPod customThe custom option is the most flexible and configurable SCM package, with many options available for functionality and specification. After factory acceptance testing, the VetcoGray ModPod custom package is fully integrated with the complete production control system at EFAT and site-integration tests before subsea deployment.

|