Crafted under pressure to withstand pressure

Our portfolio of premium connectors and casing includes a wide range of precision connection systems. With more than 20,000 joints installed per year, our connections are designed for simple and quick deployment.

Conductor and casing connectors are designed and verified by extensive testing and analysis for compatibility with the strength and capacities of the pipe. These connector pipes enable quick, accurate placement and virtually eliminate cross threading in the case of threaded connectors. Metal or resilient seals in our threaded connectors ensures high-pressure sealing for all applications with optimal torque for increased operational safety and makeup reliability.

Field-proven technologies

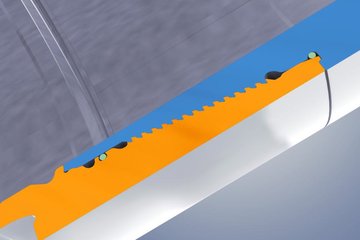

Our latest weld-on casing connectors include the Ulti-Max GT, Ulti-Max SFX, and RL-SFX. Built using field-proven technologies, with new materials and advanced features, they meet the most demanding performance requirements.

Designed with flexibility in mind and tailored to specific application needs, Baker Hughes connectors feature advanced metal-to-metal sealing for high dependability under extreme conditions.

Features and benefits include:

- Higher-grade materials for more robust performance

- Stress analysis to assess protection against excessive yielding, with consideration of large deflection

- Advanced metal-to-metal sealing for extreme reliability

- Customized with precise specifications for each application, pipe size, coating, handling, circulation and installation to fit your needs