Overview

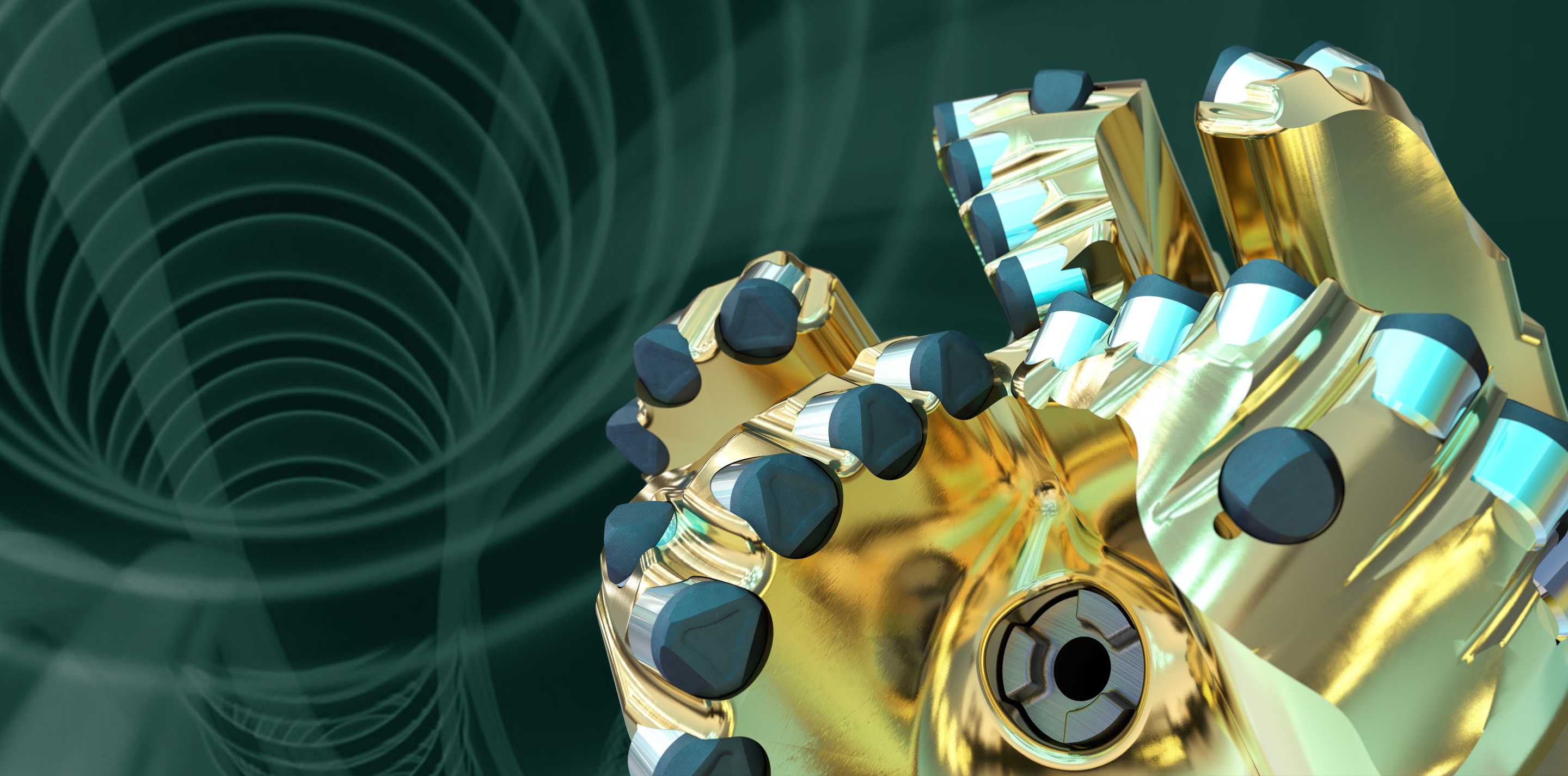

Shaped-cutter technology from Baker Hughes can help improve the speed and length of your drilling runs. Each of our shaped cutters has been painstakingly designed, engineered, tested, manufactured, and optimally placed to deliver specific performance improvements in specific formation types.

Benefit from a portfolio of cutting-edge shape designs

Each Baker Hughes shaped-cutter is custom-engineered to deliver a range of performance improvements under different drilling conditions. These include:

- StabilisX™ shaped cutters which are engineered to avoid heavy-impact damage in—and extend runs through—tough, interbedded formations.

- ShockWave™ shaped cutters are often deployed in interbedded formations as they provide a durable edge and can also help lower friction to prevent thermal damage or chipping.

- CryoCut™ shaped cutters reduce friction while drilling through hard, abrasive formations where thermal damage and chipping are the dominant failure modes. These cutters provide the high efficiency and wear resistance because an engineered relief deflects cuttings away from the working edge of the cutter to keep the cutter cooler for longer.

- Prism™ shaped cutters provide point loading for more efficient drilling and are engineered to reduce friction, for greater cooling at the cutter tip. They’ve proven extremely effective at helping drive penetration rates across a wide range of formation types, even at lower weight-on-bit.

- Apex™ shaped cutters are perfect for drilling tough, ductile formations — especially at higher mud weights or with restricted WOB.

- Lancer™ shaped cutters cut with a more efficient point loading effect compared to Prism cutters. They are also more durable than Apex cutters, allowing them to be used in applications with more interbedded formations with carbonates, anhydrites, and high MW shales.

Count on a company that won’t cut corners on design and testing

Our drill bit experts use advanced 3D modeling tools to refine each shape based on how we are attempting to improve performance in a specific application or formation. Once we’re happy with the initial design, we manufacture prototypes and test them against a variety of formation types under specific drilling conditions in a device that can mimic downhole weights and pressures. This lets us further refine each shape until we are confident that it will deliver the performance improvements you need.

Then, once a new design goes into our portfolio, we test and model its exact placement on the bit to deliver the best possible results. We can even mix and match multiple shapes in multiple locations to best match an application for the customer’s desired outcome.

Contact a Baker Hughes representative today to start a conversation about how our shaped-cutters can help you drive well construction efficiency with longer, faster drilling runs.