どのように現像プロセスとフィルムアーカイブの特性を確認するか?

Besides exposure technique, many aspects influence the quality of the final radiograph. An important factor is the development system. Monitoring and quantifying the proper functioning of a development system is an essential part of quality control, as a properly exposed radiograph can be spoilt if the processes that follow are performed incorrectly. For the monitoring of the development process and archival properties of X-ray-films, Agfa has produced two methods: the so-called PMC-strips, and the Thio-Test. Both methods are based on the international standard ISO 11699 part 2, and the European standard EN 584 part 2, which describe a standard development process and the means to control its execution.

PMC-strips to check the developing process: To facilitate ongoing quality control, and ensure compliance with existing standards on systems classification, certified PMC-strips are used to monitor the development process. PMC is short for Processing Monitoring Control.

The purpose is to:

• demonstrate conformance with the standard film system as described in the standards ISO 11699 or EN 584

• demonstrate the consistency of the development system

• monitor and promote uniformity of the various development systems in different locations

• initiate timely corrective action if deviations occur

PMC-strips are film strips that have been “ pre-exposed” in a regular step-pattern by the supplier, under special conditions and within narrow tolerances, but have not as yet been developed. They are supplied with a certificate of compliance with EN 584-2 and ISO 11699-2. In the development system to be checked, a PMC-strip is processed routinely in a way identical to a normal radiograph. Finally, the various densities are measured with a densitometer.

A PMC-strip as shown in figure 2-10 has to be used whenever the chemicals in an auto- matic or manual processing system are replenished or changed. It is also advisable to use a PMC-strip regularly, but at least once a month, for a routine check of the development system.

A calibrated densitometer measures the following steps:

D0: fog and base density ( 0.3)

D3: density of step 3

D7: density of step 7 The reference values according to the corresponding certificate are Sr and Cr. The following calculations are then made:

• Sensitivity index Sx = D3 – D0

• Contrast index Cx = (D7 – D3).Sr/Sx

The system is acceptable if the following criteria are met: a. D0 = 0.3 b. Sx has a value 10 % of Sr c. Cx has a value between Cr +15 % and Cr –10 % If one or more of these criteria are not met, the development process must be adjusted.

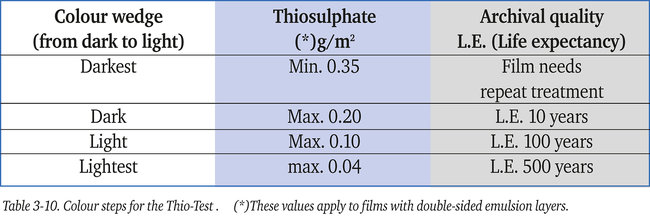

Thiosulphate-test to check film archiving properties: The archival properties of a radiographic image must also be determined in accordance with the standards ISO and EN by analysing the quantity of residual thiosulphate in the film’s emulsion layers. This quantity depends on the thoroughness with which the fixing and rinsing processes have been carried out. For storage over a period of 100 years, 100 g/m2 is allowed; for a period of 10 years dou- ble this figure is allowed, see table 3-10. These values are difficult to measure however. The so-called Structurix Thio-Test, developed by Agfa, is a very useful and quick method to quantify film-keeping properties in practice.

The unexposed area on the PMC-strip shown in figure 2-10, apart from providing a reference for fog and base density, also allows for the Thio-Test to be carried out. The components used for this test are:

- The Thio-Test colour step-wedge

- A dropper-bottle of Thio-Test reagent The reagent consists of a 1 % silver nitrate solution in demineralised water. The working method, which only takes a few minutes, is as follows:

- apply the test liquid (reagent) to an unexposed part of undeveloped, dry film

- allow to soak for 2 minutes, 15 seconds

- remove excess liquid with absorbent paper

- leave to dry for 1 minute before treating the reverse side

- repeat the above procedure on the other side of the film, in exactly the same spot.

Evaluate as follows, within 30 minutes:

- the test zone of the film is put against a white background

- the Thio-Test colour strip is put on the film, as close to the spot as possible

- the colour step of the wedge that resembles the colour of the test zone closest, is regarded definitive for life expectancy.

A regular Thio-Test provides early detection of deficiencies in the development process, for example exhausted fixer solutions, irregular water supply or insufficient rinsing, and so prevents poorly processed films being archived.

What are best practices with regard to the source-to-film distance?